Vacuum brazing furnaces deliver high-quality, oxide-free joints essential for industries such as automotive and aerospace. Manufacturers value the vacuum brazing furnace for its clean process, uniform temperature control, and ability to join dissimilar metals. However, a brazing furnace demands significant investment and technical expertise. In 2025, the global vacuum brazing furnace market continues to grow, driven by automation and increased demand in sectors like electric vehicles. Solutions such as DAG’s Giant Vacuum Aluminum Brazing Furnace set new standards for precision and efficiency.

Key Takeaways

- Vacuum brazing furnaces create strong, clean, and reliable metal joints by preventing oxidation and contamination during the joining process.

- This method joins dissimilar and sensitive metals effectively, expanding design options for complex assemblies in industries like aerospace and electronics.

- Uniform heating and precise temperature control reduce distortion and stress, ensuring high-quality, consistent results across production batches.

- Vacuum brazing eliminates the need for flux, resulting in cleaner parts without residue and reducing extra cleaning steps after brazing.

- Automation and batch processing improve production efficiency, lower labor costs, and maintain consistent joint quality in large-scale manufacturing.

- High initial investment and facility requirements demand careful cost-benefit analysis and skilled operators to maintain vacuum integrity and process control.

- Material selection and joint design are critical to avoid outgassing and ensure strong, corrosion-resistant joints with minimal defects.

- Vacuum brazing suits industries needing precise, high-integrity joints, such as automotive, aerospace, medical devices, and electronics, supporting future manufacturing trends.

Vacuum Brazing Furnace Advantages

Joint Quality

Strength & Reliability

A vacuum brazing furnace delivers exceptional strength and reliability in metal joints. The vacuum environment prevents oxidation, which allows the filler metal to bond directly with the base materials. This process creates joints that often match or exceed the strength of the original metals. The controlled vacuum, typically between 10⁻³ Pa and 10⁻⁵ Pa, reduces the risk of pores and cracks, ensuring dense and mechanically robust connections. Industries such as aerospace and automotive rely on this joining technology for critical components, where consistent joining quality and long service life are essential. The Giant Vacuum Aluminum Brazing Furnace by DAG maintains these high standards through precise vacuum control and advanced heating systems.

- The vacuum brazing furnace ensures high reliability by:

- Preventing oxidation of metal surfaces, especially aluminum.

- Minimizing residual gases, which reduces pore and crack formation.

- Optimizing solder flow for uniform filler metal distribution.

- Delivering strong, sealed, and corrosion-resistant joints.

Minimal Defects

Vacuum brazing minimizes defects that often occur in other joining methods. The absence of air in the furnace eliminates oxidation and contamination, resulting in clean, strong joints. Precise temperature control ensures uniform heating, which avoids overheating and flux entrapment. Batch processing in a vacuum brazing furnace guarantees repeatable results, reducing waste and the need for rework. This process supports high-volume production while maintaining consistent quality across all parts.

- Key benefits include:

- Uniform heating and metallurgical properties.

- Consistent joint quality across production batches.

- Reduced thermal stress and distortion.

- Automation and cycle programming for efficiency.

Material Compatibility

Dissimilar Metals

Vacuum brazing excels at joining metal components made from dissimilar materials. The process allows for the combination of metals that would be difficult or impossible to join using traditional welding. For example, the Giant Vacuum Aluminum Brazing Furnace can join aluminum to copper or stainless steel, which expands design possibilities in heat exchangers and electronic cooling systems. This compatibility supports innovation in industries that require complex assemblies.

Sensitive Alloys

Many advanced alloys, such as titanium aluminides and austenitic stainless steels, require careful handling during joining. Vacuum brazing provides a controlled environment that protects sensitive alloys from oxidation and thermal damage. Scientific studies confirm that vacuum brazing furnaces work well with nickel-based, manganese-based, and titanium-based filler metals, producing strong, durable joints. This capability makes vacuum brazing a preferred method for high-performance applications.

