Product Details

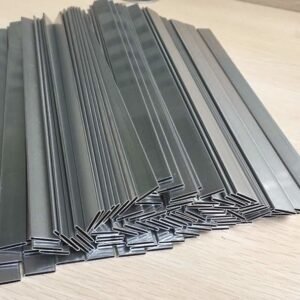

High Frequency Welded Aluminum Radiator Flat Pipe Tubes

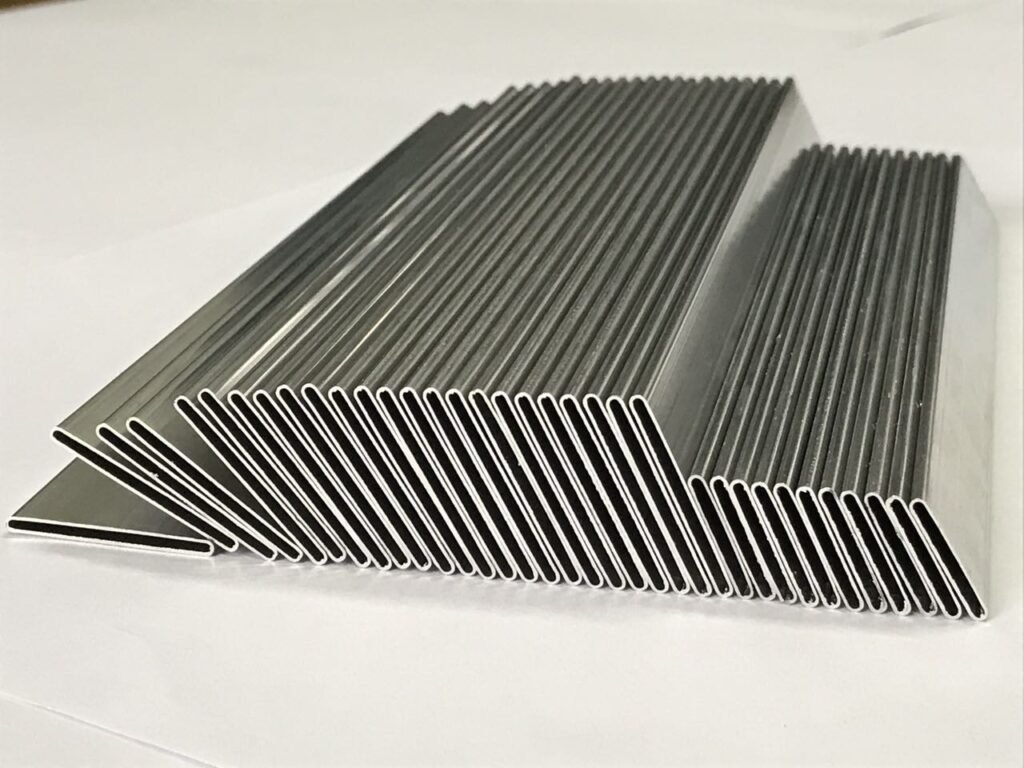

Compared to traditional porthole extrusion, the HF weld seam eliminates eccentricity and dead zones, boosting overall heat-transfer coefficient (HTC) by 35 % while cutting refrigerant charge by 40 %.

• Product Name: Aluminum Flat Tube

• Size: Customer Requirement

• Application: Heat Exchange Industry

• Material: Aluminum Alloy

• Color: Silver

• Surface: Polished

| specifications | thickness(mm) | width(mm) | weight(kg/m) |

| R16*1.4 | 0.3 | 34.1 | 0.0280302 |

| R16*1.5 | 0.26 | 34.1 | 0.02429284 |

| 0.28 | 34.1 | 0.02616152 | |

| 0.3 | 34.1 | 0.0280302 | |

| R16*1.7 | 0.28 | 34.4 | 0.02639168 |

| 0.3 | 34.4 | 0.0282768 | |

| R16*1.8 | 0.3 | 34.4 | 0.0282768 |

| R16*1.9 | 0.3 | 34.6 | 0.0284412 |

| R16*2.0 | 0.26 | 34.6 | 0.02464904 |

| R16*2.0 | 0.265 | 34.6 | 0.02512306 |

| 0.265 | 34.6 | 0.02512306 | |

| 0.28 | 34.6 | 0.02654512 | |

| 0.3 | 34.6 | 0.0284412 | |

| 0.32 | 34.6 | 0.03033728 | |

| 0.35 | 34.6 | 0.0331814 | |

| R18*1.5 | 0.3 | 38 | 0.031236 |

| R18*2.0 | 0.3 | 38.6 | 0.0317292 |

| R20*1.5 | 0.3 | 42 | 0.034524 |

| R20*2.0 | 0.3 | 42.6 | 0.0350172 |

| R22*1.5 | 0.3 | 46.1 | 0.0378942 |

| R22.5*1.5 | 0.3 | 46.4 | 0.0381408 |

| R22*2.0 | 0.26 | 46.6 | 0.03319784 |

| 0.28 | 46.6 | 0.03575152 | |

| 0.3 | 46.6 | 0.0383052 | |

| 0.32 | 46.6 | 0.04085888 | |

| R23.5*2.0 | 0.3 | 49.6 | 0.0407712 |

| 0.28 | 49.6 | 0.03805312 | |

| 0.3 | 49.6 | 0.0407712 | |

| R24*1.2 | 0.3 | 49.6 | 0.0407712 |

| R24*2.0 | 0.3 | 50.5 | 0.041511 |

| R26*1.2 | 0.265 | 53.7 | 0.03899157 |

| R26*1.4 | 0.28 | 54 | 0.0414288 |

| 0.3 | 53.8 | 0.0442236 | |

| R26*1.5 | 0.3 | 54 | 0.044388 |

| R26*1.75 | 0.3 | 0 | |

| 0.32 | 0 | ||

| R26*1.8 | 0.3 | 54.2 | 0.0445524 |

| R26*2.0 | 0.265 | 0 | |

| 0.28 | 0 | ||

| 0.3 | 54.4 | 0.0447168 | |

| 0.32 | 54.4 | 0.04769792 | |

| 0.35 | 54.4 | 0.0521696 | |

| 0.4 | 54.3 | 0.0595128 | |

| R27*1.2 | 0.265 | 55.7 | 0.04044377 |

| R27*2.0 | 0.3 | 56.4 | 0.0463608 |

| 29*2.88 | 0.3 | 61.5 | 0.050553 |

| R30*2.0 | 0.3 | 62.5 | 0.051375 |

| R32*1.5 | 0.3 | 66 | 0.054252 |

| R32*1.8 | 0.3 | 66.2 | 0.0544164 |

| R32*2.00 | 0.3 | 66.5 | 0.054663 |

| 0.32 | 66.5 | 0.0583072 | |

| 0.35 | 66.5 | 0.0637735 | |

| 0.4 | 66.4 | 0.0727744 | |

| R40*2.0 | 0.35 | 82.6 | 0.0792134 |

| R42*2.0 | 0.3 | 86.4 | 0.0710208 |

HF Welded Aluminum Radiator Flat Pipe Tubes-Affordable

High-precision machining center processing and precise transmission components ensure that the aluminum strip is precisely formed, and direct forming ensures that the surface of the pipe is not damaged, extending the service life. The precision high-frequency welding device ensures the precise welding of the precisely formed aluminum strip, and the welding pointer ensures the continuous and accurate positioning of the weld and keeps the welder’s energy focused on the weld, without leaking welds or weld deflection. Fully customizable, affordable price, global shipping.Welcome to Place Your Professional Order!

Product SKU: 99999

Product Brand: DAG

5