What Sets Radiator Fin Machines Apart in Industrial Production

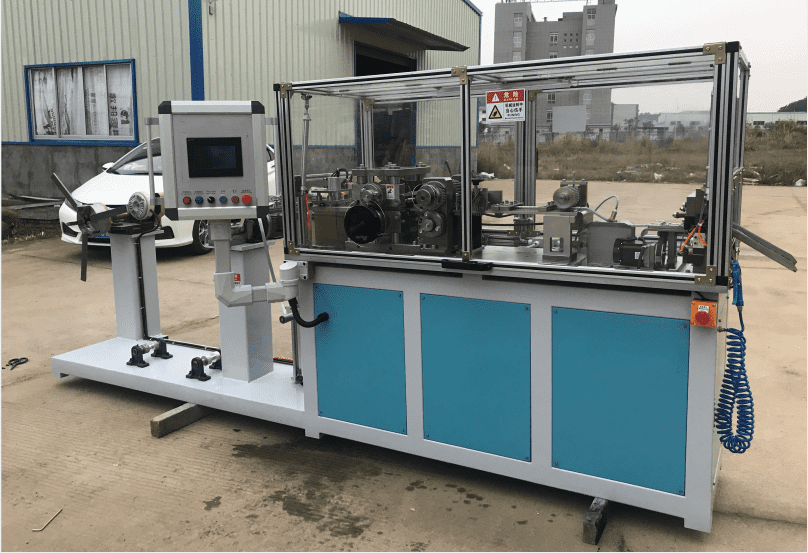

Radiator fin machines are important in today’s factories. These machines make metal fins for radiator systems fast and well. Companies want things like PLC controls and servo motors. These help make every fin the same size each time. DAG is known around the world for its special machines. Their machines use touch screens and smart […]

How to Choose the Right Radiator Fin Forming Machine

Choosing the right radiator fin forming machine starts with knowing what you need. A business must make sure the machine’s output and features fit its radiator line. Each machine must work with the needed radiator fin types and materials. DAG gives advanced technology for many radiator uses. A good machine will make radiator quality better […]

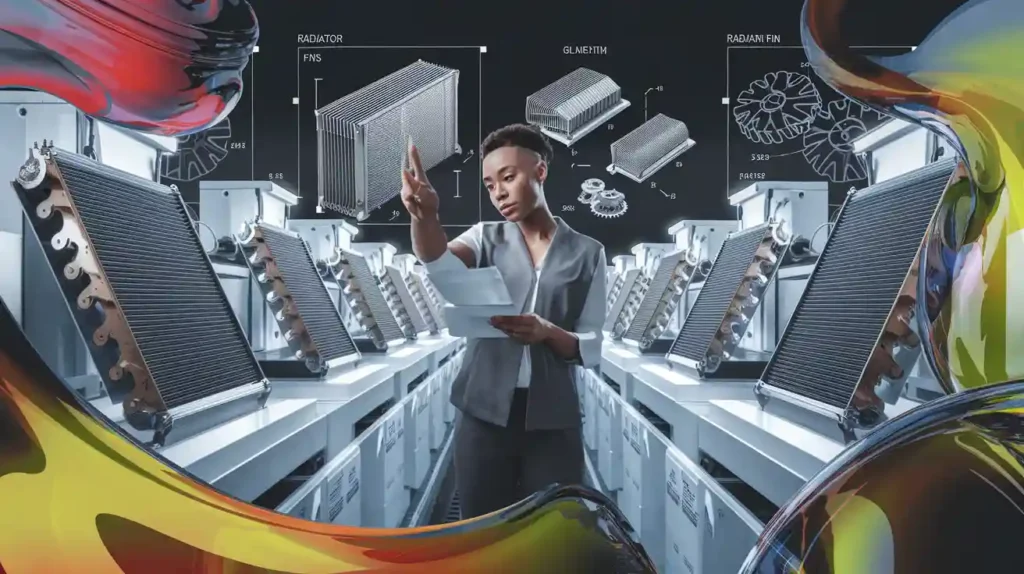

How to Choose the Right Radiator Fin Machine for Your Business

Choosing the right radiator fin machine can change how well your factory works and how good your products are. Factories need these machines to make radiator fins for cars, air conditioners, and other machines. New radiator fin forming machine models have smart controls and use automation. This helps factories make fins that are the right size and always good quality. DAG has machines that work with aluminum and copper. They can make fins fast and can handle many types of fins. Companies should think about how much they need to make, what kinds of fins they need, what materials they use, and if the supplier is trusted before picking a machine.

