Leading manufacturers pick aluminum brazing as the best way to join metal without welding. It is chosen for being fast, saving money, and making strong joints. They use the aluminum brazing furnace from DAG to help with making aluminum radiators, heat exchangers, and cars. In many cases, aluminum brazing has clear benefits:

- It uses lower temperatures than welding. This helps stop bending and keeps the base metal strong.

- The process makes joints that are smooth and go all the way through. It works well even in tricky or tight spots. This makes it the best way to join metal without welding.

- Aluminum brazing keeps electricity and heat moving through the metal. This is important for main uses where good performance is needed.

These good points make the aluminum brazing furnace a top choice for many jobs.

Key Takeaways

- Aluminum brazing uses less heat than welding. This helps keep the metal strong. It also stops the metal from bending or warping.

- Brazing makes smooth and sealed joints. These joints are good for thin, delicate, or tricky metal parts.

- Manufacturers save time and money with brazing. It is easier to use machines for brazing. It also needs fewer skilled workers.

- Brazed joints spread stress out evenly. This makes them strong. They are less likely to crack when under pressure.

- DAG’s aluminum brazing furnaces control temperature very well. They save energy and are easy to use. This gives steady, good quality.

- Brazing can join different metals easily. Welding cannot do this as well. This makes brazing great for many factory jobs.

- Car, heat exchanger, and airplane industries like brazing. They choose it for its trustworthiness, accuracy, and money savings.

- Picking brazing or welding depends on what the part needs. You must think about strength, size, and heat sensitivity. Brazing is best for thin or delicate parts.

Brazing vs Welding

Process Comparison

Heat Input

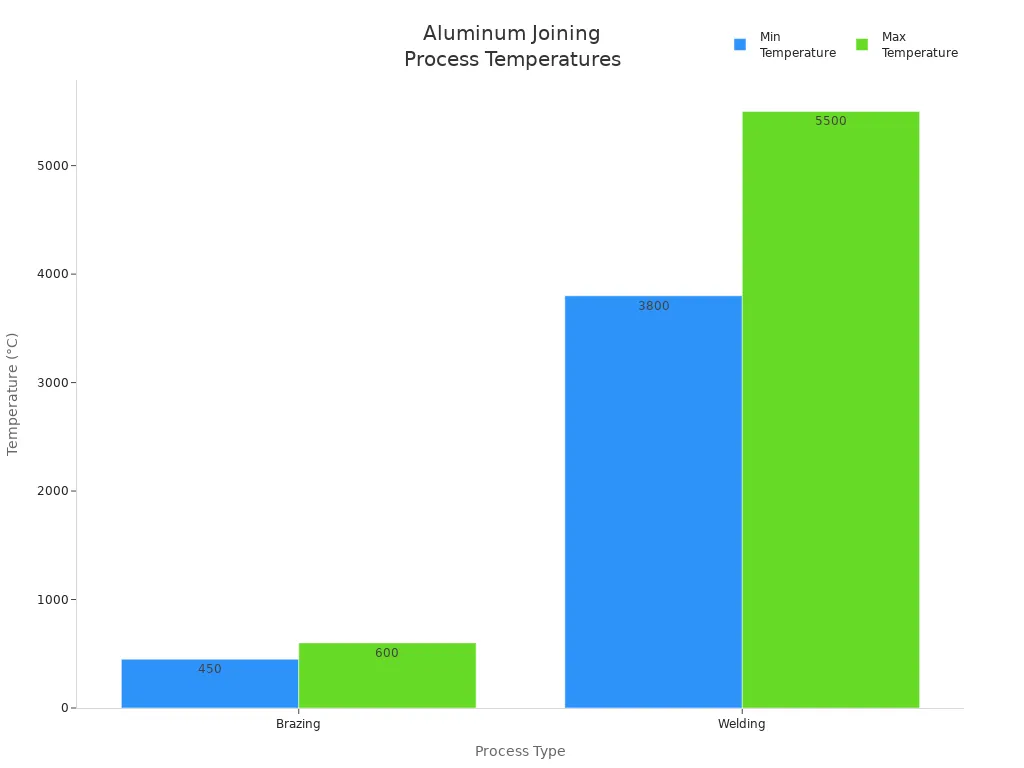

You can join metal with brazing or welding. Brazing heats aluminum but does not melt it. The filler metal melts and goes between the pieces. Welding uses much hotter heat. It melts the base metal to stick parts together forever. The table below shows how hot each process gets:

| Process | Temperature Range | Key Characteristic |

|---|---|---|

| Brazing | 450°C to 600°C (840°F to 1112°F) | Heats base metal below melting point; filler metal melts |

| Welding | Up to ~3800°C to 5500°C (6872°F to 9940°F) | Melts base metal to fuse components |