Distortion & Stress

Uniform Heating

Uniform heating is a hallmark of the vacuum brazing process. The furnace uses multiple heating zones and carefully designed elements to keep temperatures consistent throughout the chamber. Temperature uniformity is typically maintained within ±3°C of the set point. Soaking the components just below the filler metal’s melting point ensures that all parts reach the same temperature before brazing begins. This approach prevents localized overheating and reduces the risk of deformation.

- Features that support uniform heating:

- Multiple heating control zones.

- Heating elements designed to match part temperatures.

- Stable vacuum maintained by advanced pumping systems.

Precision

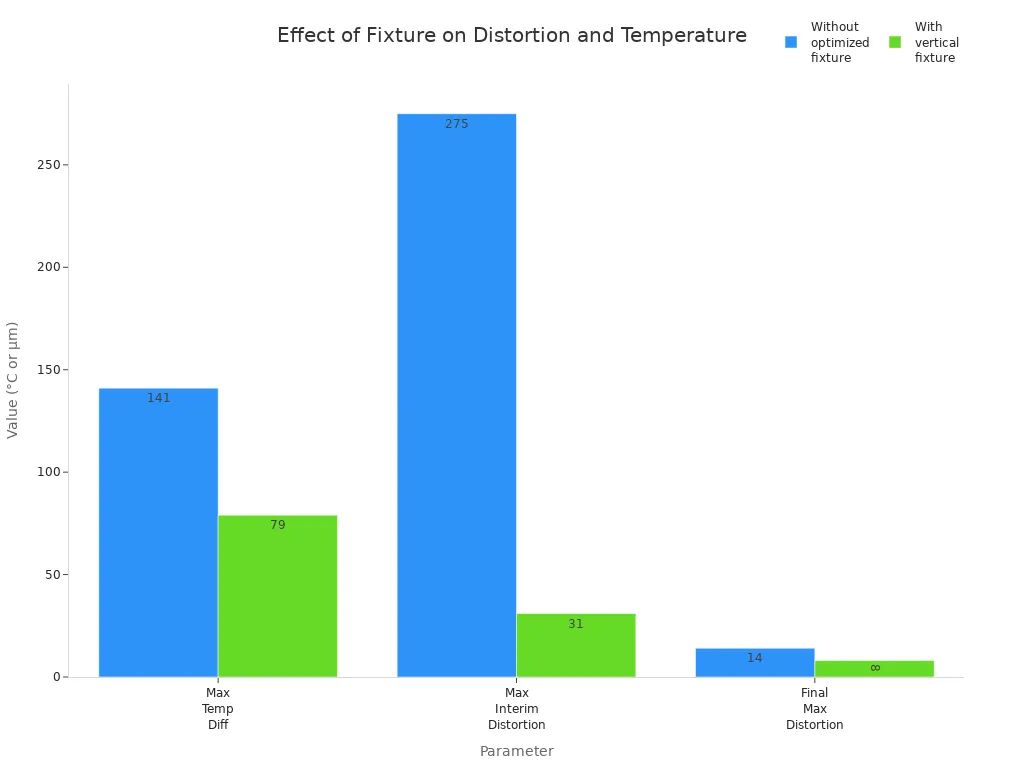

Precision in temperature control and thermal management minimizes distortion and residual stress in joined components. The vacuum brazing furnace controls heating and cooling cycles to keep deformation within the elastic range. Simulation-guided fixture design and controlled cooling further reduce temperature gradients and distortion. Comparative data show that optimized fixturing and controlled cooling can significantly lower both interim and final distortion in brazed parts.

The chart above demonstrates how optimized fixtures and controlled cooling in a vacuum brazing furnace reduce both temperature differences and distortion, ensuring precise and reliable results.

Clean Process

No Flux Residue

Vacuum brazing creates a cleaner process compared to flux-based methods. The furnace operates in a controlled, oxygen-free environment, which prevents oxidation and contamination of metal parts. This setup removes the need for flux, a chemical used in traditional brazing to clean metal surfaces. Without flux, there are no residues left on the finished parts, so manufacturers avoid extra cleaning steps after brazing.

- Vacuum brazing eliminates flux and its residues, preventing flux entrapment.

- The process avoids messy parts and reduces the risk of joint failure.

