Product Introduction

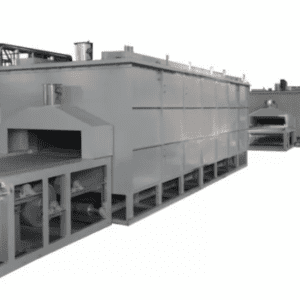

Round Fluxer Continuous Aluminum Brazing Furnace

| Machine Name: | Aluminum Radiator Brazing Furnace | Energy: | Electric |

| Muffle Length: | 4 Meter | Shape: | Round |

| Working Size: | 1200 * 250 Mm | Material: | 304 Stainless Steel |

| High Light: | continuous brazing furnace, furnace brazing equipment |

System composition

1. Rotary flux drum with integrated flux mixing & metering feed

2. Dry-off oven

3. Front curtain chamber

4. Pre-heat furnace

5. CAB brazing furnace

6. Air-cool chamber

7. Rear curtain chamber

8. Air-knock-off blower

9. Variable-speed drive train

10. Water/gas piping network

11. PLC + HMI electrical control package

Flux booth: fully 304 stainless, reinforced shell for 24/7 duty; cylindrical interior eliminates dead zones and flux pile-up, cutting flux consumption by ≈15 % and reducing overall aluminium radiator brazing line OPEX.

Technical Parameters

Round Fluxer Continuous Aluminum Brazing Furnace

Parameters of Aluminum Radiator Brazing Furnace

| Mesh belt operation surface height (to the ground) | 900mm |

| Mesh belt speed | 200~1000mm/min (inverter frequency conversion); |

| Effective working size | 1200mm (wide)×250mm(height above mesh belt) |

| Brazing oven effective working size | 7000mm (L)×1200mm (W)×250mm (H); |

| Preheating oven effective size | 4000mm (L)×1200mm(W)×250mm(H) |

| Brazing oven effective size | 6000mm(L)×1200mm(W)×250mm(H) |

| Total production line length | 36.7M |

| Total power | Electric power: 270KWFull power at a temperature rising, 60% at the brazing stage; ≤60% |

| Gas consumption | Max 66M3/H; about 52m3/h at operation; |

| 99.999% nitrogen supply | 200m3/h (actual consumption: 90-120m3/h) |

Technical Parameters of Round Fluxing Chamber

| Mesh belt operation height | 900mm |

| Effective working size | 1200mm (wide) ×250mm (straight height above mesh belt) |

| Conveyor chain | SUS304 (Horseshoe Chain) |

| Fluxing chamber | 400mm |

| Air blowing chamber | 600mm |

| Front entrance | 1500mm |

| Manual coating area | 1500mm |

| Total length | 4M |

Flux Spraying Device

| Taiwan diaphragm pump: 2 sets |

| Flux nozzle type and distance: double-row; front and rear nozzle overlapping spraying; right-left distance: 200mm |

| Flux nozzle quantity: 13 pieces |

Air blowing device

| High-pressure fan: model: 9-19; |

| Power: N = 7.5KW; |

| The height of the spray nozzle to the parts surface can be adjusted from 50 mm to 150 mm away from the workpiece surface. |

Flux tank

| Size: (304 stainless steel): Φ900mm *600mm (flux spray supply tank) |

| Mixer set: 1 set100 mesh filter net is installed to prevent impurities from entering the diaphragm pump |

Advantage

Round Fluxer Continuous Aluminum Brazing Furnace

1. All stainless steel 304 fluxing chambers and reinforced structures of the body can ensure long-term, trouble-free use of the spraying machine.

2. The fluxing can spray brazing flux to the core and the header. The easily dismantled nozzles can spray the workpiece accurately according to the requirements.

3. The aluminum radiator brazing furnace is designed with a manual coating area between the fluxing chamber and the drying oven.

4. The furnace’s fluxing chamber’s cylindrical design ensures that no flux accumulation occurs during the collection process. This reduces the aluminum radiator brazing furnace’s overall running cost.

5. The height of the air knife of the spray high-pressure fan can be adjusted to better remove the excess flux. The CAB aluminum radiator brazing furnace has a low running cost.

Continuous Aluminum CAB Brazing Furnace for Sale

A fully integrated Controlled-Atmosphere Brazing (CAB) line engineered for high-volume, low-cost production of aluminum radiators, condensers, evaporators and charge-air coolers. The circular-flux design guarantees uniform flux dosing, minimal waste and class-leading joint integrity. Designed & manufactured by DAG Shenzhen— full customizable, turnkey installation, worldwide commissioning, 24/7 technical support,affordable prices ,inquiries welcome.

Product SKU: 2

Product Brand: DAG

5

Reviews

There are no reviews yet.