Radiator Making Machine Manufacturer in China

DAG is a Chinese-certified manufacturer specializing in the design and manufacture of automotive radiator-making machines, such as Side Plate Auto-Forming Machines, Harmonica Pipe Straightening and cutting Machines, Collecting Pipe Auto-Punching-Forming Machines, Collecting Pipe Auto-Grooving Machines, and Automatic Tube-Bending Machines.

DAG provides high-quality radiator making machines to automobile manufacturing plants, auto parts factories, air conditioning manufacturing plants, and other industries. The equipment we design has the characteristics and advantages of excellent stability, long life, stylish and beautiful appearance, high precision, suitability for products of various specifications, high finished product qualification rate, high production capacity, and customer repurchase rate as high as 95%.

Radiator making machines come in many different features, designs, and sizes. They are suitable for oil coolers, radiators, air conditioning evaporators, condensers, etc. In addition to this, DAG can customize the machine to your required specifications. Your logo or custom labels can be printed on the machine.

If you need a radiator making machine for your business, you can select from our wide range of equipment below or contact us if you want a specific type of machine. Send us your inquiry today!

DAG Radiator Making Machine

The machine consists of a tube warehouse, fin transmission, flaring, fin inserting devices, etc. This machine, together with the fin-forming machine, automatically finishes the fin-insertion process. The length of the flat tube decides the quantity of fin inserting each time.