- Uniform heating and atmosphere control result in cleaner, more reliable joints.

Traditional torch brazing often leaves corrosive flux residues that require soaking or quenching to remove. Vacuum brazing, by contrast, skips these steps, saving time and reducing the risk of contamination.

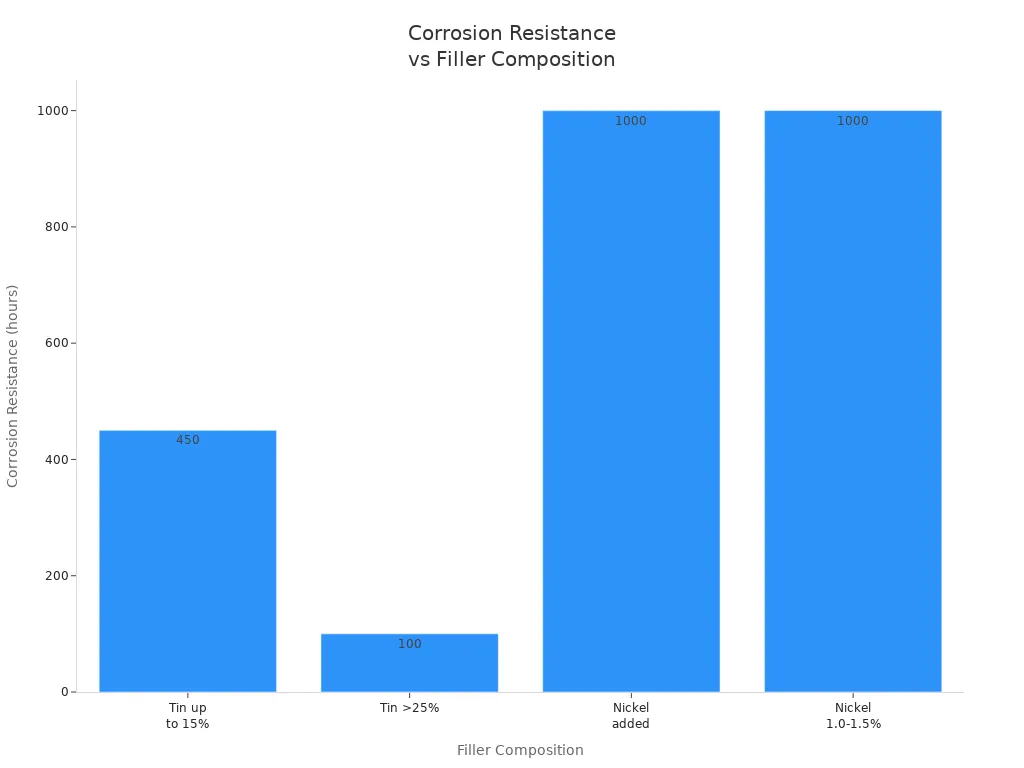

Corrosion Resistance

Vacuum brazing improves corrosion resistance in metal joints. The furnace uses nickel-based filler metals and precise temperature control to avoid the formation of brittle phases and voids that can weaken joints. Research shows that optimizing the microstructure during brazing increases both fatigue performance and resistance to corrosion fatigue, even under mechanical and corrosive stress.

Surface microstructuring, such as laser texturing and electroplating, further strengthens joints. These techniques increase shear strength and prevent crack growth, which helps the joint resist corrosion in harsh environments.

| Filler Composition Element | Effect on Shear Strength | Effect on Corrosion Resistance |

|---|---|---|

| Increasing Tin Content (up to 15%) | Slight decrease in strength; strength stable below 25% tin | Corrosion resistance increases, peaking at 15% tin (~450h corrosion time) |

| Tin Content > 25% | Strength decreases significantly due to brittle phase formation | Corrosion resistance decreases sharply |

| Addition of Small Amount of Nickel (to Ag-Cu-Sn) | Shear strength increases from 8 MPa to ~30 MPa | Corrosion resistance greatly improved; joints withstand >1000h in 5% NaCl at 80°C without failure |

| Nickel Content 1.0% – 1.5% | Maintains high strength after corrosion | Enhanced corrosion resistance |

The addition of nickel to the filler metal improves both strength and corrosion resistance, while optimal tin content balances these properties.

