Understanding Vacuum Heat Treatment Furnaces in 2025

A vacuum heat treatment furnace works with metals in a vacuum. This helps make the metal better. The furnace takes away oxygen. This stops oxidation and keeps the metal clean during heat treatment. The vacuum gives even heating and cooling. This makes the surfaces cleaner and the parts stronger. The process helps make good products for cars and electronics. The world market for vacuum heat treatment furnaces may reach about USD 1.1 billion in 2025. This shows the market is growing.

What to Look for in an Aluminum Brazing Furnace

Selecting the right aluminum brazing furnace requires understanding your specific production needs and quality standards. You need to consider your desired output and the level of quality you expect. Manufacturers look for a brazing furnace that prevents issues such as pinholes and warping, while also ensuring strong, durable joints. Achieving this relies on precise control of both atmosphere and temperature. Many industries require an aluminum brazing furnace that can handle a variety of product shapes and sizes, as well as rapid heating capabilities. It’s also important that the brazing furnace integrates seamlessly with other equipment, such as degreasers or fluxers. Consistent heat distribution and stable control are essential for optimal brazing results. Companies rely on a brazing furnace that delivers all these features to produce high-quality aluminum components.

Pros and Cons of Vacuum Brazing Furnaces for Metal Joining in 2025

Vacuum brazing furnaces deliver high-quality, oxide-free joints essential for industries such as automotive and aerospace. Manufacturers value the vacuum brazing furnace for its clean process, uniform temperature control, and ability to join dissimilar metals. However, a brazing furnace demands significant investment and technical expertise. In 2025, the global vacuum brazing furnace market continues to grow, driven by automation and increased demand in sectors like electric vehicles. Solutions such as DAG’s Giant Vacuum Aluminum Brazing Furnace set new standards for precision and efficiency.

Comparing Continuous Brazing Furnaces with Batch and Vacuum Types for Modern Manufacturing

Manufacturers pick the right brazing furnace by looking at their production quantity needs, what materials they use, and what the process requires. A continuous brazing furnace works well for making lots of parts fast. It is good for places like car radiator factories. These places need things done quickly and the same way every time. Batch furnaces are better if you make smaller amounts or change products often. Vacuum furnaces are used when you need very clean air and high quality. They are important for things like airplane and medical parts.

Brazed Aluminum Radiators: Benefits and Drawbacks Uncovered

Brazed aluminum radiators are popular because they are light. They cool engines well and do not rust easily. Many car experts pick a braze aluminum radiator for new cars.

Top Trends Shaping Aluminum Brazing Ovens in 2025

Aluminum brazing oven trends in 2025 bring big changes worldwide. Manufacturers and engineers notice how new technology in Aluminum Brazing Furnace can change furnace brazing services. These trends change how efficient, high-quality, and eco-friendly every market sector is.

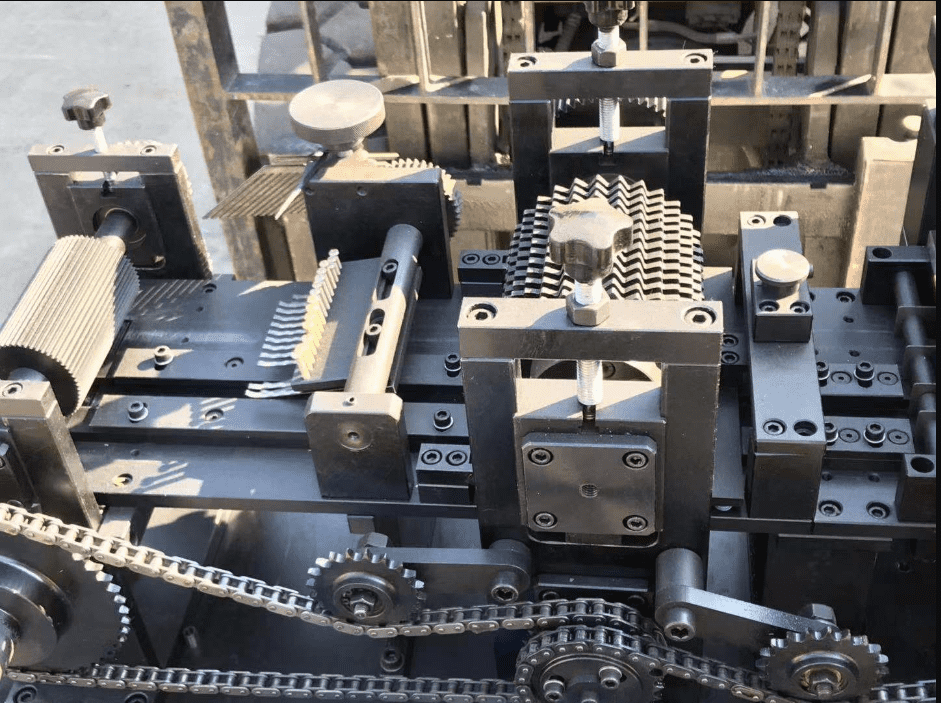

A Complete Guide to Choosing the Right Radiator Fin Forming Machine Manufacturer

Many businesses want to find the best radiator fin forming machine manufacturer. Companies understand that picking the right partner affects how well thermal management works. Choosing a radiator fin forming machine manufacturer needs careful thinking about machine quality and business goals. Good thermal management needs equipment that works well and helpful support. Each Fin Forming Machine should handle the needs of modern thermal management. Careful planning helps bring success and lasting value.

Automotive Radiator Core Making Machines That Stand Out in 2025

Manufacturers looking for the best automotive radiator core making machine in 2025 will see top choices like DAG and the ZPX-280 model. These machines work well because they use a lot of automation. They make products quickly and can be changed for special needs. They can handle many core sizes and fin types. This helps them fit new car needs. The industry is moving toward electric and hybrid vehicles. This change means there is more need for real-time thermal management. There is also more use of materials like aluminum that are better for the environment.

The Comprehensive Guide to Radiator Fin Forming Machines

Are you looking for radiator fin forming machines for the production of automotive radiators, air conditioners, and refrigeration units? This comprehensive guide will help you choose the right machine.

Fully Automatic Aluminum Automotive Plastic Water Tank Crimping Machines

Need a plastic water tank crimping machine for car radiator manufacturing? Check out the best fully automatic aluminium automotive plastic water tank crimping machine to upgrade your business.