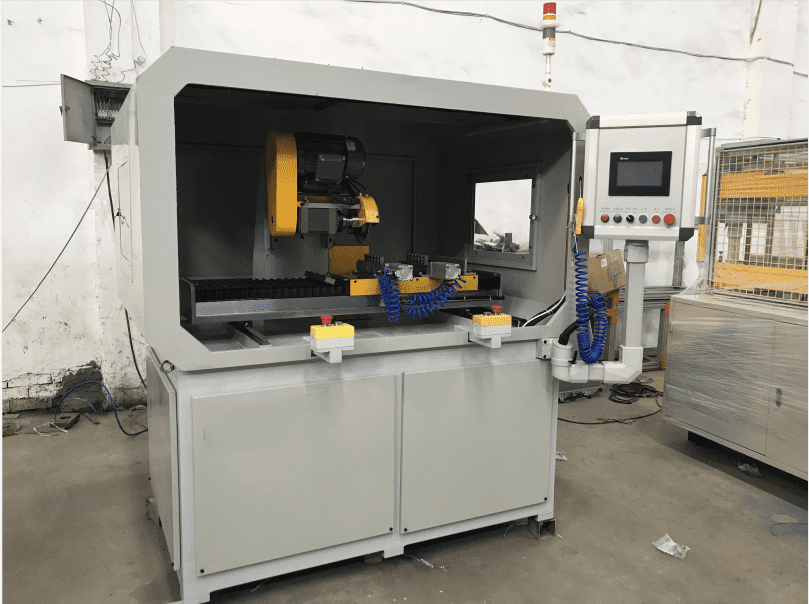

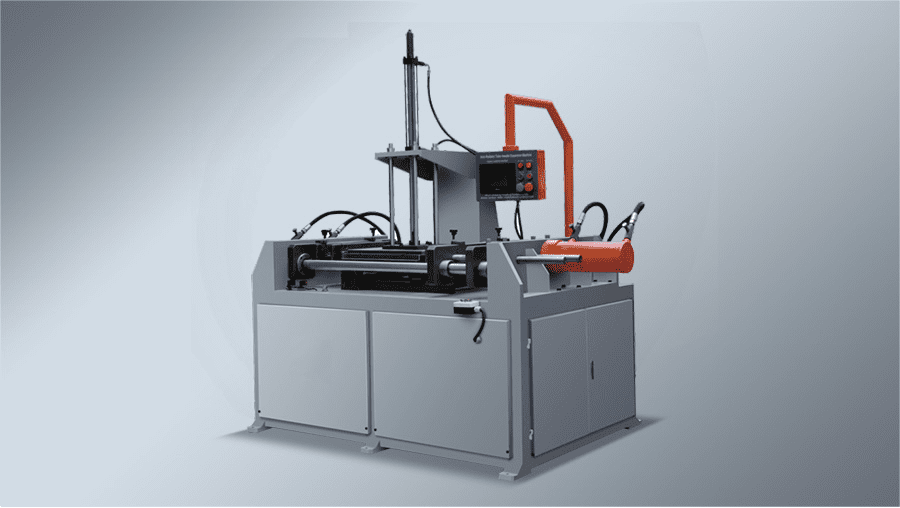

An automatic manifold pipe piercing machine punches manifold pipes at a fast, stable, and reliable speed. It can punch both round and D types of manifold pipes and make special dies for different pipe dimensions.

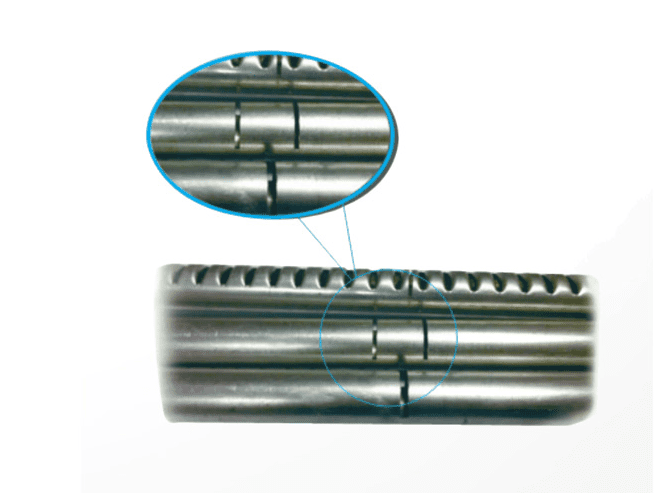

This is the dedicated equipment for manifold pipe baffle groove cutting. The positioning block, automatic slot, automatic groove, automatic retreat, high cutting positioning accuracy, fast speed, and smooth cutting surface lock the flow pipe.

The header pipe punching machine is necessary equipment for the parallel flow condenser production line. It is used to produce round or abnormal-shaped collecting pipes for parallel flow condensers.

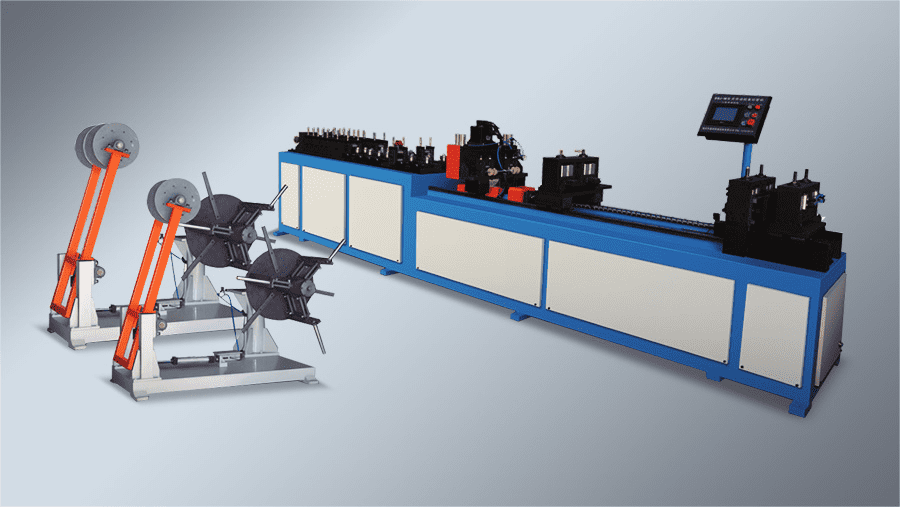

The machine can have the coiled strip go through a straightening device, edge forming, punching, pressing into an arc structure at both ends and cutting off automatically according to the dimensions per different types of tooling to make another side plate.

