Radiator fin forming machines, a cornerstone of the automotive industry, have revolutionized the production of radiator fins. These machines are essential for manufacturing efficient heat exchangers, a vital component of modern vehicles. In this article, we delve into the intricacies of radiator fin-forming machines, shedding light on their working principles, features, and benefits.

Introduction to Radiator Fin Forming Machines

Radiator fin forming machines are specialized equipment used to produce radiator fins. These fins are integral parts of heat exchangers and are found in various applications, such as automotive radiators, air conditioners, and refrigeration units. The machines shape thin strips of metal, typically aluminium or copper, into specific fin patterns.

The Significance of Radiator Fins

Radiator fins play a crucial role in heat transfer. They increase the surface area exposed to the air, maximizing heat dissipation. A heat exchanger’s efficiency is significantly dependent on the design and quality of its fins, underlining the importance of advanced fin-forming machines in the production process.

Operational Principle of Radiator Fin Forming Machines

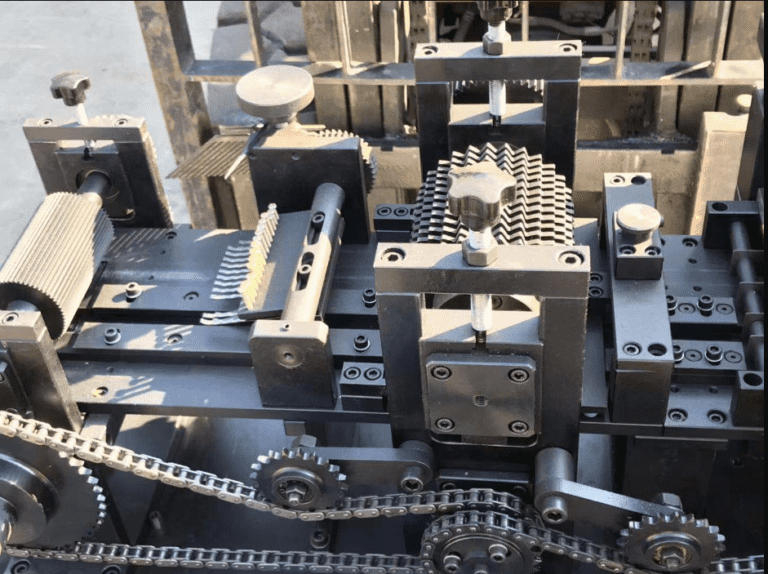

Radiator fin-forming machines operate on a rolling mechanism. They draw in a flat metal strip, apply lubricant, and pass it through a fin-forming unit. This unit, consisting of rollers, shapes the strip into the desired fin profile. The formed fins are then cut to the correct length, collected, and prepared for the following stages of heat exchanger assembly.

Key Features of Radiator Fin Forming Machines

Radiator fin-forming machines boast several noteworthy features:

High Precision and Speed

These machines are renowned for their high precision and speed. They ensure uniformity in fin height and pitch, even when operating at high speeds of up to 100 meters per minute. This combination of accuracy and speed boosts productivity and ensures high-quality output.

Versatility

A single fin-forming machine can produce various fin types by changing the fin mould. This includes straight fins, offset fins, corrugated fins, and more. Creating diverse fins on the same machine enhances its versatility and cost-effectiveness.

Advanced Control Systems

Fin-forming machines have advanced control systems, usually involving PLCs (Programmable Logic Controllers), AC servo controls, and touchscreen interfaces. These systems facilitate easy parameter setting and ensure reliable machine operation.

Lubrication Systems

Modern fin-forming machines often incorporate patented lubrication systems. These systems deliver lubricant in precise amounts, ensuring smooth fin forming and prolonging the life of the tooling. They also contribute to significant savings in lubricant consumption.

Benefits of Radiator Fin Forming Machines

The use of fin-forming machines brings several benefits:

Enhanced Product Quality

The high precision of these machines ensures consistent fin dimensions. This uniformity is crucial for the efficient operation of the heat exchanger. Additionally, the ability to produce various fin types allows for the design of heat exchangers optimized for specific applications.

Increased Productivity

With their high operating speeds and automation, fin-forming machines significantly boost productivity. They enable the rapid production of large volumes of fins, helping to meet high demand and reduce lead times.

Cost Savings

The versatility of fin-forming machines eliminates the need for separate machines for different fin types, consolidating capital investment and reducing floor space requirements. Also, using advanced lubrication systems minimizes lubricant consumption, resulting in further cost savings.

Conclusion

Radiator fin-forming machines are indispensable tools in the production of heat exchangers. Their high precision, speed, versatility, and advanced control and lubrication systems deliver superior quality fins, increased productivity, and significant cost savings. As technology progresses, these machines will continue to evolve, enhancing their capabilities and benefits.