Environmental Benefits

Low Emissions

Vacuum brazing furnaces support sustainable manufacturing by reducing emissions. The furnace uses electricity instead of combustion, so it does not produce waste gases or liquids. The vacuum environment prevents oxidation and contamination, which means cleaner joints and no release of pollutants. Multi-layer insulation and precise temperature control also help the furnace save energy, lowering the carbon footprint of the production process.

Vacuum brazing reduces material waste and energy consumption. This efficiency helps companies meet strict environmental regulations and supports global efforts to reduce industrial emissions.

Safety

Vacuum brazing furnaces improve workplace safety. The controlled atmosphere inside the furnace reduces employee exposure to harmful fumes and particles. The enclosed design prevents toxic materials from escaping into the workspace, which keeps air quality high. Programmable temperature control and real-time monitoring lower the risk of thermal shock and accidents.

- The system reduces fire hazards and respiratory incidents by up to 40%.

- Companies see lower insurance costs and a more stable workforce.

- Compliance with safety standards, such as OSHA, is easier to achieve.

Process Efficiency

Batch Production

Vacuum brazing furnaces operate in tightly controlled batch cycles. Advanced controllers manage temperature, vacuum, and process sequences with high precision. These systems allow manufacturers to set up and run multiple temperature profiles and recipes, which increases throughput and reduces errors. The furnace design, with features like internal gas blowers and heat exchangers, improves temperature uniformity and shortens cycle times.

Batch processing in a vacuum furnace ensures consistent quality across large production runs. The system minimizes distortion and eliminates the need for extra machining, which saves time and resources.

Automation

Automation in vacuum brazing furnaces increases production efficiency and consistency. Automated systems control temperature and pressure with high accuracy, which improves the quality of each brazed joint. Real-time monitoring and data analysis help optimize the process and reduce downtime.

- Automation reduces human intervention, lowering labor costs.

- The system delivers faster production speeds and fewer errors.

- Consistent product quality becomes easier to achieve, even in large-scale operations.

Skilled technicians still play a role in oversight, but automation allows companies to maintain high standards with less manual effort.

Vacuum Brazing Limitations

Investment Cost

Equipment Price

A vacuum brazing furnace represents a significant capital investment for any manufacturing operation. The advanced technology, precision engineering, and robust construction drive up the initial purchase price. For example, high-capacity models with customizable features can range from several hundred thousand to several million RMB. These costs reflect the need for specialized materials, high-performance heating elements, and sophisticated vacuum systems. Companies must evaluate their production volume and long-term needs before committing to such an investment.

Facility Needs

Operating a vacuum brazing furnace requires more than just floor space. Facilities must meet strict requirements to ensure reliable and safe operation. Key considerations include:

- Clean parts and fixtures before loading to prevent contamination.

- Proper part placement and secure loading techniques to avoid movement or damage during brazing.

- High-quality backfill gas and piping systems to maintain vacuum integrity.

- Regular maintenance of seals, especially door O-rings, with cleaning and vacuum grease application to prevent leaks.

- Frequent leak detection and repair, often using helium leak detectors, to ensure a leak-free environment.

- Maintenance of vacuum pumps, hot zones, power feed-throughs, and cooling systems to sustain performance.

- Implementation of safety protocols, such as confined space entry and electrical lockout procedures, during maintenance.

- A planned preventative maintenance program, including daily, weekly, and periodic inspections, to extend furnace life.

- Supplier support infrastructure, including 24/7 technical support, remote diagnostics, spare parts, field service, and training.

These requirements add to the overall costs and complexity of setting up and running a vacuum brazing operation.

Process Constraints

Size & Geometry

Vacuum brazing imposes certain constraints on the size and geometry of parts that can be processed. The internal dimensions of the furnace limit the maximum size of components. Part orientation and placement inside the chamber also affect heating uniformity and cooling rates. Complex geometries, thin sections, or parts with internal features like cooling channels may experience distortion due to thermal gradients and residual stresses. Joint gap width is another critical factor; gaps typically must remain below 50–70 micrometers to avoid the formation of brittle intermetallic phases that weaken the joint. Simulation tools help engineers predict distortion, optimize part positioning, and plan temperature cycles to reduce these risks.

