DAG, Atlas Radiator Inc, Guangdong Faret Auto Radiator, Radiator Supply House, and American Radiator are trusted suppliers in the car industry. These companies help radiator makers who want machines that work well and give the same good results every time. Many buyers from Egypt, Iran, and Europe pick their radiator making machine for cars and trucks, which shows people around the world trust them. DAG’s radiator making machine and tank radiator making machines help make radiators for both cars and trucks, so car makers can give strong and safe radiators. High customer happiness, good technical help, and OEM services make these suppliers a top pick for the car industry.

Key Takeaways

- Top radiator machine suppliers like DAG and Atlas Radiator Inc give strong, good machines for cars and trucks. Good product quality comes from tough materials, smart controls, and strict rules like ISO 9001 and ASTM D3306. Certifications like ISO 9001 and IATF 16949 show suppliers follow world rules for safety and quality. Good after-sales support means help with setup, fixing, training, and fast technical help. Suppliers who work worldwide can send machines faster and give better local help. Customer reputation is important; buyers trust suppliers with fair prices, easy-to-find parts, and friendly service. Picking the right supplier means matching what they do best to your factory’s size, needs, and plans to grow. Going to supplier sites and watching demos helps make sure machines fit your quality and custom needs.

Trust Factors for Radiator Machine Suppliers

Product Quality

Radiator makers need good product quality for their cooling systems to work well. Good products start with strong materials like aluminum and copper. These materials help move heat away and stop rust, which is important for cars. Makers use careful steps when making tubes, fins, and putting parts together. They also use special rules like ISO 9001 and ASTM D3306 to make sure each radiator is safe and good for the environment.

Key quality rules for radiator machines are:

- Must follow ISO 9001 for quality and ASTM D3306 for coolant.

- Use strong materials, mostly aluminum, for long life and good heat flow.

- Use smart controls and check often, like X-ray and pressure tests, to make sure welds and seals are good.

- Keep good records so they can track parts and help after sales.

- Always try to get better by listening to customers and checking quality.

New radiator machines use things like no-flux brazing and laser welding. These ways make radiators stronger and leave less bad stuff behind. Electrophoretic coating helps stop rust, so radiators last longer. Aluminum radiators cool fast and are light, which helps cars work better and makes radiators last longer. Strong machines and robots help make radiators that are always good and work well.

Certifications

Certifications help people trust radiator makers and suppliers. Top suppliers have big certifications that show they care about quality and safety. These papers prove a supplier uses good rules when making and running their business.

| Certification Standard | Notes |

|---|---|

| IATF 16949 | Automotive quality management standard |

| ISO/TS 16949 | Automotive quality management standard |

| ISO 9001 | Quality management, including ISO 9001:2015 |

| ISO 14000 | Environmental management standards |

| ISO 14001:2015 | Specific version of ISO 14000 series |

| NBBI | Boiler & Pressure Vessel certification |

Suppliers with ISO 9001 or CE show they follow world rules and care about safety. They check quality in many steps and give full reports. These certifications tell radiator makers that the supplier gives good products and uses the best ways to make cooling systems.

After-Sales Support

After-sales support helps radiator makers keep their machines working well and build trust with suppliers. Top suppliers give many services to keep radiator machines running right. These services are setup, regular checks, fixing, spare parts, teaching, and tech help.

| After-Sales Support Type | Description |

|---|---|

| Installation / Commissioning | Makes sure machines are set up and work right. |

| Maintenance / Inspection | Regular checks to stop problems and find them early. |

| Repair Services | Skilled workers fix machines fast. |

| Spare Parts Management | Easy and quick way to get real or good spare parts. |

| Training | Teaches workers how to use machines and learn new things. |

| Technical Support / Customer Service | Many ways to get help with questions and problems. |

| Upgrades / Retrofits | Adds new tech or features to old machines. |

| Customer Satisfaction Analysis | Gets feedback to make service and products better. |

Makers like fast answers and quick fixes. Good engineers and helpful teams solve problems and stop long waits. Many customers say suppliers are professional, quick, and always ready to help. These services make people trust the supplier and want to buy again. Strong after-sales support helps radiator makers give good cooling for cars and trucks.

