What Makes an Aluminum Brazing Furnace Truly Energy Efficient

An energy-efficient aluminum brazing furnace has special insulation. It uses exact temperature control and smart air management. Automation and regular care help it work better. DAG makes its furnaces to use less energy and save money. The furnaces also make high-quality parts. These things make the brazing process steady and efficient.

Why Leading Manufacturers Prefer Aluminum Brazing to Welding

Leading manufacturers pick aluminum brazing as the best way to join metal without welding. It is chosen for being fast, saving money, and making strong joints. They use the aluminum brazing furnace from DAG to help with making aluminum radiators, heat exchangers, and cars. In many cases, aluminum brazing has clear benefits: These good points […]

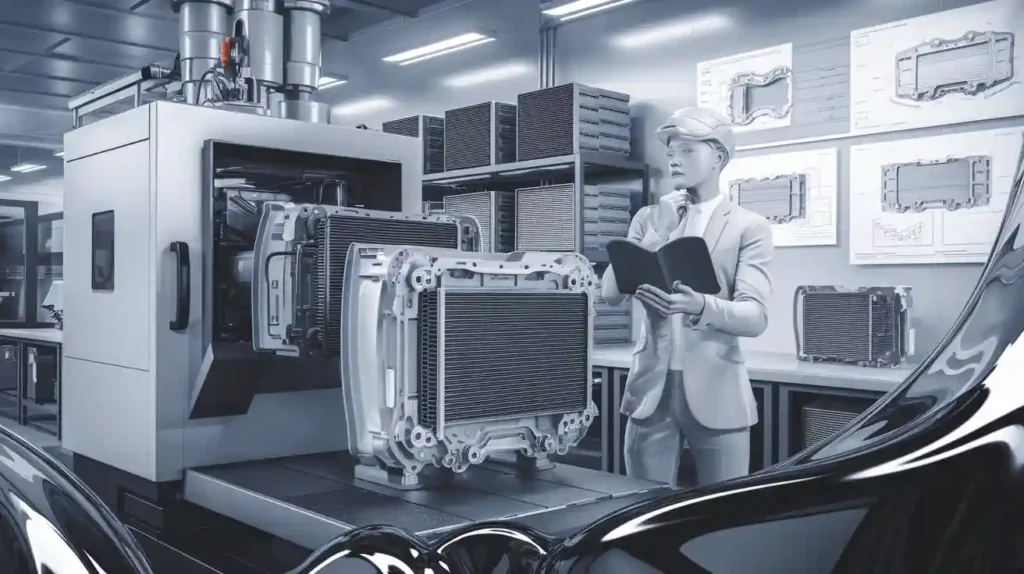

Applications of Aluminum Brazing Furnaces in the Automotive Industry

Aluminum brazing furnaces are important in making cars. They help join parts like heat exchangers, radiators, and condensers. The connections are strong and exact. Many car makers use new furnace designs. These designs give better control and make the process repeat the same way. DAG gives aluminum brazing furnace solutions for cars. These solutions use real-time temperature control and atmosphere management. These features help lower mistakes and make more parts faster. They also help meet the need for light and tough parts by brazing automotive heat exchangers.

A Complete Guide to Buying an Automobile Radiator Making Machine

DAG gives Radiator Making Machine solutions with good quality, custom choices, and help when needed. Buying a machine that fits your radiator line gives you value for a long time, steady quality, and dependable work.

Vacuum Aluminum Brazing Furnace vs Vacuum Heat Treat Kiln How to Decide for Your Production Needs

The vacuum aluminum brazing furnace is best for making many aluminum heat exchangers. It gives clean and strong brazed joints. If you need to work with different metals, a vacuum heat treat kiln is better. It also helps if you need many heat treatment steps. You get more process choices with a vacuum heat treat kiln. You should think about what materials you use. You should also think about the brazing method and process type. Vacuum control, how much you need to make, and the quality you want are important too. Each vacuum brazing furnace and aluminum brazing furnace works in its own way. The best choice is the one that fits your brazing and production needs.

Aluminum brazing furnace vs crucible for aluminum melting

Explore key differences between aluminum brazing furnaces and crucibles for melting aluminum.

For aluminum melting, many people think the aluminum brazing furnace works better. It gives more control over heat and keeps the quality steady. This way is good for people who want the same results every time and need to melt a lot of aluminum. Some people pick a crucible because it is cheaper and simpler to use. It is best for small jobs. Using an aluminum brazing furnace can make things safer and the quality better. A crucible is better for fast and easy melting jobs.

Which Radiator Header Plate Stands Out in 2025

DAG Radiator Header Plate stands out in 2025 by using advanced aluminum alloys that provide excellent cooling performance and can be customized to fit various needs. Choosing the right radiator header plate is essential for vehicles handling heat and heavy-duty work. Studies show that quality radiator header plates protect engines and improve their efficiency. Tests confirm that the radiator header plate prevents breaks at tube joints, helping engines avoid overheating. As a trusted radiator header plate supplier, DAG ensures vehicles stay safe and perform reliably today.

Understanding Vacuum Heat Treatment Furnaces in 2025

A vacuum heat treatment furnace works with metals in a vacuum. This helps make the metal better. The furnace takes away oxygen. This stops oxidation and keeps the metal clean during heat treatment. The vacuum gives even heating and cooling. This makes the surfaces cleaner and the parts stronger. The process helps make good products for cars and electronics. The world market for vacuum heat treatment furnaces may reach about USD 1.1 billion in 2025. This shows the market is growing.

What to Look for in an Aluminum Brazing Furnace

Selecting the right aluminum brazing furnace requires understanding your specific production needs and quality standards. You need to consider your desired output and the level of quality you expect. Manufacturers look for a brazing furnace that prevents issues such as pinholes and warping, while also ensuring strong, durable joints. Achieving this relies on precise control of both atmosphere and temperature. Many industries require an aluminum brazing furnace that can handle a variety of product shapes and sizes, as well as rapid heating capabilities. It’s also important that the brazing furnace integrates seamlessly with other equipment, such as degreasers or fluxers. Consistent heat distribution and stable control are essential for optimal brazing results. Companies rely on a brazing furnace that delivers all these features to produce high-quality aluminum components.

Pros and Cons of Vacuum Brazing Furnaces for Metal Joining in 2025

Vacuum brazing furnaces deliver high-quality, oxide-free joints essential for industries such as automotive and aerospace. Manufacturers value the vacuum brazing furnace for its clean process, uniform temperature control, and ability to join dissimilar metals. However, a brazing furnace demands significant investment and technical expertise. In 2025, the global vacuum brazing furnace market continues to grow, driven by automation and increased demand in sectors like electric vehicles. Solutions such as DAG’s Giant Vacuum Aluminum Brazing Furnace set new standards for precision and efficiency.