- Thin or varying material thicknesses can increase stress during cooling, leading to cracks or failures.

- Unknown pretreatment or residual stress states in supplied components can affect brazing outcomes.

- The choice between vacuum and convective cooling methods impacts distortion and limits part size.

Joint Design

Joint design plays a vital role in the success of vacuum brazing. The process excels at joining complex geometries and precision assemblies. The vacuum environment promotes wetting and capillary flow of the braze alloy into intricate joints, eliminating oxides and unwanted reactions. This results in clean, high-quality joints without the need for post-processing. Vacuum brazing works well for applications requiring tight tolerances and complex designs, such as aerospace, medical, and semiconductor industries. The process imposes virtually no limit on wall thickness for complex geometries, unlike welding, which can cause distortion or require extra machining. Lower temperatures used in brazing preserve base metal properties and reduce thermal stress, making it suitable for strength-to-weight optimization and hermetic seals in electronics.

Material Limits

Outgassing Issues

Material selection is critical in vacuum brazing due to the risk of outgassing. During heating, materials inside the furnace release trapped gases such as water vapor, hydrogen, carbon dioxide, and hydrocarbons. This release raises chamber pressure, reduces vacuum quality, and can introduce contaminants that degrade joint quality. Outgassing also strains vacuum pumps and may lead to oxidation or discoloration of parts. To mitigate these issues, manufacturers should:

- Pre-bake materials outside the furnace to remove volatiles.

- Select low-outgassing materials, such as certain metals and ceramics.

- Bake the vacuum system under vacuum to accelerate gas release before brazing.

- Use cold traps to capture volatile gases before they reach the pump.

- Thoroughly clean and degrease workpieces before furnace entry.

- Avoid fluxes and filler metals with high vapor pressures.

- Purge thermal barriers with nitrogen to prevent air or moisture outgassing.

Maintaining cleanliness and proper material selection ensures stable vacuum conditions and high-quality brazing results.

Filler Metal

Not all filler metals are suitable for vacuum brazing. Alloys must meet strict purity standards to prevent outgassing and maintain vacuum integrity. Elements such as cadmium, zinc, manganese, and phosphorus are problematic due to their volatility. These elements can evaporate at brazing temperatures, causing contamination and compromising joint strength. The American Welding Society defines vacuum-grade filler metals with precise chemical composition requirements. Recommended alloys for vacuum use include silver-copper eutectics, copper-silver-tin, and copper-silver-phosphorus alloys, which minimize outgassing and ensure strong, corrosion-resistant joints. Manufacturers must avoid using materials and coatings that contain high vapor pressure elements or plastics prone to outgassing, such as Kapton or Teflon.

Cycle Time

Heating & Cooling

Vacuum brazing requires precise control of heating and cooling rates. Operators set the initial heating rate below 15°C per minute to prevent defects such as spalling or distortion. After this stage, the furnace can increase the ramp rate to 15°C–25°C per minute until reaching the brazing temperature. This careful approach protects the base metal and ensures the filler alloy melts at the right moment. Unlike traditional welding, which often uses less controlled heating, vacuum brazing maintains a uniform temperature throughout the chamber. This uniformity reduces the risk of thermal gradients and preserves the integrity of both the joint and the parent material.

Cooling in vacuum brazing also follows a controlled schedule. Slow cooling can increase the risk of unwanted phase formation, such as sigma phase in duplex stainless steels. Faster cooling rates help suppress these phases, improving joint quality. The ability to adjust cooling rates allows manufacturers to optimize the process for different materials and applications. However, these controlled cycles extend the total process time compared to some rapid joining methods.

Vacuum brazing cycle times typically range from 3 to 24 hours, depending on the material, part complexity, and desired properties. Simpler assemblies may require less time, while complex or large parts extend the cycle. This variability means production planners must schedule batches carefully to maximize throughput and avoid bottlenecks.

