Products Summary

-

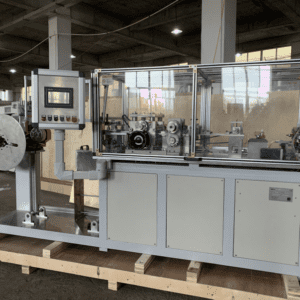

0.8Mpa Radiator Plastic Tank Crimping Machine

-

1.5mm Thickness Aluminum Header Plate for Car Radiator

-

16M Continuous Aluminum Brazing Furnace

-

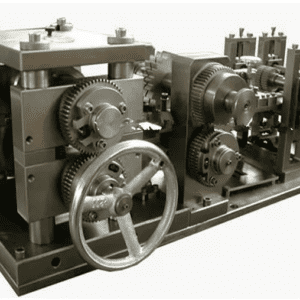

2 Row Radiator Core Builder Machine

-

280 M/Min High Speed Auto Radiator Fin Making Machine

-

3003 Aluminum Foil Radiator Fin Machine

-

4 Row Aluminum Automotive Radiator Core Builder Machine

-

5 Rows Automotive Radiator Core Builder Machine

-

500 Abarth L4 1.4L 2012-2015 RADIATOR PLASTIC TANK

-

ACCENT GL L4 1.6L 00-04 PLASTIC TANK

-

Affordable Aluminum Brazing Functional Additive

-

Affordable Car Aluminum Radiator Plastic Tank Crimping Machine

-

AFFORDABLE CITROEN NEMO 1.3 MT RADIATOR PLASTIC TANK FOR SALE

-

Affordable Extruded Aluminum Radiator Flat Oval Tubes

-

Affordable Harmonica Aluminum Extruded Micro Channel Flat Tube

radiator making machines

The machinery required for producing automotive radiators includes fin making machines, CNC punching machines, radiator core assembly/builder machines, nylon PA66-GF30 injection molding machines, radiator plastic tank crimping machines, leak detectors, laser marking machines, vacuum packaging machines, ultrasonic cleaning tanks, and brazing furnaces etc.

Complete Equipment List for Automotive Radiator Production

1. Aluminum Strip Preparation

– Precision slitting line (aluminum foil slitting line)

– High-speed fin press, 40-80 tons, servo feeding (fin press)

– High-frequency welding flat tube rolling mill, with online ECT (tube rolling mill)

2. Core Assembly

– Fully automatic core compactor and tube expander (core assembly machine)

– Servo tube expander (servo tube expander)

– CNC top plate forming center (top plate forming machine)

3. Controlled Atmosphere Brazing (CAB)

– Continuous nitrogen-protected CAB furnace, 600-650℃ (CAB furnace)

– Flux spraying and drying device (flux spraying and drying device)

– Visual inspection before and after brazing (brazing visual inspection station)

4. Plastic Water Tank Molding and Connection

– PA66-GF30 injection molding machine 850-1500 tons (Water Tank Injection Molding)

– Automatic Deburring Unit, Optional Low-Temperature Deburring (Deburring Unit)

– Servo Plastic Slot Riveting Machine, Long/Short Side (Servo Slot Riveting Machine)

5. Post-processing and Testing

– Helium Vacuum Chamber Leak Detector, 5 × 10⁻⁶ mbar·L/s (Helium Leak Detector)

– Dry Pressure and Flow Test Stand (Pressure and Flow Test Stand)

– VIN/QR Code Laser Marking Machine (Laser Marking Machine)

6. Packaging

– Robotic Palletizer (Robot Palletizer)

– Online Checkweighing and Labeling Machine (Checkweighing and Labeling Machine)

– Vacuum Packaging Machine

7. After-sales/Remanufacturing Equipment

– Manual Pneumatic Riveting Machine, Suitable for Small Batch Production (Pneumatic Riveting Machine)

– TIG Aluminum Repair Station with 4047 Welding Wire (Argon Arc Welding Station)

– Ultrasonic degreasing tank (ultrasonic degreaser) used for recycling weld cores.

10 Advantages of DaG Machines

1. High precision and accuracy: Our machines, with advanced technology and precise calibration, ensure that every product is manufactured with exceptional precision and accuracy, meeting the highest quality standards.

2. Minimal maintenance requirements: With robust construction and intelligent design, our machines have minimal maintenance requirements, reducing downtime and maintenance costs.

3. Customizable options to meet specific needs: We offer customizable options to tailor our machines to your needs, ensuring they fit perfectly into your production process.

4. Enhanced safety features: We prioritize safety in our machine design, incorporating enhanced safety features to protect operators and minimize the risk of accidents in the workplace.

5. Reduced waste and improved resource utilization: Our machines are engineered to minimize waste and optimize resource utilization, helping you achieve greater sustainability and cost savings.

6. User-friendly interface and intuitive controls: Our machines feature a user-friendly interface and intuitive controls, making it easy for operators to operate and monitor the machine with minimal training.