Brazing needs less energy. Lower heat keeps the base metal strong. It also lowers the chance of bending or warping.

Distortion Risk

Distortion means a part can change shape during joining. Welding causes more distortion because it uses high heat. The base metal melts and cools fast, which can bend thin parts. Brazing keeps the base metal solid. It spreads heat evenly, so parts do not warp as much. This makes brazing good for thin or delicate aluminum parts.

Metallurgical Bond

Brazing joins metal by melting a filler metal between the pieces. The base metal stays solid. This keeps the aluminum’s original strength. The bond spreads stress out, so it helps stop cracks from forming. Brazed joints also block air and water, which helps stop rust. Welding melts the base metals together to make a strong bond. This can make the joint as strong as the metal itself. But welding creates a heat zone that can change the metal’s structure. This can lower strength and make rust or warping more likely.

- Brazing uses less heat, so it avoids warping and keeps the metal strong.

- The process gives better shape and a smooth joint.

- Welding is best for heavy loads but can cause bending and stress.

Application Range

Brazing and welding work for different jobs. Brazing is good for joining thin or delicate metal parts. It also works for joining different kinds of metals. You see brazing in heat exchangers, radiators, and fuel lines. Welding is better for thick, strong aluminum parts. It is used in frames, engines, and car bodies.

| Aspect | Brazing (Aluminum) | Welding (Aluminum) |

|---|---|---|

| Suitable Metals | Aluminum and alloys, joins dissimilar metals | Aluminum and alloys, best for same metals |

| Component Geometry | Thin, intricate, or delicate parts | Thick, load-bearing parts |

| Application Examples | Heat exchangers, radiators, fuel lines | Frames, engine parts, vehicle chassis |

| Thermal Effect | Less thermal distortion, base metal stays solid | More thermal distortion, base metal melts |

| Joining Capability | Joins dissimilar metals well | Best for similar metals |

Brazing lets manufacturers join aluminum and other metals with less risk of bending. Welding makes a strong bond for tough jobs but needs more skill and can change the metal more.

Advantages of Brazing

Lower Temperature

Manufacturers like brazing because it uses less heat than welding. The lower heat keeps the aluminum solid and stops it from melting. This helps protect parts that can be damaged by heat. The filler metal melts and moves between the pieces to join them. The base metal does not change its structure. Brazing usually happens between 450°C and 600°C. This is not hot enough to melt aluminum. These temperatures help the metal stay strong and flexible. Using less heat also means there is less stress and bending. DAG’s aluminum brazing furnace controls the heat very well. This keeps thin or fragile parts safe.

Dimensional Stability

Brazing helps parts keep their shape better than welding. The filler metal flows easily and fills the joints well. This makes sure there are fewer gaps. The filler melts at a low temperature, so there is less shrinking when it cools. This helps stop bending and cracks. Manufacturers use brazing for parts that need to be exact, like car engines and electronics. The process keeps the size and shape of the parts the same. DAG’s aluminum brazing furnace gives even heat and cools parts slowly. This helps make strong joints with little change in shape.

| Property/Advantage | Explanation |

|---|---|

| Low melting point (~577°C) | Lets brazing happen at lower heat, so there is less bending |

| Low shrinkage | Stops bending and cracks, keeps parts the right shape |

| Excellent fluidity | Fills joints well, so there are fewer gaps |

| Dimensional stability | Good for parts that must stay the same size |

| High silicon content | Makes parts last longer and helps stop cracks from heat |

Cost Efficiency

Brazing saves money when making lots of parts. It is easier to learn and can be done by machines. Manufacturers can use batch processing to make more parts at once. Less skill is needed, so labor costs are lower. Brazing tools cost less and are easier to fix. DAG’s aluminum brazing furnace uses less energy and is simple to use. This lowers the cost to run it. The lower heat also means less energy is used. Manufacturers spend less on repairs and finishing because brazing causes less bending.

