Introduction to Radiator Core Builder Machines

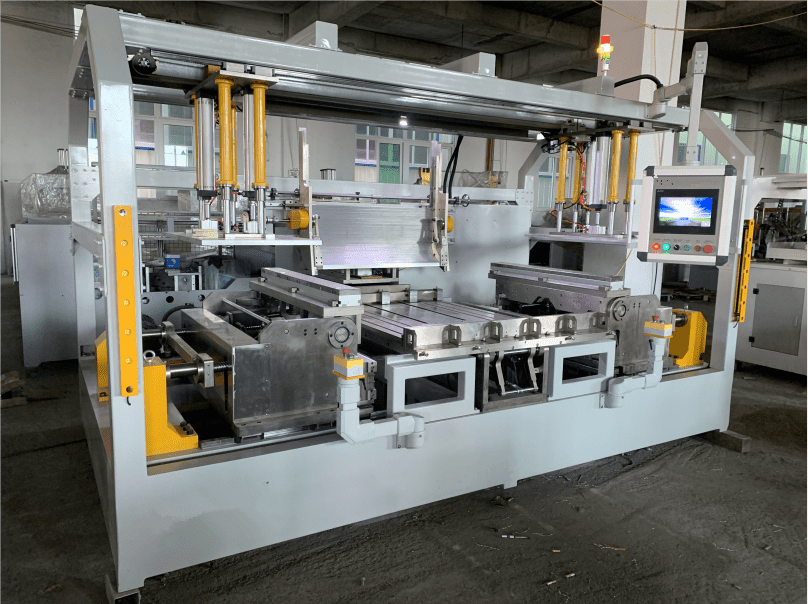

Radiator core builder machines are an integral part of the automotive manufacturing process. Through their meticulous engineering design and assembly, these machines have produced high-quality radiators. Their central role in the automotive industry cannot be overstated. It’s crucial to delve into the specifics that make these machines efficient and reliable.

The radiator core builder machine has the advantage of stable and reliable working performance. This essential attribute is the result of a combination of several unique features, each of which contributes to the overall efficiency and functionality of the machine. The advantage of stable and reliable working performance is seen in the machine’s ability to perform its tasks and in the quality of the resulting product.

This article will examine the radiator core builder machines in depth. We’ll explore their features, benefits, and working principles and understand why their performance is stable and reliable. We’ll also discuss the importance of easy operation, low noise, accurate positioning of flat tube centres, and even distribution of fins. Additionally, we’ll examine how the assembled condenser core has high assembling accuracy and a pleasing appearance, which ensures a better brazing effect in the brazing furnace.

Features and Advantages of Radiator Core Builder Machines

The radiator core builder machine has several features that enhance its functionality and make it a desirable component within the automotive industry. One of the standout features is its easy operation. This is a critical factor as it impacts the efficiency and productivity of the entire production process. Machines that are easy to operate reduce the chances of errors and mishaps, ensuring a smooth and uninterrupted workflow.

Another significant feature of the radiator core builder machine is the low noise it generates during operation. This can be a considerable advantage in a working environment, as high noise levels can disrupt concentration and, over time, even impact the workers’ health. The low noise feature also adds to the machine’s overall stability, making it a reliable tool in manufacturing.

Furthermore, the radiator core builder machine is known for accurately positioning flat tube centres. This precision is vital for producing high-quality radiators. Even distribution is another key feature that adds to the machine’s advantages. Even distribution ensures that the heat dissipation process in the radiator is efficient and effective.

Understanding the Working Performance of Radiator Core Builder Machines

Taking a closer look at the working performance of the radiator core builder machine, it becomes evident why these machines are so reliable and stable. The primary reason for this stability is the machine’s ability to perform consistently under various conditions. This consistency stems from the machine’s design, allowing for high operation precision.

The machine’s operation can be divided into several stages, each contributing to its overall performance. The first stage involves the accurate positioning of the flat tube centres. This process ensures that the tubes are aligned correctly, which is crucial for the subsequent stages of the operation.

Next comes the even distribution of fins. This process is carried out meticulously to ensure uniform heat dissipation across the radiator. The even distribution of fins also contributes to the finished product’s aesthetic appeal, making it more appealing to the end consumer.

Following this is the assembly of the condenser core. This process involves a high level of precision, as any errors at this stage can significantly impact the performance of the finished radiator. The high assembling accuracy of the radiator core builder machine ensures that this process is carried out flawlessly.

Finally, the entire assembly is subjected to brazing in the brazing furnace. This process is crucial, as it helps bind all the components together, providing the radiator with its final shape and form. The brazing process also impacts the appearance of the finished product, with an excellent brazing effect resulting in a more appealing final product.

The Role of Easy Operation in Radiator Core Builder Machines

Easy operation in radiator core builder machines is crucial for several reasons. First, it reduces the complexity of operating such machines, making it easier for operators to carry out their tasks. This reduced complexity not only enhances the efficiency of the production process but also reduces the chances of errors and mishaps.

Second, easy operation contributes to faster training of new operators. This is particularly beneficial in situations with a high staff turnover. With easy-to-operate machines, new operators can be brought up to speed quickly, reducing downtime and enhancing overall productivity.