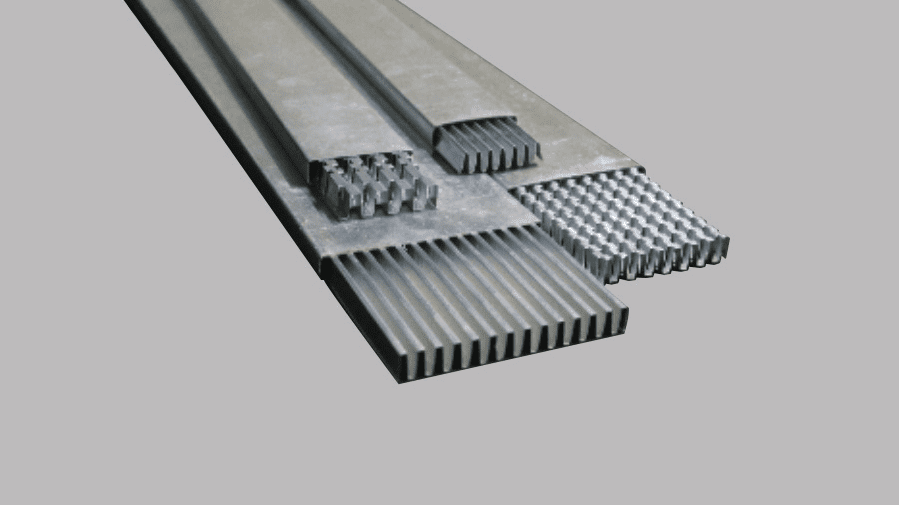

The flat tube plates (aluminum flat pipes) pass through the rolls, straight, bending, shrinking, and cutting off the formation tube-type bending pipe products. By replacing the flat pipes of different specifications of different specifications, the editing program is directly stored.

The whole machine is fully controlled, and the length and width of the flat pipe can be adjusted. The transmission part is the servo motor with high-precision screws, and the cutting method is cut off with a knife type or wire knife. A servo motor completes the shrinkage part, and the pipes of different specifications can be achieved by replacing the fast fixture.

The aluminum pipe expansion radiator machine is used to expand the aluminum pipe inside to form a tight contact between fins and pipes with the help of hydraulic force. The electrical control system relies on a PLC controller to control the expansion process. Both automatic and manual control modes are available.

Pipe expansion is an important step in making mechanical aluminum radiators. The expansion machine is included in the mechanical radiator-making machines, which could flare the pipe end and form a tight contact between the header and the aluminum pipe.