- Brazing is easy to use with machines, so it works well for big jobs.

- It uses less energy, so it costs less to run.

- Tools and workers cost less than with welding.

| Cost Factor | Brazing | Welding |

|---|---|---|

| Equipment Cost | Cheaper tools | Special tools cost more |

| Labor Skill Requirement | Easy to learn, less skill needed | Needs more skill |

| Production Speed | Makes many parts at once | Joins one spot at a time |

| Automation Suitability | Easy to use with machines | Harder to use with machines |

| Distortion & Finishing | Less heat, less work after joining | More heat, more work after joining |

| Application Suitability | Good for thin or different metals | Best for strong, heavy parts |

Tip: Manufacturers who pick brazing for aluminum parts save money, work faster, and get good quality. DAG’s aluminum brazing furnace helps with these things by giving good control and working well.

Stress Distribution

Stress distribution is very important when joining metal. Brazing makes joints that spread stress over the whole area. The process uses a filler metal that moves into the space between parts. The filler sticks to the surfaces but does not melt the base metal. This makes the joint share force more evenly.

Welding makes a small area that gets very hot. This spot can be weak. Stress can build up here and cause cracks later. Brazing does not have this problem. The joint stays strong because the base metal does not melt. The filler metal makes a smooth link between parts. This link helps the joint stand up to shaking and hits.

DAG’s aluminum brazing furnace helps by keeping the heat just right. The furnace keeps the temperature steady. This helps the filler metal move well and fill all spaces. The joint has no empty spots or weak places. Manufacturers use brazing for parts that get stressed a lot, like radiators and heat exchangers. These parts need to last long and work under pressure.

Note: A big reason to use brazing is that it makes joints that handle stress well. This is why brazing is picked for exact parts in many fields.

Brazing is also good for joining different metals. The process spreads stress even if the metals grow or shrink at different rates. This helps stop problems in tough jobs.

| Joining Method | Stress Distribution | Risk of Cracking | Suitability for Precision Parts |

|---|---|---|---|

| Brazing | Even | Low | High |

| Welding | Uneven | Higher | Lower |

Brazing helps manufacturers trust the strength and safety of their products. The process gives great results, especially with tools like DAG’s aluminum brazing furnace.

Aluminum Brazing Furnace Solutions

DAG Product Overview

DAG makes different aluminum brazing furnace models for factories. These furnaces help make radiators, intercoolers, and heat exchangers. Each model has good controls and gives steady results. DAG designs the equipment to be easy and safe to use. Operators can run the furnace with simple buttons. The company can change furnace sizes for different products. This helps factories make many kinds of parts. DAG builds every furnace to follow industry rules. The equipment helps cut down on waste and saves resources. Factories use less energy and help the environment.

- Good temperature controls give even brazing results.

- Easy controls and safety features make work smooth.

- Different sizes fit many product needs.

- Following rules means safe and steady work.

- Smart design cuts waste and saves energy.

Continuous Brazing

Continuous brazing joins aluminum parts in a special air. DAG’s continuous furnace has heating and cooling zones you can change. A mesh belt moves parts through each step. This setup lets factories make lots of parts with the same quality. The furnace uses nitrogen to stop oxidation. Factories can make many parts fast and get the same results each time. Machines like core builders and flux sprayers help work go faster. These tools help keep joints even and parts put together right.

Experts say continuous brazing has many good points. Better furnace design and air control make quality higher. Factories can make more parts and follow rules better. Systems from companies like Chalco help keep quality steady and save time. These changes help parts work better and make building easier.

