China Car Radiator Machine Manufacturers

Development

Extensive experience in developing automotive radiator machines and molds. Let's collaborate on your product needs.

High Quality

Strict quality control system, strict processing and assembly process, and professional testing laboratory.

Manufacturing

We have advanced automatic machines and a strict processing and assembly process.We can manufacture all the Electrical terminals beyond your demand.

100%Service

You have tailor-made machining solutions for users and bulk and custom small packaging, FOB, CIF, DDU, and DDP. Let us help you find the best solution for all your problems.

Who We are & Why Choose Us?

Shenzhen DAG radiator machine co ltd. (DAG) is the world’s most trustworthy Chinese radiator machinery manufacturer. It is dedicated to radiator core builder machines, radiator fin forming machines, aluminium brazing furnaces, manifold automatic slotting machines, and radiator plastic tank crimping machines. After more than ten years of innovation and development, DAG has grown into a world-renowned brand suitable for beginners and professionals.

- High quality, best price

- Provide OEM&ODM services

- Provide free samples, solutions, and technical support.

- Guarantee the quality of the machine is 100% qualified.

- On-time delivery for every customer

What Do You Need?

Before owning a radiator machine, whether a novice or an expert, you should understand the purpose of buying a radiator. Is it a new factory, or is new machinery being added or replaced on an existing production line? What materials do you need it to handle? What is the thickness, length, and width of copper or aluminium? Once you know your goals, needs, and budget, you can purchase the best radiator machine for your business. DAG offers everything you need to start, including machines and solutions, instructions and demos, prices and deals, software and documentation.

For tailored assistance, submit your request using the form below, and DAG will help you find the right machine for your needs!

Get Detailed Solution

Request A Radiator Machine Solution Based On Your Needs & Budget

Our company radiator machinery

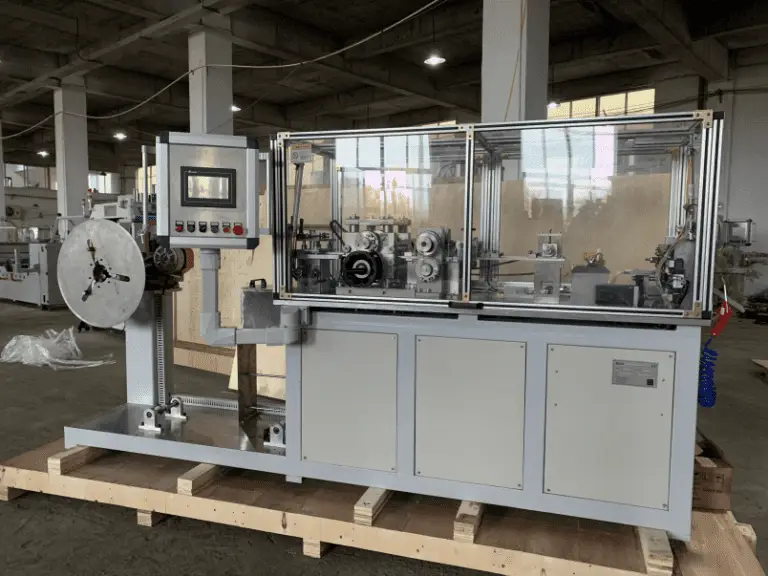

Radiator Core Builder Machine

Core-making machines include condenser core-making machines, intercooler core-making machines, heater aluminum core-assembling machines, water tank core-making machines, and aluminum radiator core-assembling machines. It can adapt to different sizes of magnetic cores and can be applied to different types of tubes.

Radiator Fin Forming Machine

The aluminum radiator fin forming machine makes aluminum fins for fin and tube heat exchangers, including aluminum radiator fins, inter-cooler turbulence fins, condenser fins, and evaporator fins in automobile air conditioners.

Radiator Plastic Tank Crimping Machine

The radiator plastic tank crimping machine connects the plastic water chamber and the radiator core closely through the air cylinder drive to ensure that the coolant circulates in the radiator. This is the last process to complete the radiator manufacturing.

Collecting Pipe Auto Punching Forming Machine

The Condenser Header Pipe Punching Machine is specially used for making aluminum pipes for parallel flow condensers by punching holes in them. It is necessary equipment for the parallel flow condenser production line and is used for producing round collecting pipes or abnormal-shaped collecting pipes of parallel flow condensers.

High Speed Auto Radiator Fin Making Machine

The fin-making machine is controlled by a PLC, AC servo system, and touch screen. The servo motor controls the fin-forming unit, pitch-forming device, collection device, and fin-pulling device separately. Independent servo motors drive the counting device and the cutting device.

150-600mm/Min Aluminium Radiator Brazing Furnace

150-600mm/Min Aluminium Radiator Brazing Furnace is mainly used for brazing aluminum parts in a protective atmosphere. It is suitable for the mass production of aluminum radiators such as parallel flow condensers, laminated evaporators, and automobile water tanks.

Side Plate Auto Forming Machine

The machine can have the coiled strip go through a straightening device, edge forming, punching, pressing into arc structure at both ends and cutting off automatically by the dimensions.

Different types of tooling are used to make another side plate: simple operation, high automation, stable and reliable forming quality.

Copper Radiator Fin Forming Machine

The radiator fin-making machine produces copper heat radiation flat fins. Its tooling can make louver or convex ribs, punch holds, and roll ribs. The servo-driving system has high positioning accuracy, which assures cutting accuracy.

Hotspot machine

Radiator Crimping Machine

The Egyptian customers have purchased a 1.5 KW Radiator Plastic Tank Crimping Machine.

Radiator Core Builder Machine

The Iranian customer is very interested in the 4-row aluminum automotive radiator core builder machine and wants to buy it.

Radiator Fin Forming Machine

The European customers have purchased a 300M/Min Double Tray Aluminum Radiator Fin Forming Machine.

Automobile radiator water tank production line

Car radiator production process

Radiator Fin Making Machine

Show results