Global Reach

Radiator machine suppliers with a big global reach help many countries. They send machines for automotive cooling systems all over the world. A large export network lets buyers get machines fast and with less worry. China, the United States, and Sri Lanka are top countries for shipping. The table below shows how many machines they send:

| Country | Number of Shipments | Number of Export Destinations | Key Export Markets |

|---|---|---|---|

| China | 336 | Not explicitly stated | Largest exporter overall |

| United States | 86 | 19 | Peru, Colombia, Mexico |

| Sri Lanka | 77 | Not explicitly stated | N/A |

China sends the most radiator machines for automotive cooling systems. The United States ships to 19 countries, mostly in the Americas. A supplier with a global network can send machines to many places. This helps radiator makers keep their factories working.

Websites like Global Trade Plaza and Volza connect suppliers and buyers from over 35 countries. These sites use safe payment methods and work with shipping companies. They make it simple for buyers to get radiator machines for automotive cooling systems. Big data checks lots of shipments and matches buyers with good suppliers. This helps buyers trust the process and find the right machines for their needs.

A global reach also means better help after buying. Suppliers with offices or partners in other countries can send parts and workers faster. This means less waiting for radiator makers. It also helps car companies keep their cooling systems working well.

Tip: Pick a radiator machine supplier with a good export record and strong shipping support. This helps you get fast delivery and good service for your cooling systems.

Customer Reputation

Customer reputation shows if a radiator machine supplier meets what car makers need. Buyers talk about their experiences with radiator machines for automotive cooling systems. Good reviews mention fair prices, parts in stock, and helpful workers. Many people like that suppliers honor warranties and offer many products for automotive cooling.

- Customers like:

- Good prices on radiator machines

- Parts ready for quick fixes

- Lifetime warranties that suppliers keep

- Friendly and smart workers

- Fast and personal help

- Extra products for cooling systems

Some customers have problems with repairs or warranty help. They talk about price jumps or broken radiators. These reviews help new buyers pick the best supplier for automotive cooling systems.

A supplier’s reputation depends on trust, help, and product quality. The table below shows how top radiator machine suppliers compare:

| Supplier | Customer Trust Factors | Support & Service Highlights | Reputation Summary |

|---|---|---|---|

| Majestic Company | Trusted for quality and innovation | Focus on customer happiness | Leader due to quality and customer focus |

| FTH Industries | Fast responses, good after-sales help | Manuals, videos, replies within one business day | Trusted for quick answers and training |

| Atlas Radiator Inc | Reliable machines, good post-sale help | Training for workers, spare parts support | Chosen for effective after-sales service |

| Talan Industries | Machines for large jobs, flexible designs | Fast technical support, setup and training | Helps customers improve production efficiency |

| Dezhou Chuangtao | Strong quality control, ISO 9001 and CE certified | Skilled support team, custom machines | Trusted for machine reliability and support |

| DAG | Full automation, 24/7 support, easy to use | Training, brand customization | High repeat customer rate due to trust |

| IEA, LLC | Durable machines, fast delivery | Good technical support, flexible designs | Supports new companies quickly |

Suppliers like DAG and Atlas Radiator Inc get high marks for trust and help. Many customers come back to buy more radiator machines and parts. A good reputation makes buyers feel sure when picking a supplier for automotive cooling systems.

Radiator Making Machine for Cars and Trucks: Top Suppliers

DAG

Company Overview

DAG is a top supplier in the radiator making machine business. The company makes machines for both cars and trucks. DAG is known for good products and machines that work well. Their factory is in China. They sell to radiator factories in many places around the world.

Product Features

DAG’s 1.5 KW Aluminum Car Radiator Plastic Tank Crimping Machine is important in making radiators. This machine puts the plastic tank on the radiator core. It makes sure the seal is tight so cooling works well. The machine uses servo and pneumatic systems for exact crimping. It can work with header-to-header distances from 350 to 950 mm. It also fits header plate lengths from 100 to 800 mm. You can change the clinching speed and teeth pitch. This helps make different radiator sizes. The machine can make about 25 cores every hour. It is good for medium-sized factories. The strong build and energy-saving design help it work well in tough places.

Strengths

DAG’s radiator making machine for cars and trucks has many good points:

- High automation means fewer mistakes by people.

- The design lets you make many radiator types and sizes.

- Fast speed helps make more radiators.

- The machine uses strong materials so it lasts long.

- 24/7 technical support and training help keep work going.

- The company gives a one-year warranty and safe packaging for shipping.