Production Speed

Production speed in vacuum brazing depends on the length of each cycle and the size of the batch. The vacuum environment enables faster heating and cooling than some traditional methods, reducing cycle times by up to 20%. This improvement increases throughput and allows manufacturers to complete orders more quickly. Proper material preparation and regular furnace maintenance further optimize production speed by minimizing defects and rework.

Despite these advantages, vacuum brazing remains a batch process. Each cycle must complete before operators can unload and reload the furnace. This requirement can limit flexibility for urgent or small-volume orders. Manufacturers must balance the need for high-quality joints with the realities of production scheduling. Careful planning ensures that the benefits of vacuum brazing—such as superior joint quality and consistency—outweigh the longer cycle times.

Design Complexity

Fixturing

Successful vacuum brazing relies on precise fixturing. Fixtures hold parts in perfect alignment and minimize gaps during the brazing process. Proper fixturing ensures that the filler metal flows by capillary action and forms strong, uniform joints. Engineers design fixtures to withstand high temperatures and maintain their shape throughout the cycle. They also select materials that do not react with the parts or the furnace atmosphere.

Cleaning and preparation play a critical role. Operators must remove oxides and contaminants from all surfaces before assembly. Chemical or abrasive cleaning methods create the right surface roughness for the filler metal to wet the base metal. In aluminum brazing, additives such as magnesium act as getters, removing oxygen and water vapor to improve joint adhesion.

The table below summarizes key aspects of design complexity in vacuum brazing:

| Design Complexity Aspect | Description |

|---|---|

| Fixturing | Holds parts in alignment and minimizes gaps for proper joint formation. |

| Cleaning & Preparation | Ensures oxide-free, clean surfaces for capillary action. |

| Additives | Improves furnace environment and joint adhesion. |

| Operator Expertise | Maintains quality through precise process control. |

| Environmental Control | Monitors atmosphere to prevent contamination. |

| Documentation | Guides operators with detailed process steps. |

Expertise

Vacuum brazing requires skilled operators and engineers. They must understand the principles of vacuum technology, furnace operation, and process control. Operators follow detailed procedures for cleaning, assembly, and monitoring environmental factors such as gas dew point. They calibrate and maintain furnace recording systems to ensure compliance with temperature requirements.

Specialized expertise extends to programming PLCs, integrating robots, and managing automated control systems. Companies invest in regular training to keep staff proficient in all aspects of the process. This expertise supports innovation, process optimization, and compliance with industry standards.

The need for skilled personnel can increase operational costs. Smaller manufacturers may find it challenging to build or maintain the necessary expertise. However, companies that invest in training and collaboration with research institutions gain a competitive advantage. They can adopt advanced automation, improve process reliability, and develop new applications for vacuum brazing.

Skilled operators and engineers ensure that vacuum brazing delivers consistent, high-quality results. Their expertise supports process innovation and long-term success in demanding industries.

Comparison Table: Pros vs. Cons

Vacuum brazing furnaces play a key role in modern metal joining. They offer unique strengths and present specific challenges. The following table summarizes the most important pros and cons based on recent industry data:

| Aspect | Pros | Cons |

|---|---|---|

| Joint Cleanliness | Removes air and gases, resulting in clean, rust-free parts | Batch process slows production due to vacuum cycling |

| Material Compatibility | Joins special metals and alloys, including dissimilar materials | High purchase and maintenance costs |

| Process Control | Adjustable heat and pressure for each batch | Requires skilled workers for vacuum system upkeep |

| Flexibility | Handles different sizes and shapes | Higher energy use per part compared to continuous furnaces |

| Product Quality | Produces strong, pure joints without extra chemicals | Batch furnaces best for small to medium batch sizes |

| Vacuum Integrity | Maintains clean vacuum, prevents oxidation | Higher initial investment and system complexity |

| Energy Efficiency | Continuous operation reduces energy use | Needs regular maintenance to ensure vacuum integrity |

| Labor Costs | Automation reduces labor and errors | System complexity demands skilled maintenance |

| Throughput | Steady, high-quality output for high production volumes | Higher upfront cost compared to batch vacuum furnaces |

| Scalability | Suitable for medium to high production volumes | Limited by furnace size and longer cycle times |

Note: Vacuum brazing furnaces deliver clean, strong joints for aerospace, medical, and electronics applications. However, they require careful planning and skilled operation.