Vacuum Brazing

Vacuum brazing is good for special or tough parts. DAG’s vacuum furnace keeps out oxygen. Automatic controls keep the heat just right. This stops oxidation and makes strong, tight joints. Factories use vacuum brazing for tricky parts and different metals. The process keeps heat steady and joints strong, even under stress. Parts do not bend much, so they stay the right shape. Filler metals that melt at low heat protect the main part from damage.

| Advantage | Explanation and Benefit |

|---|---|

| No oxidation in joints | No oxygen means joints stay clean and strong. |

| Precise and steady results | Careful controls make joints right for hard jobs. |

| Stays strong with heat | Joints keep their strength when things get hot. |

| Very strong and tough | Joints last a long time in hard jobs. |

| Little bending | Careful heat keeps parts from changing shape. |

| Joins tricky shapes | Can join many shapes and different materials. |

| Uses low-heat filler metals | Less heat keeps main parts safe. |

| Good for sensitive industries | Works well for planes, robots, and medical tools. |

Vacuum brazing needs careful control of heat and timing. Preheating and low-heat filler metals help lower stress from heat. Careful planning keeps parts strong and working well for tough jobs.

Carrier Gas Brazing

Carrier gas brazing is a way to join aluminum parts. This method uses both vacuum and carrier gas heating. DAG makes carrier gas brazing furnaces for plate-fin heat exchangers and other hard products. These furnaces help factories make joints that are strong and clean.

First, the furnace pulls out air to make a vacuum. This step gets rid of air and water in the chamber. Next, a carrier gas like nitrogen or argon goes in. The carrier gas keeps the metal safe from oxidation when it gets hot. The furnace then heats the parts to the right temperature. The filler metal melts and moves between the aluminum pieces. The carrier gas keeps the area clean and steady.

DAG’s carrier gas brazing furnaces have many good features:

- Vacuum and carrier gas system: The furnace takes out air and uses a special gas to keep parts clean.

- Precise temperature control: The system heats parts evenly. This helps the filler metal move and fill all spaces.

- Customizable chamber size: Factories can pick the size that fits their products.

- User-friendly controls: Workers can set and watch the process with easy buttons.

- Energy efficiency: The furnace saves energy and helps lower costs.

Note: Carrier gas brazing is great for plate-fin heat exchangers. These need joints that are clean and strong. This method also works well for parts with tricky shapes.

The table below shows how carrier gas brazing is different from other ways:

| Feature | Carrier Gas Brazing | Continuous Brazing | Vacuum Brazing |

|---|---|---|---|

| Atmosphere | Vacuum + Carrier Gas | Nitrogen | High Vacuum |

| Cleanliness | High | Medium | Very High |

| Suitable Products | Plate-fin heat exchangers | Radiators, condensers | Complex, sensitive parts |

| Energy Use | Efficient | Efficient | Moderate |

| Joint Strength | Strong | Strong | Very Strong |

Factories use carrier gas brazing for products that must be strong and clean. The process helps make heat exchangers for cars and machines. It also helps make parts with lots of fins or layers.

DAG’s carrier gas brazing furnaces help factories meet tough quality rules. The system keeps joints safe from oxidation and problems. This makes products that last longer and work better.

Tip: Carrier gas brazing lets factories control the joining process better. This helps them make good products and waste less.

Brazing Over Welding in Industry

Automotive Applications

Car makers use brazing instead of welding for many parts. Brazing helps make joints that do not leak. It joins thin aluminum tubes and fins in radiators and heater cores. Brazing also works for air conditioning parts. Welding can hurt delicate materials, but brazing does not. Brazing connects fuel lines, brake lines, brackets, and sensor housings. These parts need to be strong and not leak.

- Radiators and heater cores

- Air conditioning condensers and evaporators

- Fuel and brake lines

- Small brackets and sensor housings

Brazing helps factories make lots of parts fast. Machines use flux-cored and flux-coated products to help the process. This makes the flow better and lowers mistakes. Factories can make more parts with less fixing. Brazing joins different metals, which welding cannot do easily. Manufacturers pick brazing to protect sensitive materials and keep work quick.

In car factories, brazing makes smooth, sealed joints in fuel systems, exhaust systems, and heat exchangers. These jobs need less heat, so parts stay strong and safe from damage.

Heat Exchanger Manufacturing

Heat exchanger makers use brazing to build small, strong products. Brazing lets them join thin plates and tubes without melting the base metal. This makes joints that are strong and do not leak. Aluminum brazing sheets have a core alloy and a filler layer that melts at low heat. This helps join parts without welding and keeps the shape safe.

