Product Introduction

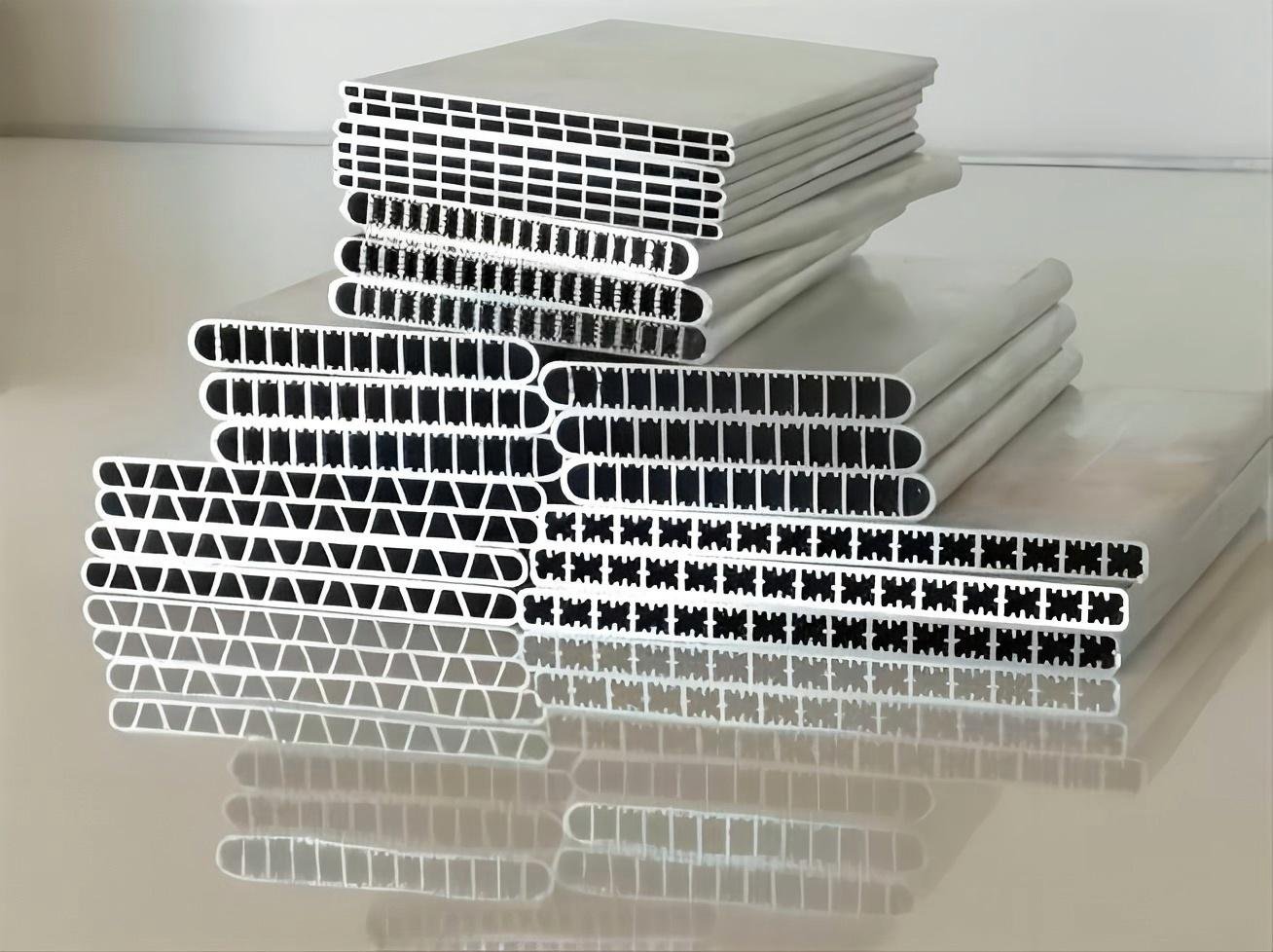

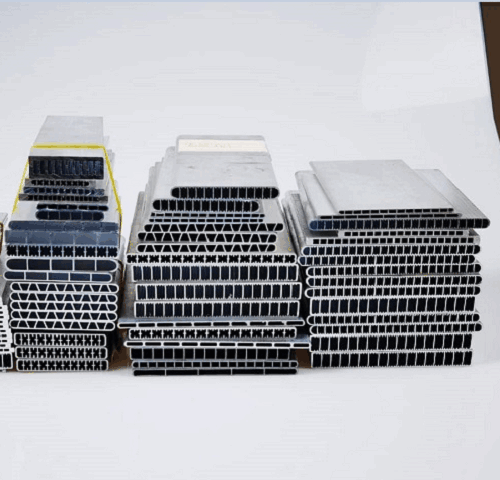

Aluminum Microchannel Oil Cooler Tube

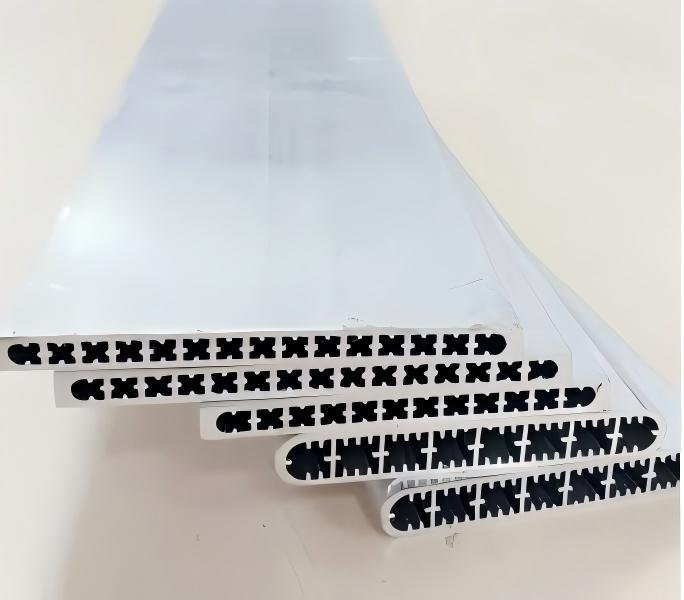

Aluminum microchannel oil cooling tube is a thin-walled porous flat tube material, which is formed by hot extrusion of refined aluminum rods and treated with zinc spraying on the surface. It improves heat transfer efficiency through a higher surface area/volume ratio, has the advantages of light weight and corrosion resistance, and is a key material for the new generation of parallel flow microchannel air conditioning heat exchangers.

| Item | Range |

| Fixed length | 200mm-4000mm |

| Width (micro-channel tubes) | 8mm-60mm |

| Width (large multi-channel) | 60-200mm |

| Thickness | 1mm-5mm |

| Wall thickness | 0.15mm-0.6mm |

| Thickness of zinc spraying | 5g/㎡-15g/㎡ |

| Thickness of flux coating | 8g/㎡-25g/㎡ |

Product Feature

The aluminum microchannel oil cooler tube, with its porous extrusion molding and enlarged internal fins and channel contact surface, increases the overall heat transfer coefficient (HTC) by ≥30% compared to traditional circular tubes, while reducing energy consumption by 15%.

1. Lightweight

2. Corrosion resistance

3. Excellent heat transfer performance

4. Tighter tolerances

5 . Reduce assembly time