Customer Insights

Customers are very happy with DAG’s radiator making machine for cars and trucks. Many say the machine is easy to use and does not break often. The brand has a 95% repurchase rate, which shows people trust it. Users like the technical support and training they get. They also like that the machine is reliable, flexible, and fast. Automation and accuracy help stop mistakes and save time. This makes DAG a top pick for radiator makers.

Atlas Radiator Inc

Company Overview

Atlas Radiator Inc is a trusted name in the automotive cooling business. The company has helped radiator makers in North America and other places for a long time. Atlas Radiator Inc gives machines and solutions for both car and truck radiator making.

Product Range

Atlas Radiator Inc has many radiator making machines. They sell tube mills, fin forming machines, core assembly lines, and tank clinching equipment. These machines help make radiators for many kinds of cars and trucks. The company also sells tools and parts for fixing and keeping radiators working.

Strengths

Atlas Radiator Inc is known for good quality and customer service. They use strong materials and new technology in their machines. Their after-sales help includes training, spare parts, and technical support. Atlas Radiator Inc keeps up with new ideas like machine learning and data analytics. This helps them make better machines and services. Their global reach means they can help customers in many places.

Customer Insights

Customers pick Atlas Radiator Inc because the machines work well and the support is strong. Many buyers say the company answers fast and the staff is helpful. The machines get good reviews for being tough and easy to use. Customers also like the training and technical help they get. These things make customers happy and want to buy again.

Guangdong Faret Auto Radiator

Company Overview

Guangdong Faret Auto Radiator Co., Ltd. is a big name in the world radiator market. The company is well known in the industry. Guangdong Faret sells radiator making machines and parts to many countries, like Ghana and others.

Product Range

Guangdong Faret Auto Radiator has many machines and parts for making radiators. They have equipment for both car and truck radiators. Their products include core assembly, tank clinching, and testing machines. Guangdong Faret also has solutions for different car cooling systems.

Strengths

Guangdong Faret Auto Radiator is known for machines that work well and a strong supply chain. The company sells in many countries and keeps up with new trends. Guangdong Faret uses good materials in their machines, so they last long and work well. The company sells in over 24 countries, showing they are good at exporting.

Customer Insights

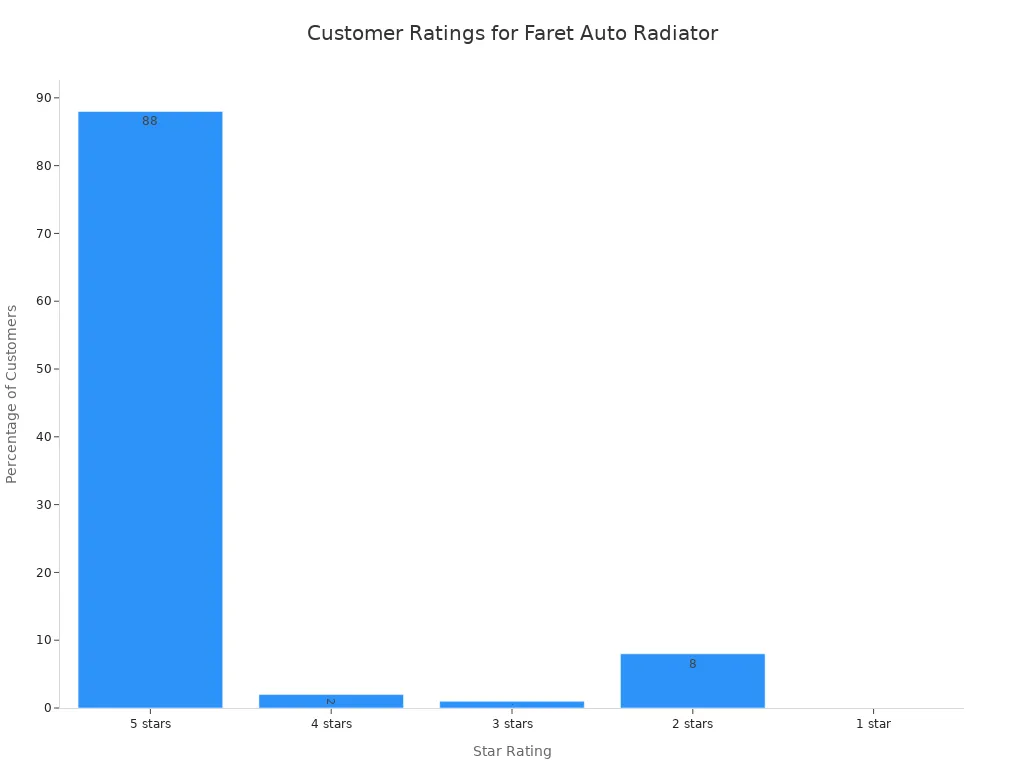

Most customers are very happy with Guangdong Faret Auto Radiator’s machines. Many give the company a 5-star rating, which means they trust the products and service.

