Product Introduction

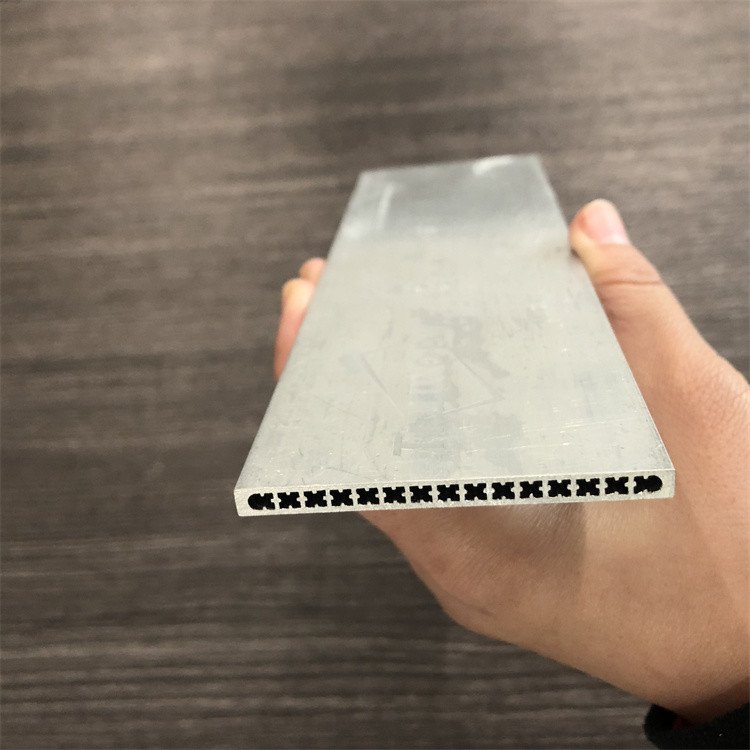

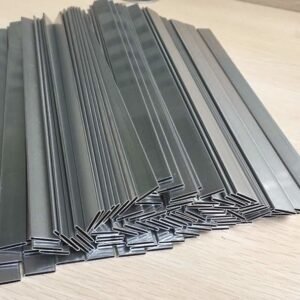

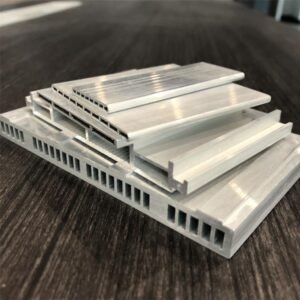

Seamless Multi-Port Aluminum Extruded Tubes for Heat Exchangers

Seamless micro-channel aluminum tubes are a critical component of automotive condensers and evaporators.

Optimized internal port geometry delivers turbulent, low-pressure-drop flow for maximum coolant contact and superior heat-transfer performance.

Extensive in-house die library covers all mainstream widths & port counts; custom profiles welcome.

Upload your drawing to our sales engineer—fast-tooling, tight-tolerance extrusion ready in 3–4 weeks.

• Type: Heat Exchanger Multiport Seamless Aluminium Extruded Tube

• Technical: Extruded

• Alloy: 1000series,3000series

• Temper: O, H14/H16

• Tube Size: Customized

• Wall Thickness: 0.25mm, 0.28mm or Customized

• Shape: Oval, Round

Multi-Port Seamless Aluminum Extruded Tubes

We start production from ingots and implement strict quality control; we have a large number of off-the-shelf molds and all parts are produced in-house, giving us a price advantage. – Sample orders accepted; small MOQ – Free samples are provided for you to check the quality; – Cost-effective and quick delivery; – Good communication skills, excellent service and detailed customized solutions

Product SKU: 99999

Product Brand: DAG

5