7. Integration with other production systems: Our machines are designed for seamless integration with different production systems, enabling you to optimize your entire production line and achieve greater efficiency.

8. Longevity and durability for extended machine lifespan: Our machines are built to last, with durable construction and high-quality components, ensuring a longer lifespan and reducing the need for frequent replacements.

9. Extensive support and training resources: We provide comprehensive support and training resources to ensure that you maximize the potential of our machines and achieve optimal results in your manufacturing operations.

10. Advanced technology and automation: Our machines incorporate advanced technology and automation, enhancing efficiency, accuracy, and productivity in your manufacturing operations.

Materials required for car radiators

Automotive Radiator Bill of Materials – Metal Core and Plastic Tank Module

1. Radiator Core (Main Heat Exchange Zone)

– Aluminum Brazing Rods/Fin Foil: 3003, 4343/3003/7072 multilayer composite aluminum, thickness 0.08–0.15 mm, double-sided 4–10% silicon pre-brazing layer

– High-Frequency Welded Flat Tubes: 6063 or modified 3003, width 16–26 mm, wall thickness ≥0.4 mm, with internal baffles or reinforcing ribs

– Manifold Plate: 3003+zinc composite aluminum, thickness 1.4–2.0 mm, CNC formed after stamping; 6061-T6 aluminum alloy optional, suitable for higher burst pressure

– Side Plates/Reinforcing Ribs: 3003-H24, thickness 0.8–1.2 mm, used as mounting brackets and thermal expansion buffer layers

2. Plastic Tank (Top and Bottom)

– Glass fiber reinforced nylon PA66-GF25/30: Resistant to ethylene glycol-water, hydrolysis, continuous operating temperature range -40℃ to 135℃; injection molded, tolerance ±0.1 mm

– Static seal: Peroxide-cured EPDM or AEM, Shore A hardness 70±5, compression set ≤20% (125℃ × 70 hours)

3. Connections and auxiliary consumables

– Brazing filler: Coated 4343/4045, melting point range 577–605℃; NOCOLOK® potassium fluoroaluminate flux, particle size 2–20 µm

– Desiccant pack (for maintainable tanks): 3 g silica gel or molecular sieve to prevent condensation during transport

– Mounting hardware: AISI 304 stainless steel or aluminum rivets, resistant to electrochemical corrosion

4. Aftermarket/remanufactured add-ons

– Aluminum brazing wire: 4047 or 4043, 1.2–2.0 mm in diameter, for repairing cracks in flat tubes

– Two-component aluminum epoxy resin: curing temperature up to 120 °C, for sealing non-pressure pinholes

– Copper storage tanks (traditional and high-density applications): Cu-DHP phosphated deoxidized copper, wall thickness 0.5–0.8 mm, solder or silver solder

This bill of materials covers OEM mass production, service replacement, and short-lead-time remanufacturing—can be used directly for inquiries or uploaded to ERP systems.

Automobile radiator plastic tank production process

People Also Ask

Q: What products can your radiator core builder machine produce?

A: Our assembly machine can produce radiators, condensers, and intercoolers. We can customize the machine according to your needs.

Q: What is the maximum size of the radiator produced by your assembly machine?

A: Our maximum assembly size is L1800 * W1200 * T56mm. However, we can customize the machine according to your size.

Q:Can fins of different heights be assembled on the same radiator core builder machine?

A: The core machine can only assemble cores with a single fin height. We must customize fins of different heights if you need to assemble them.

Q: Is it possible to assemble fins of the same height in the radiator core and condenser core on the same radiator core builder machine?

A: No, because the radiator and condenser pipes are very different and cannot be mixed.

Q: Can the same radiator fin-forming machine produce different fin models?

A: The fin-forming roller is changeable, and different fin models can be produced on the same machine.

Q: What is the size of the fins produced by the radiator fin-forming machine?

A: Fin thickness: 0.07-0.08mm; fin width: 8-200mm; we can customize the machine according to size.

Q: What metal materials can the heat sink forming machine process?

A: Aluminum foil material: 3003-H16, Copper material: H62.

Q: How many types of radiator plastic tank crimping machines are there?

A:Our company supplies manual plastic tank crimping machines, semi-automatic pneumatic and servo-type plastic tank clinching machines, hydraulic and pneumatic-type plastic tank crimping machines, and fully automatic plastic tank clinching machines. We can customize the machines according to your needs.

Q: Which one is better, an automatic crimping machine or a semi-automatic crimping machine?

A: An automatic crimping machine is suitable for a single model order of 300 sets or more at a time. It is ideal for this production plan, as it has more models but less quantity.

Q: How many model types can an automatic radiator plastic tank crimping machine system store?

A: Because it is a PLC interface setting, it can store about 200 different tank models and positions and covers most car models.

Q: What is the maximum size of the radiator produced by your plastic tank crimping machine?

A: The maximum workpiece size we produce is L1000*W900mm, and we can customize the machine according to your size.