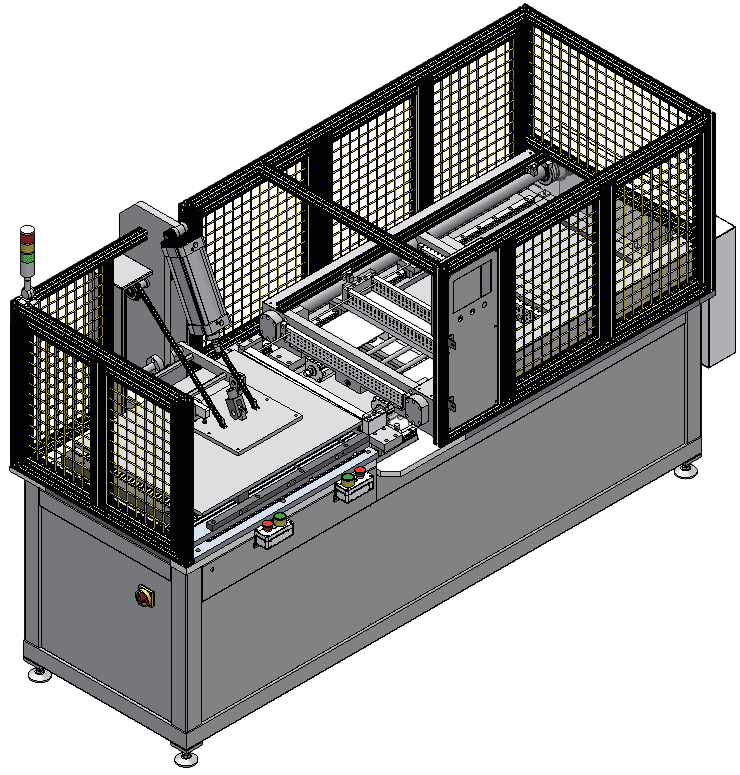

Radiator core wire bundling machine is a special equipment for automobile condensers, radiators and evaporator cores, which can prevent deformation during brazing and core bundling. The equipment is easy to operate, easy to adjust and highly efficient. It is suitable for small and medium batch continuous production.

This machine is a radiator sealing test equipment. It uses the air source pressure to pass through the sensor, digital display, fixture plug, time relay, and electromagnetic valve pressure difference test. It completes the pressure difference test in one working cycle to distinguish whether the radiator is leaking or not. Two products can be tested at one time.

This machine is the expansion joint equipment between the radiator fin and the heat pipe of the tube type radiator, through the whole operation process of the equipment: the cover plate pressing → expansion tube into → expansion tube back → cover plate rising → finish, so that the tube and fin of the tube type radiator reach the required requirements.

Choose DAG to Customize Your Machine Benefits

longevity

Stable performance, long life, high precision, simple operation, high safety performance, high production capacity, and high finished product qualification rate.

Customization

Provide OEM&ODM services and non-standard customization, and can design and customize machines according to customer product size specifications.

Technical Support

The technical team with more than ten years of experience is at your service at any time to help you solve problems, save you time and worry, and help your project grow rapidly.

7×24 service

The professional sales team provides pre- and after-sales services, solutions, operating training, machine maintenance, and repairs.

DAG has more than ten years of experience producing radiator making machines. Over the years, we have focused on designing and developing high-quality radiator making equipment to meet customer expectations.

Our experience, expert team, and advanced manufacturing equipment, such as a 3000W optical laser cutting machine, laser welding machine, CNC bending machine, and others, enable us to provide high-quality radiator manufacturing equipment and customized services.

If you want to customize radiator making machines, contact DAG!

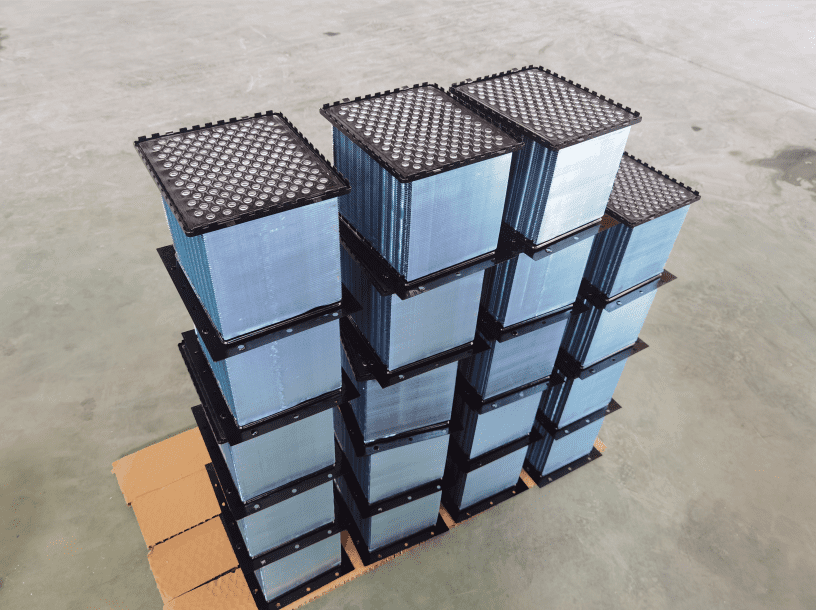

Finished Product Display