Product Introduction

Aluminum Radiator Header Plate for Automotive Water Tanks

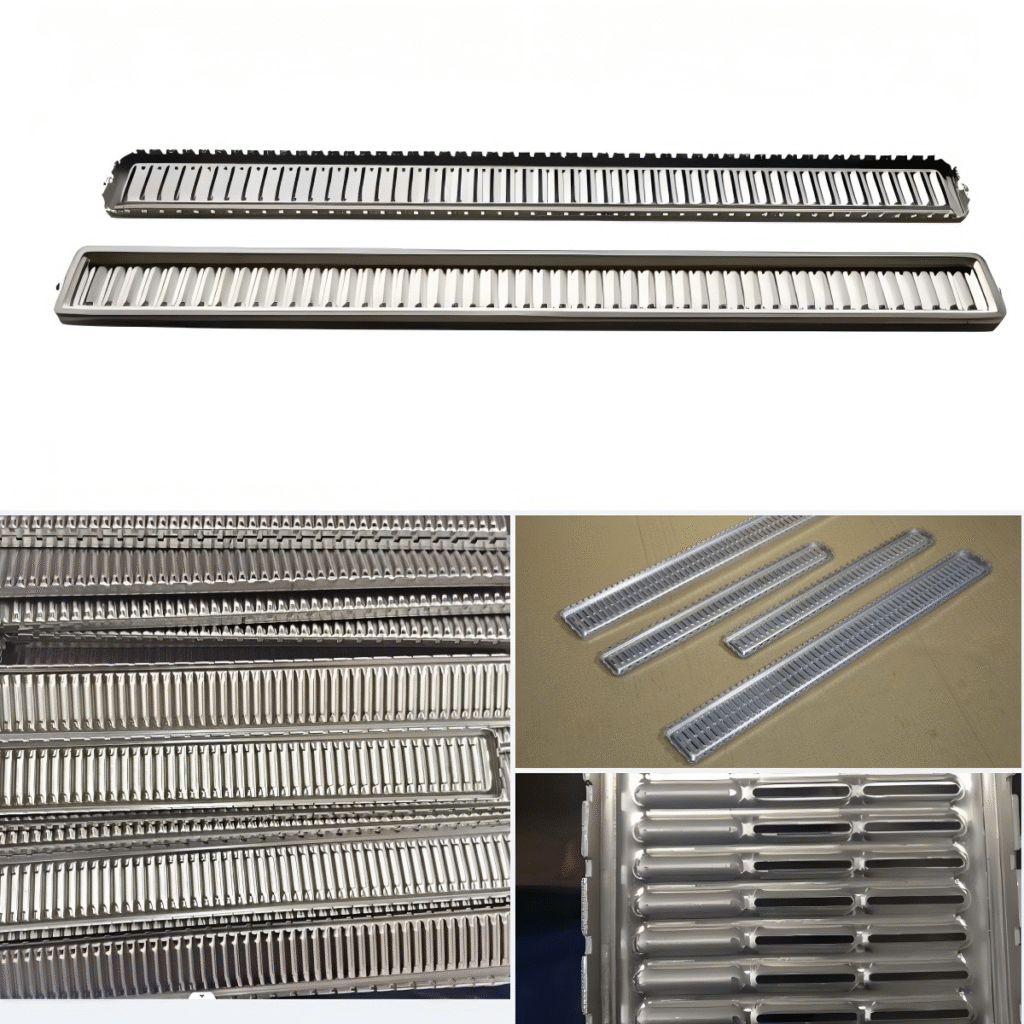

CNC-pierced and flux-coated, these AA3003+4343/4045 aluminum header plates form the precision interface between the radiator tank and the micro-channel core.

1. Thickness 1.5–3.0 mm, width up to 800 mm, length on request

2. Hole pattern ±0.05 mm true position, compatible with 6–90 port flat tubes and ISO/PAG brazing fixtures

3. Clad ratio 8–10 % each side, melts at 605 °C to create a self-healing fillet, eliminating post-braze leaks

4. Pre-temper H24, post-braze yield ≥95 MPa, salt-spray >1 000 h per ASTM B117

5. Laser-etched part number & 2-D code for 100 % traceability

Features

The gaps between the holes on the radiator header plate are the same. Burr-free and Smooth,High Strength, Heat Resistance, Corrosion Resistance

Applicable

Ready for CAB, NOCOLOK® or vacuum brazing lines—tight flatness (<0.1 mm/100 mm) guarantees uniform core-to-tank gap for robotic flame brazing.

Aluminum Automotive Radiator Header Plate

Free Samples, Customizable, Low MOQ, Factory-Direct Pricing, Affordable price, Worldwide Shipping—Request a Quote Today. • Rows: Customized • Processing method: Crimping • Width: Customized • Surface: Smoothness • Packaging: Carton Box • Application: Automotive Water Tanks

Product SKU: 99999

Product Brand: DAG

5