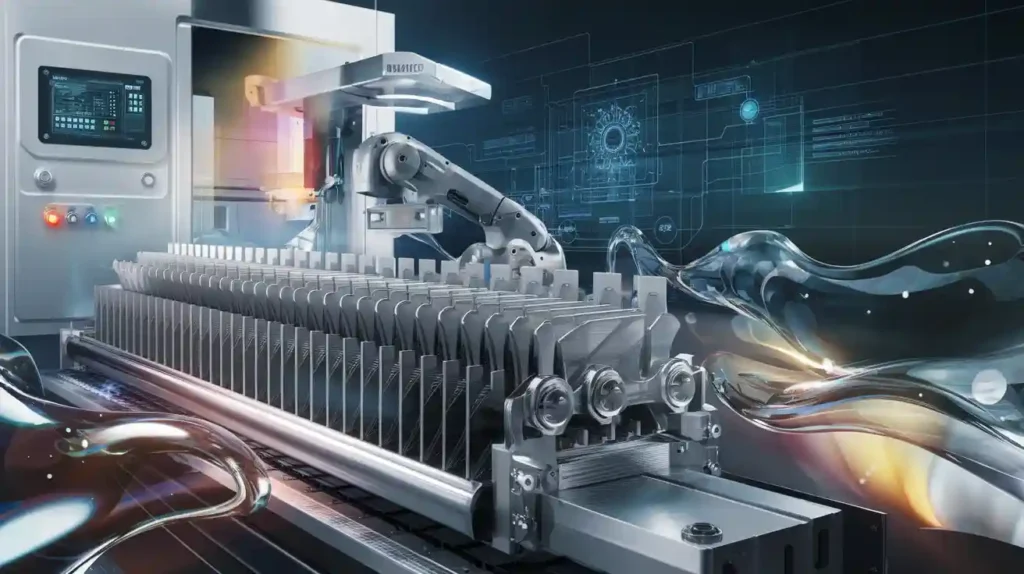

Radiator Fin Forming Machine Innovations Shaping 2025

Radiator fin forming machine technology in 2025 changes how car radiators are made. Automation, AI, and IoT help at every step. DAG is a leader with new radiator ideas that make things faster and better. Smart sensors and CAD tools help the radiator machine make good fins for car radiator systems and HVAC. Real-time data helps machines work better and last longer. New aluminum alloys and coatings help the planet. The Plate Fin Radiator Market will grow a lot because more people want car radiators and smart radiator ideas. These changes show how technology and quality will shape radiator machines and car radiator products in the future.

Radiator Fin Machine Breakthroughs Transforming Manufacturing in 2025

Radiator fin machine technology in 2025 brings better speed and quality to factories. AI, IoT-enabled sensors, and new materials help radiator machine workers make products faster with less waste.

Top 3 Condenser Machine Picks for Industrial Use

Air-cooled, water-cooled, and evaporative condenser machine types help factories work better today. Picking the right condenser machine affects how well things run, how often they break, and how much they cost. Lately, more people choose air-cooled models because water is hard to find and they are easier to take care of. But water-cooled and evaporative types are still needed for big jobs with lots of heat. Companies now use advanced radiator making machine solutions like the Radiator Fin Forming Machine to make sure their work is exact and can change for tough jobs.

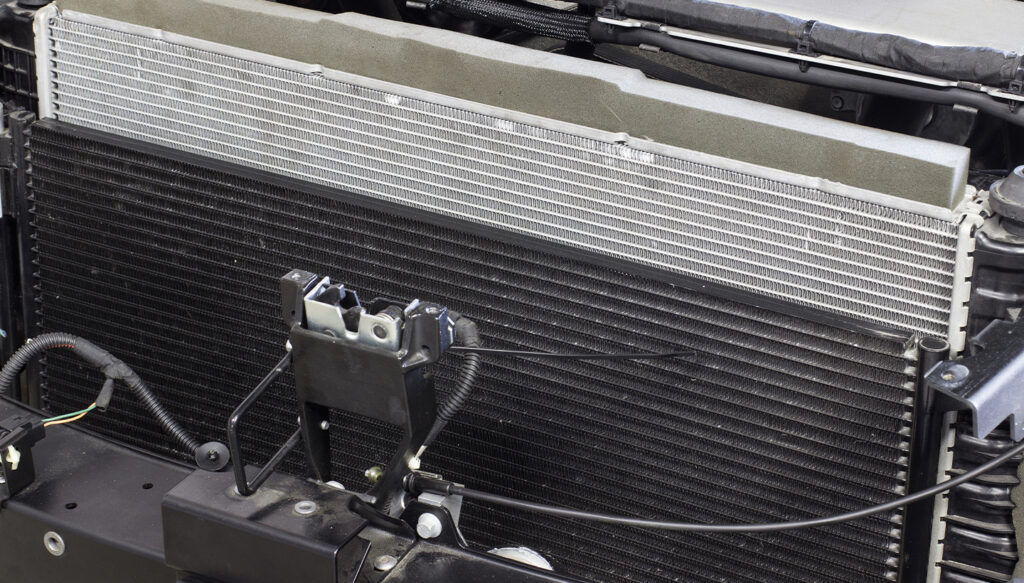

An In-depth Look at Car Radiator Fin Forming Machines

The Car Radiator Fin Forming Machine creates the delicate and intricate fin patterns seen on radiator cores. These fins are crucial for the radiator’s function, as they enhance the surface area for heat to dissipate, thus maintaining the engine’s temperature.