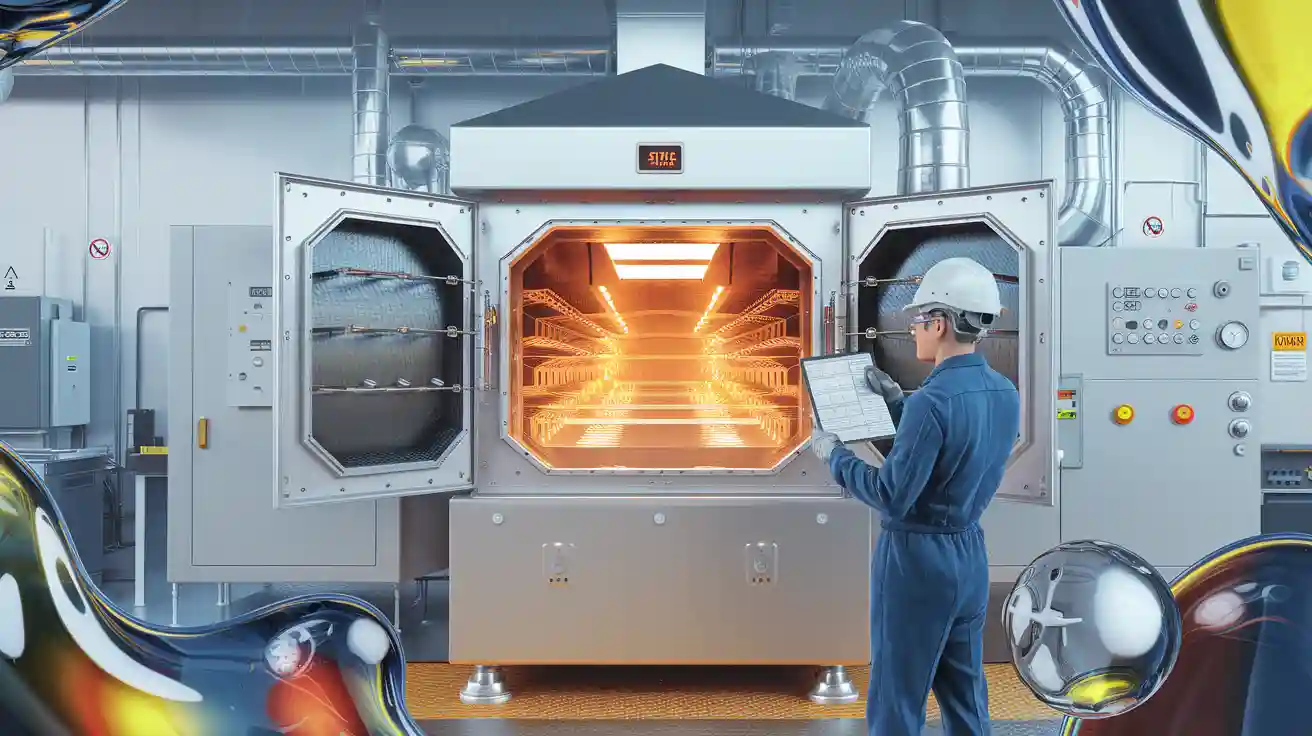

What to Look for in an Aluminum Brazing Furnace

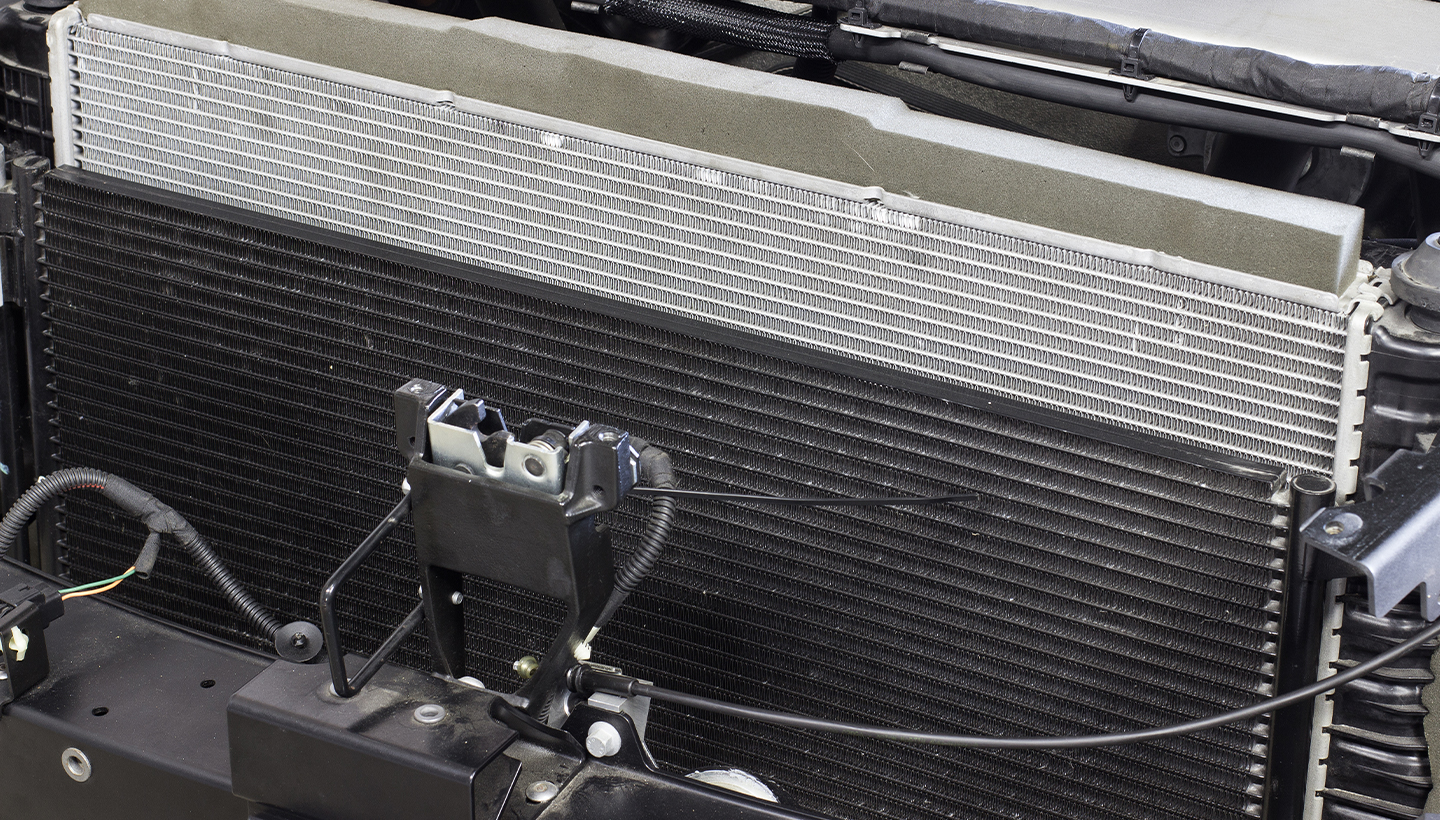

Selecting the right aluminum brazing furnace requires understanding your specific production needs and quality standards. You need to consider your desired output and the level of quality you expect. Manufacturers look for a brazing furnace that prevents issues such as pinholes and warping, while also ensuring strong, durable joints. Achieving this relies on precise control of both atmosphere and temperature. Many industries require an aluminum brazing furnace that can handle a variety of product shapes and sizes, as well as rapid heating capabilities. It’s also important that the brazing furnace integrates seamlessly with other equipment, such as degreasers or fluxers. Consistent heat distribution and stable control are essential for optimal brazing results. Companies rely on a brazing furnace that delivers all these features to produce high-quality aluminum components.