Vacuum brazing furnaces stand out for their ability to produce joints free from oxidation and contamination. This advantage makes them the preferred choice for joining metals with stable oxides or for applications that demand high purity. The controlled environment inside the furnace allows precise adjustment of heat and pressure, which leads to consistent results across batches.

Manufacturers benefit from the flexibility to process different shapes and sizes. Automation further reduces labor costs and errors. The system maintains a clean vacuum, which prevents oxidation and ensures joint strength.

However, these benefits come with trade-offs. The initial investment for a vacuum brazing furnace is high. Maintenance costs also add up over time. Skilled technicians must monitor and maintain the vacuum system to prevent leaks and ensure reliable operation. Batch processing limits throughput, especially for very large-scale production. The process also uses more energy per part than some continuous furnaces.

Scalability remains a challenge. Furnace size and cycle time restrict the number of parts processed at once. For companies with high-volume needs, continuous atmosphere furnaces may offer better scalability, though they may not match the joint quality of vacuum brazing.

Practical Considerations 2025

Application Fit

Manufacturers in 2025 must evaluate whether vacuum brazing matches their production needs. This process works best for industries that demand high-quality, precise, and reliable joints. Companies in automotive, aerospace, electronics, and medical device sectors often select this method for its ability to join complex assemblies and dissimilar metals. The technology also supports new applications in additive manufacturing and advanced electronics packaging.

Key applications and industries include:

- Heat exchangers for automotive and industrial use

- Aircraft components requiring lightweight and strong joints

- Medical devices that need precise, clean assembly

- Electronic assemblies and advanced packaging

- Defense systems with strict reliability standards

- Renewable energy systems, such as solar and wind components

The table below summarizes the market position and trends for each industry:

| Industry/Application | Market Position & Trends | Key Drivers & Notes |

|---|---|---|

| Automotive | Largest segment (~40% revenue share) | Focus on lightweight, fuel-efficient vehicles, automation growth |

| Electronics | Significant segment (~30% revenue share) | High-precision needs, advanced packaging |

| Aerospace | Growing segment | Stringent quality, custom furnace demand |

| Medical Devices | Growing segment | High precision, emerging applications |

| Defense | Key application | Reliable, high-quality joints |

| Renewable Energy | Emerging application | Market growth expected by 2033 |

| Heat Exchangers | Important for energy and industry | Supports energy efficiency |

Companies should match their product requirements with the strengths of vacuum brazing to maximize quality and efficiency.

Cost-Benefit

A thorough cost-benefit analysis helps manufacturers decide if investing in a vacuum brazing furnace is justified. This process allows simultaneous joining of multiple parts, which reduces production time and costs. Simple fixtures can replace expensive specialized equipment, and the short production cycle further improves efficiency. The process produces smooth, dense seams that enhance mechanical and thermal properties, which can extend product life.

Manufacturers benefit from:

- Reduced rework and scrap due to repeatable, high-quality results

- Compliance with strict industry standards, such as NADCAP

- Ability to join a wide range of metals, including those that are hard to weld

- Minimal distortion, which maintains tight tolerances and reduces post-processing

Companies must weigh these advantages against the initial investment and ongoing operational costs. For many, the long-term savings and product improvements outweigh the upfront expense.

Industry Trends

In 2025, several trends shape the adoption of vacuum brazing. Automation and digitalization continue to expand, allowing for better process control and data tracking. Energy efficiency remains a top priority, with manufacturers seeking furnaces that use less power and produce less waste. The use of advanced materials, such as composites and high-performance alloys, drives demand for precise joining methods.

Regional growth remains strong in East Asia, North America, and Europe. The market expects a compound annual growth rate of 6-7% through 2030. Companies that invest in modern brazing technology position themselves to meet future demands for quality, efficiency, and sustainability.