| Star Rating | Percentage of Customers |

|---|---|

| 5 stars | 88% |

| 4 stars | 2% |

| 3 stars | 1% |

| 2 stars | 8% |

| 1 star | 0% |

Customers say the company gives good products and machines that work well. The high number of top ratings shows Guangdong Faret is trusted by radiator makers who want good cooling solutions.

Radiator Supply House

Company Overview

Radiator Supply House is a top maker and seller in the radiator business. The company has a big factory in the United States. It makes metal replacement radiators, steel tanks, and all aluminum radiators. Radiator Supply House helps many groups, like car, farm, building, and heavy machine companies. People know the company for being reliable and making good products.

Product Range

Radiator Supply House sells many cooling products. They have radiators, charge air coolers, and hydraulic coolers. The company also makes oil coolers and special products for unique needs. Customers can buy parts for semi-trucks, diesel motorhomes, garbage trucks, RVs, and fast cars. Radiator Supply House keeps lots of stock, so customers get what they need fast.

- Radiators for cars, trucks, and big machines

- Charge air coolers to help engines work better

- Hydraulic coolers for work and building jobs

- Special radiators made for different uses

Strengths

Radiator Supply House is great for many reasons:

- The company gives strong radiators and custom choices.

- It handles special orders and meets customer needs.

- Radiator Supply House is known for good service and quick work.

- The team helps with many jobs, from farms to race cars.

- The company keeps lots of products ready, so customers do not wait long.

Note: Radiator Supply House helps people keep their cooling systems working well with fast help and good products.

Customer Insights

Customers often say Radiator Supply House answers fast and has friendly workers. Many buyers talk about the good radiator making machine for cars and trucks. People like that the company can make special orders and send products on time. The company cares about happy customers and strong products, so people buy again. Customers trust Radiator Supply House for both normal and special cooling needs.

American Radiator

Company Overview

American Radiator has been in the radiator business for a long time. The company works in the United States and sells to people all over North America. American Radiator gives good cooling products for cars, trucks, and big machines. People trust the company because it always gives good service and products.

Product Range

American Radiator has many products for cars and big vehicles. They sell radiators, charge air coolers, and oil coolers. The company also has radiator making machine for cars and trucks, helping both small shops and big factories. American Radiator keeps parts for many kinds of vehicles, so customers find what they need.

- Radiators for cars, trucks, and buses

- Charge air coolers for diesel engines

- Oil coolers for work and business vehicles

- Radiator making machines for different jobs

Strengths

American Radiator has many good points:

- The company sells many products for lots of vehicles.

- It gives help and advice for setting up and fixing parts.

- American Radiator keeps lots of parts, so customers do not wait long.

- The team answers questions and helps customers fast.

Tip: American Radiator is a good pick for cooling needs because it has many products and strong support.

Customer Insights

Customers like American Radiator because the products work well and the staff knows a lot. Many buyers say it is easy to find new radiators and cooling parts. The company ships fast and gives good help, so people are happy. Customers often come back because they trust American Radiator’s quality and service.

Radiator Manufacturers: Comparative Analysis

Strengths and Weaknesses

Radiator makers want to know what makes each supplier different. The table below shows what each company is good at and where they have less information. It helps people see which supplier might be best for them.

| Company | Strengths | Weaknesses |

|---|---|---|

| DAG | Advanced automation; high precision; 24/7 support; full automation saves time and reduces errors; fast machines fitting many core sizes; OEM/ODM options; strong after-sales support | Warranty details only product-specific |

| Atlas Radiator Inc | Fast shipping for regular machines; spare parts always available; easy setup; training for new workers; good after-sales support | Custom machines may take longer to deliver |

| Radiator Supply House | Excellent customer service; quick turnaround time | Limited product specifications; no detailed warranty information |

| Guangdong Faret Auto Radiator | Wide export network; strong supply chain; high customer satisfaction | Not enough public details on weaknesses |

| American Radiator | Broad product range; reliable support; fast shipping | Not enough public details on weaknesses |

Note: Radiator makers should look at both strengths and weaknesses. This helps them pick the right supplier for their needs.