6 .High level of surface quality

Application

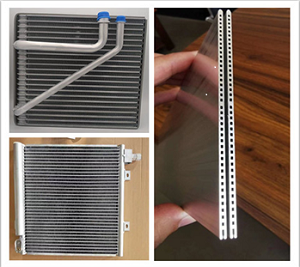

1. Car air conditioner

2 . Condenser

3 . Evaporator

4. Household air conditioner

5 . Oil cooler

6. Intercooler

7. EV Battery cooling

8 .ESS battery module cooling

FAQ

Q: What is your minimum order quantity?

A: The minimum order quantity depends on the design and requirements you want.

Q: Can you provide samples?

A: Yes, we will provide samples for you to check the quality, you only need to pay the shipping cost.

Q: How many types of product specifications and sizes are there?

A: It can be customized according to your requirements.

Affordable Aluminum Microchannel Oil Cooler Tube

luminum microchannel oil cooling tube is the core material of the new generation of condensers. Microchannel condensing tubes have outstanding performance in environmental protection, high efficiency, energy saving, and cost reduction, and have been widely recognised in automotive air-conditioning systems. We have good cooperation experience with big customers all over the world; Fast delivery time; Acceptable sample order; High cost performance; Good communication skills, good service and understanding of customers. Fully customizable, affordable price, global shipping.Welcome to Place Your Professional Order!

Product SKU: 99999

Product Brand: DAG

5