Finally, easy operation reduces the mental and physical strain on the operators. Operating complex machinery can be stressful and demanding. However, this stress is significantly reduced with easy-to-operate machines like the radiator core builder machine, leading to better job satisfaction and improved worker health and safety.

The Importance of Low Noise in Radiator Core Builder Machines

Low noise is another critical feature of radiator core builder machines. High noise levels can be very disruptive in a working environment. They can interfere with communication, cause stress, and even lead to hearing loss over time. In contrast, low noise levels contribute to a more conducive working environment, enhancing productivity and worker wellbeing.

The low noise feature of radiator core builder machines is particularly beneficial in environments where multiple machines operate simultaneously. In such scenarios, the cumulative noise from all the machines can be high. However, low-noise machines like the radiator core builder can significantly reduce this cumulative noise.

Moreover, low noise contributes to the overall stability and reliability of the machine. High noise levels can sometimes indicate mechanical issues within the machine. Hence, a low-noise machine is likely to be more stable and reliable, reducing the need for frequent maintenance and repairs.

Accurate Positioning of Flat Tube Centers: A Key Factor in Radiator Core Builder Machines

Accurate positioning of flat tube centres is an essential feature of radiator core builder machines. This process ensures that the tubes are perfectly aligned, which is crucial for the subsequent stages of the operation.

The precision with which this process is carried out directly impacts the quality of the finished radiator. Inaccurate positioning of the flat tube centres can lead to uneven heat dissipation, resulting in a lower-quality product.

Moreover, accurately positioning flat tube centres enhances the machine’s overall efficiency. With each tube perfectly aligned, the machine can carry out its tasks more efficiently, reducing the time it takes to produce each radiator.

Even the Distribution of Fins in Radiator Core Builder Machines

The even distribution of fins in radiator core builder machines is another key feature contributing to the machine’s overall performance. The fins play a crucial role in the heat dissipation process in the radiator, so their distribution needs to be uniform across the entire radiator surface.

The even distribution of fins ensures efficient heat dissipation and contributes to the finished product’s aesthetic appeal. A radiator with evenly distributed fins is more likely to appeal to the end consumer, making it a more desirable product.

Moreover, the even distribution of fins enhances the overall stability and reliability of the machine. With each fin perfectly positioned, the machine can carry out its tasks more efficiently, reducing the time it takes to produce each radiator.

Assembled Condenser Core: High Assembling Accuracy

The assembled condenser core is another critical radiator core builder machine component. This process’s high accuracy ensures the condenser core is perfectly aligned and assembled. This precision is crucial, as any errors at this stage can significantly impact the performance of the finished radiator.

The meticulous design and engineering of the machine achieve high assembling accuracy. The machine is designed so that each component perfectly fits into its designated place, ensuring high precision during the assembly process.

Moreover, high assembling accuracy contributes to the overall stability and reliability of the machine. With each component perfectly assembled, the machine is less likely to encounter issues during operation, ensuring a smooth and uninterrupted production process.

The Impact of Good Appearance on the Brazing Effect

The appearance of the finished product is a critical factor that influences the brazing effect in the brazing furnace. A pleasing appearance is indicative of a well-assembled and high-quality product. This enhances the product’s appeal to the end consumer and impacts the radiator’s overall performance.

The excellent appearance of the finished product is primarily the result of the meticulous assembly process. Each component is perfectly positioned and assembled, resulting in a product that is not only functional but also aesthetically pleasing.

Moreover, the appearance of the finished product is directly linked to the brazing effect in the brazing furnace. A good brazing effect results in a well-bonded and cohesive product, which further enhances the product’s appearance.

Enhancing the Brazing Effect in the Brazing Furnace

The brazing effect in the brazing furnace is a crucial factor that influences the overall performance and quality of the finished radiator. The brazing process helps bind all the components together, providing the radiator with its final shape and form. Hence, enhancing the brazing effect in the brazing furnace can significantly improve the quality of the finished product.

One way to enhance the brazing effect is by ensuring high precision during the assembly process. With each component perfectly positioned and assembled, the brazing process can be carried out more efficiently, resulting in a better brazing effect.

Moreover, the brazing effect can be enhanced by maintaining optimal operating conditions within the furnace. This includes maintaining the correct temperature and pressure levels, which are critical for achieving an excellent brazing impact.

Conclusion: The Benefits of Stable and Reliable Performance in Radiator Core Builder Machines

In conclusion, radiator core builder machines’ stable and reliable performance is primarily the result of their unique features and meticulous design. These machines, with their easy operation, low noise, accurate positioning of flat tube centres, and even distribution of fins, offer numerous advantages that make them indispensable tools within the automotive industry.

Moreover, the high assembling accuracy and good appearance of the assembled condenser core further enhance the performance of these machines. These attributes ensure a better brazing effect in the brazing furnace and result in a high-quality and aesthetically pleasing finished product.

The radiator core builder machine is a shining example of engineering excellence in a world where efficiency, reliability, and quality are paramount. It is a testament to what can be achieved when the meticulous design is combined with innovative technology.

For those looking for a stable and reliable tool to enhance their radiator manufacturing process, the radiator core builder machine is undoubtedly a worthy consideration. Its superior performance and numerous advantages make it a valuable asset for any automotive manufacturing setup.