Unique Selling Points

Each supplier has something special that helps them stand out. DAG uses smart machines and high accuracy. This helps radiator makers get better cooling and fewer mistakes. Atlas Radiator Inc ships fast and their machines are easy to set up. This is good for companies that need quick help. Radiator Supply House is known for great customer service and fast orders. This keeps factories running without long waits. Guangdong Faret Auto Radiator sells to many countries and has happy customers. This means they are trusted in many places. American Radiator has lots of products and strong support. This helps many different radiator makers.

Suppliers in North America use light materials like aluminum. This helps car makers save gas and meet rules about pollution. Some companies use AI and machine learning to make better radiators. These new ideas help makers who want to improve their products.

Best Fit for Business Types

Radiator makers need different things based on their size and market. DAG is best for medium or big factories that want smart machines and strong cooling. Atlas Radiator Inc is good for companies that want fast shipping and easy training. Radiator Supply House is great for those who care about customer service and quick help. Guangdong Faret Auto Radiator is a good choice for makers who want a strong export partner. American Radiator is best for companies that need many products and strong support.

Tip: Pick a supplier whose strengths match your business needs. This helps you get the best results.

Choosing the Right Radiator Machine Supplier

Assessing Needs

Radiator makers need to know what their factory needs before picking a supplier. The machine should fit the size of the factory and help reach both today’s and tomorrow’s goals. Machines with lots of automation work faster, make fewer mistakes, and keep workers safer. It is good if the machine can handle different radiator core sizes, fin types, and materials like aluminum or copper. This lets the factory make many kinds of radiators.

A machine that can grow with the factory is important. This saves money in the long run. Machines that are accurate and use less energy help keep quality high and costs low. The new machine should work well with the equipment already in the factory. After-sales support is also important. Quick help, spare parts, and training keep the factory running.

Factories should think about how they will pay for the machine. Payment plans should fit the company’s budget and cash flow. Safety features like light curtains and two-hand buttons help keep workers safe. A good supplier has a strong reputation, a good warranty, and can make custom machines. These things make the machine more reliable and valuable.

A checklist for needs:

- Make sure the machine fits the factory and goals.

- Pick machines with lots of automation for speed and safety.

- Check if it works with different radiator sizes and materials.

- Choose machines that can grow with the factory.

- Look for accuracy and energy savings.

- Make sure it works with current equipment.

- Check after-sales help and training.

- Review payment plans and financing.

- Look for safety features.

- Check the supplier’s reputation, warranty, and custom options.

Evaluating Credentials

Factories should check each supplier’s background before buying. Certifications like ISO 9001 or IATF 16949 show the supplier follows strict rules for quality. These papers mean the supplier uses good steps and gives the same results every time. Factories should also look for suppliers who make radiators for many car types.

Custom machines are helpful for special needs. Suppliers who can change machines or make new ones help factories do special jobs. Factories should read the warranty carefully. A strong warranty protects against problems and shows the supplier trusts their own machines.

Good customer support is important too. Helpful teams answer questions and help with setup and repairs. Factories should check what other customers say about the supplier. Good reviews and a history of helping customers show the supplier can be trusted.

A table for checking credentials:

| Credential | Why It Matters |

|---|---|

| ISO/IATF Certification | Shows the supplier makes good products |

| Custom Solutions | Helps with special factory needs |

| Warranty Coverage | Protects if something goes wrong |

| Customer Support | Gives help with setup and repairs |

| Reputation | Shows if the supplier can be trusted |

Comparing Quotes

Looking at quotes from different suppliers helps factories get the best deal. Factories should not just look at the price. The quality of the materials is very important. Radiator tanks must handle heat and pressure. Factories should check if the supplier’s products are tested for pressure, DOT-certified, or ISO approved.

The machine must fit the radiators the factory wants to make. Reading reviews from other users helps check if the machine is easy to use and fits well. Warranty and customer support matter too. A supplier with good support and a strong warranty is more reliable.