- Small size saves space and makes it easy to install

- High thermal efficiency uses less energy

- Brazed joints mean no gaskets, so less fixing is needed

- Light weight makes moving and handling easier

- Fewer connections mean fewer leaks

Brazing helps control heat better. It also stops rust and helps heat move through the metal. Factories use brazing to make car cooling modules, boat coolers, and industrial heat recovery devices. The process helps companies meet tough quality rules and make good products.

Aerospace and Defense

Aerospace and defense companies use brazing instead of welding for important systems. Brazing makes joints that are strong and do not let heat or rust in. These joints keep fuel, hydraulic, and oxygen lines safe from leaks and shaking. Sometimes, mechanical joining is used to avoid heat damage, but brazing is still the best for many parts.

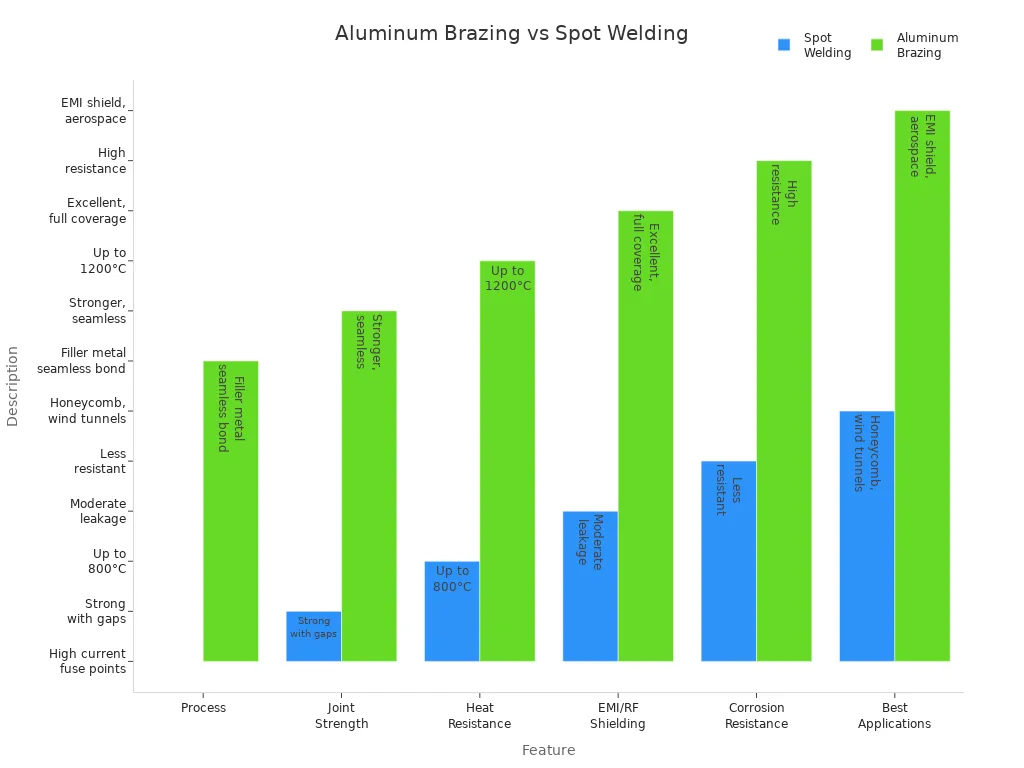

| Feature | Spot Welding | Aluminum Brazing |

|---|---|---|

| Process | Uses high current to fuse metal points | Uses filler metal to create a continuous, seamless bond |

| Joint Strength | Strong but with weld gaps | Stronger, seamless joints |

| Heat Resistance | Up to 800°C | Up to 1200°C |

| EMI/RF Shielding | Moderate, may allow leakage | Excellent, full coverage |

| Corrosion Resistance | Less resistant due to weld gaps | High resistance |

| Best Applications | General honeycomb structures, wind tunnels | EMI shielding, aerospace, gas turbines |

Brazing gives better joint strength and higher heat resistance. It also gives better shielding. These things matter for planes and defense gear that work in hard places. Brazing helps build complex parts without welding, so heat does not hurt them.

Brazing without welding helps companies meet strict safety and performance needs in aerospace and defense. The process makes joints that last a long time and work well for tough jobs.