Choosing Vacuum Brazing

Selecting vacuum brazing as a joining method requires careful evaluation of project needs and production goals. Manufacturers often compare vacuum brazing with other joining technologies, such as welding, soldering, or traditional furnace brazing. Each method offers unique strengths, but vacuum brazing stands out in several key scenarios.

Key situations where vacuum brazing is the optimal choice:

- Precise temperature control is necessary to ensure the filler metal melts at the exact point for strong, reliable joints.

- Elimination of oxidation and contamination is critical, as the vacuum environment prevents these issues and strengthens the joint.

- The application demands strong, leak-tight, and flux-free joints, especially for high-integrity products.

- The assembly involves dissimilar metals or complex geometries that challenge other joining methods.

- Minimal distortion is required to preserve tight tolerances, especially for delicate or intricate parts.

- Consistent and repeatable results are essential for mass production or industries with strict quality standards.

- Ultra-clean, high-integrity joints are needed, such as in aerospace, medical, or electronics manufacturing.

- The process must avoid secondary finishing steps, saving both time and resources.

- Welding is difficult or impossible, or the assembly requires precise joining of multiple components.

Tip: Vacuum brazing works best for applications where contamination or oxidation would cause failure, or where joint quality cannot be compromised.

Manufacturers should also consider the resources available. Vacuum brazing requires specialized equipment and skilled operators. Companies with access to advanced furnaces, such as DAG’s Giant Vacuum Aluminum Brazing Furnace, can take full advantage of the process’s benefits. This technology supports joining a wide range of materials, including dissimilar metals, and handles complex, multi-layered assemblies with tight tolerances.

The decision to use vacuum brazing often depends on the following factors:

| Decision Factor | Why It Matters |

|---|---|

| Joint Quality | High-integrity, flux-free, and clean joints |

| Material Compatibility | Ability to join dissimilar or sensitive metals |

| Part Complexity | Success with intricate or multi-layered parts |

| Production Volume | Consistency and repeatability for large batches |

| Facility Resources | Need for specialized equipment and expertise |

When these factors align with project requirements, vacuum brazing becomes the preferred solution. Companies that prioritize joint strength, cleanliness, and reliability often choose this method to meet demanding industry standards and future-proof their manufacturing processes.

Vacuum brazing furnace offer strong, clean joints and support advanced manufacturing needs in 2025. High investment and technical demands remain key challenges. Companies should:

- Match furnace strengths to their product requirements.

- Assess costs and benefits for their industry.

- Consult suppliers like DAG for expert advice.

Tip: Start with a pilot project or technical evaluation to see if vacuum brazing fits your production goals.

FAQ

What industries benefit most from vacuum brazing furnaces?

Automotive, aerospace, electronics, and medical device manufacturers use vacuum brazing furnaces. These industries require strong, clean joints and precise assembly for critical components.

How does vacuum brazing improve joint quality?

Vacuum brazing removes air and contaminants from the process. This creates strong, reliable joints with minimal defects. The controlled environment ensures consistent results.

Can vacuum brazing join dissimilar metals?

Yes. Vacuum brazing can join metals like aluminum to copper or stainless steel. This flexibility supports complex assemblies in heat exchangers and electronic devices.

What maintenance does a vacuum brazing furnace require?

Operators must clean parts, check seals, and maintain vacuum pumps. Regular inspections and preventative maintenance keep the furnace running efficiently and extend its service life.

Is vacuum brazing environmentally friendly?

Vacuum brazing uses electricity and produces low emissions. The process avoids flux chemicals and reduces waste, supporting sustainable manufacturing practices.

How does automation impact vacuum brazing?

Automation controls temperature, pressure, and cycle timing. This reduces human error, increases production speed, and ensures consistent quality across batches.

What factors affect the cost of a vacuum brazing furnace?

Furnace size, customization, and advanced features influence cost. Facility requirements and ongoing maintenance also add to the total investment.

Does vacuum brazing require special operator skills?

Operators need training in vacuum technology, process control, and equipment maintenance. Skilled staff ensure high-quality results and safe operation.