Factories should use real reviews to compare how easy the machine is to install and how long it lasts. They should not pick just by price. The total cost includes repairs and how long the machine lasts. It is also important to check if spare parts and accessories are easy to get.

A step-by-step way to compare quotes:

- Check the quality of materials and certifications.

- Make sure the machine fits the radiators you want to make.

- Look at warranty and customer support.

- Read reviews about installation and how long the machine lasts.

- Think about the total cost, not just the price.

- Check if you can get spare parts and accessories easily.

Tip: When looking at quotes, think about long-term value and trust. The best supplier gives good quality, strong support, and custom machines that fit your business.

Site Visits and Demos

Factories often want to see machines in action before making a big purchase. A site visit gives buyers a chance to check the supplier’s workshop. They can watch how the team builds and tests machines. This step helps buyers see if the supplier can deliver custom machines and custom solutions that fit their needs.

During a site visit, buyers should look for these things:

- Clean and organized work areas

- Skilled workers who know how to build custom machines

- Machines that match the promised features

- Real examples of custom solutions in use

A demo lets buyers test the machine. The supplier runs the machine with real parts. Buyers can check if the machine makes the right products. They can ask questions and see how the machine handles custom jobs. This step helps buyers feel sure about the machine’s quality and the supplier’s skills.

Tip: Always ask for a live demo. This shows how the machine works with custom settings and different materials.

A checklist for site visits and demos:

- Watch the machine run with your own parts.

- Ask the team to show custom features.

- Check how easy it is to change settings.

- Test the machine’s speed and accuracy.

- Talk to workers about custom solutions and support.

Site visits and demos help buyers make smart choices. They see the supplier’s skills and learn how the team handles custom requests. This step builds trust and helps buyers pick the right partner for their factory.

Building Partnerships

A strong partnership with a supplier brings long-term value. Buyers should look for suppliers who want to grow together. A good supplier listens to feedback and offers custom support. They help with upgrades and new custom solutions as the factory grows.

Partnerships work best when both sides talk often. Buyers should share their goals and plans. The supplier can then suggest custom machines or new solutions. This teamwork leads to better products and faster problem-solving.

Key steps to build a good partnership:

- Set clear goals for custom projects

- Keep in touch with regular meetings

- Give feedback on custom machines and solutions

- Work together on new custom ideas

Note: A supplier who offers custom solutions and listens to feedback helps factories stay ahead in the market.

A table to track partnership progress:

| Partnership Step | What to Do |

|---|---|

| Set Goals | Define custom needs and solutions |

| Regular Meetings | Discuss progress and new custom ideas |

| Feedback | Share results and suggest improvements |

| Joint Development | Work on custom upgrades and new solutions |

A good partnership means more than just buying a machine. It means working together on custom projects and finding new solutions. This approach helps factories stay flexible and ready for change.

DAG, Atlas Radiator Inc, Guangdong Faret Auto Radiator, Radiator Supply House, and American Radiator are trusted suppliers in this field. Each company has its own special strengths and ways to help. Buyers need to look at what makes a supplier trustworthy and see if those strengths fit their business.

Check the comparison and checklist to help you pick the best supplier for your factory.

FAQ

What is a radiator making machine used for?

A radiator making machine helps factories make radiators for cars and trucks. The machine puts together parts like tanks and cores. It makes sure each radiator works well to cool engines.

How do suppliers ensure product quality?

Suppliers check their machines carefully and follow strict rules. They test each machine to make sure it does not leak and is strong. Many suppliers have certificates that show their machines are good quality.

Can these machines work with different radiator sizes?

Yes. Most machines can change to fit many radiator sizes. This lets radiator fan makers build radiators for small cars and big trucks.

What after-sales support do suppliers provide?

Suppliers give training, spare parts, and technical help. Many answer questions quickly. Some send engineers to help set up or fix machines.

How important is a radiator cooling fan in the system?

A radiator cooling fan pushes air through the radiator. This helps keep the engine from getting too hot. The fan and radiator work together to stop overheating.

How do buyers choose the right supplier?

Buyers look at the supplier’s reputation, certificates, and support. They compare machine features and prices. Visiting the site and reading reviews also help buyers pick the best one.

Do suppliers offer custom machines?

Many suppliers make machines for special needs. They can change settings or add new features. This helps factories reach their own production goals.