Join Metal: Decision Factors

Strength and Reliability

Manufacturers want strong and reliable ways to join metal. Brazing melts a filler metal between two pieces. The base metal stays solid. This helps spread force across the joint. Brazing works for many jobs. Welding is better for heavy-duty needs. Welding melts the base metal. It makes a bond that can hold heavy loads. Frames and supports often use welding. Brazing is strong enough for radiators and heat exchangers. These parts do not face extreme stress. The best way depends on how strong the joint needs to be.

Maintenance Needs

Maintenance is important when picking how to join metal. Brazed joints block leaks and stop rust. The process seals gaps and keeps out water. This helps parts last longer. It also means fewer repairs. Welding makes a strong joint too. But the heat can change the metal. Sometimes this causes weak spots. These spots may need more checks later. For parts that need to last and need little fixing, brazing is often best. Factories want fewer repairs and longer life. They pick brazing or welding based on how much fixing the joint will need.

Cost-Benefit Analysis

Cost is a big factor when joining metal. Brazing uses less heat and simple tools. It is easier to automate and teach workers. Welding needs more skill and special equipment. This can make it cost more. The table below shows key things to think about:

| Factor | Aluminum Brazing | Welding |

|---|---|---|

| Material Compatibility | Works with aluminum and dissimilar metals | Best for metals that can melt, like steel |

| Joint Strength | Moderate, good for many uses | Very strong, best for heavy-duty jobs |

| Precision & Distortion | High precision, low risk of warping | Can warp thin parts, less precise |

| Heat Tolerance | Uses low heat, protects base metal | Needs high heat, can damage sensitive metals |

| Cost | Higher for small runs, lower for mass production | Lower for large, strong projects |

| Skill Level | Easier to learn and automate | Needs skilled workers |

| Environmental & Safety | Needs safety steps, less heat risk | Needs safety steps, more heat risk |

Factories pick brazing for thin or delicate parts. It is also good for heat-sensitive jobs. Welding is better for strong bonds and heavy loads. Companies should look at the part’s use, needed strength, and cost. Brazing gives a reliable joint with less risk of bending and less fixing. This makes it a smart choice for many jobs.

Manufacturers pick aluminum brazing because it works fast and saves money. DAG’s aluminum brazing furnaces help factories make strong joints that meet rules. Brazing makes joints that last in hot and high-pressure places. The process works with many materials and helps make exact parts. Studies show brazing makes joints stronger and last longer, especially for important jobs. Companies can make things quicker and spend less money. Aluminum brazing is the best choice for today’s factories.

FAQ

What is aluminum brazing?

Aluminum brazing joins two metal pieces with a filler metal. The base metal stays solid and does not melt. This process makes a strong and sealed joint. Many companies use it for radiators and heat exchangers.

How does brazing differ from welding?

Brazing uses less heat and keeps the base metal solid. Welding melts the base metal to stick parts together. Brazing is good for thin or delicate parts. Welding works better for tough jobs.

Why do manufacturers prefer DAG’s aluminum brazing furnace?

DAG’s furnace controls temperature very well and saves energy. The system helps factories make lots of parts fast. Workers find the controls simple to use. The furnace helps make strong and steady joints every time.

Can brazing join different metals?

Yes, brazing can join metals that are not the same. The filler metal sticks to both surfaces. This makes brazing great for building complex things.

What industries use aluminum brazing most?

Car, HVAC, and aerospace companies use aluminum brazing a lot. The process helps make radiators, heat exchangers, and fuel lines. Many factories pick brazing because it is quick and works well.

Is brazing safe for sensitive components?

Brazing uses lower heat, so it protects delicate parts. The process lowers the chance of bending or damage. Many companies use brazing for electronics and thin aluminum pieces.

How does DAG’s furnace help reduce costs?

DAG’s furnace uses less energy and works with machines. The system cuts down on labor and fixing costs. Factories can make more parts with fewer mistakes.

What maintenance does an aluminum brazing furnace need?

Workers should check the temperature controls and clean the furnace often. They should look at conveyor belts and safety systems. Regular checks help stop problems and keep work running smoothly.

Tip: Keeping the furnace clean and checking it often saves money and helps it work well for a long time.