A radiator in car cooling systems is a crucial component that transfers heat away from the engine to maintain optimal temperature. In 2025, car owners face new challenges, especially with the rise of electric and hybrid vehicles that require advanced heat management solutions. Innovations in lightweight materials and smart sensors are enhancing radiator performance. Stricter emission regulations demand more efficient cooling systems. Understanding the importance of the radiator in car design and advancements in radiator making machines is essential for keeping vehicles safe and environmentally friendly.

Key Takeaways

- A car radiator cools the engine by moving heat to the air. This stops the engine from getting too hot and breaking. Taking care of the radiator with checks, cleaning, and new coolant helps the engine last longer. It also saves you money. New radiator designs use lighter materials and smart sensors. These help cool better and are better for the planet. Electric and hybrid cars need special cooling for batteries and electronics. This helps them work well and stay safe. Signs like steam, leaks, or a hot gauge mean radiator trouble. These problems need fast attention. Experts can fix hard radiator problems. They make sure the cooling system works well and lasts longer. Today, making radiators uses smart machines. This makes building them fast, exact, and high quality. Caring for your car radiator keeps your car safe and efficient. It also helps the planet in 2025 and later.

Radiator in Car

Engine Cooling System

The radiator in car is very important for cooling the engine. It helps keep the engine from getting too hot. The radiator in car works with other parts to move heat away. First, coolant takes heat from the engine block. The hot coolant goes through the upper hose into the radiator. Inside the radiator in car, tubes and fins help move heat from the coolant to the air. Air passes through the radiator, either from driving or a fan, and takes the heat away. The water pump keeps the coolant moving all the time. The thermostat lets coolant go to the radiator only when the engine is hot enough. Hoses connect all the parts so coolant can flow easily. The engine cooling systems also have a fan and an expansion tank to control pressure and coolant amount. All these parts must work together to stop the engine from overheating.

Tip: Check the radiator in car and the cooling system often to stop sudden problems.

Why Car Radiator Matters

The car radiator keeps the engine safe from harm. When the radiator in car works right, it keeps the engine at the right temperature. If the radiator breaks, the engine can get too hot. Overheating can bend cylinder heads, break gaskets, or even crack the engine block. These problems cost a lot to fix and can leave drivers stuck. The car radiator also helps the engine cooling systems save fuel and lower emissions. A good radiator in car helps drivers stay safe by lowering the chance of breakdowns and crashes from overheating. Signs of radiator trouble are a hot temperature gauge, steam under the hood, or coolant leaks. Drivers should watch for these signs to stop bigger issues.

- Key functions of the car radiator:

- Takes heat from the engine coolant.

- Moves heat to the air using tubes and fins.

- Works with the water pump, thermostat, and fan.

- Keeps the engine at a safe temperature.

- Stops engine damage and helps keep you safe.

Performance and Longevity

A radiator in car that is cared for helps the engine last longer. The radiator stops the engine from overheating by taking heat out of the coolant. Without a good radiator, the engine would get too hot and break. Doing things like flushing the coolant and checking for leaks keeps the radiator working well. Clean radiator fins and good hoses help the cooling system do its job. When the radiator in car is healthy, the engine works better, uses less gas, and lasts longer. Drivers who look after their car radiator save money and have safer cars.

- Benefits of a healthy radiator in car:

- Stops overheating when driving is hard.

- Lowers stress on engine parts.

- Helps save fuel by keeping the engine cool.

- Makes breakdowns and crashes less likely.

- Makes the car last longer.

Note: Easy things like checking coolant and cleaning the radiator help your car last longer.

How Does a Radiator Work

A car radiator is very important in the cooling system. It keeps the engine from getting too hot. The radiator uses coolant fluid to take heat away from the engine. This helps stop engine damage and keeps the car working well. Knowing how a radiator works helps drivers find problems early and keep their cars in good shape.

Main Components

A car radiator has many parts that help it work. Each part helps the cooling system do its job.

Tubes and Fins

Tubes move hot coolant fluid from the engine. Fins are attached to the tubes. The fins have a big surface area. Air blows over the fins and takes heat from the coolant fluid. Most radiators use aluminum for tubes and fins because it moves heat well. This design helps the cooling system get rid of heat fast.

Coolant Flow

Coolant fluid goes through the engine and radiator in a loop. The water pump pushes the coolant fluid through the engine block. The coolant fluid takes heat from the engine. It then moves through hoses to the radiator. The thermostat controls when coolant fluid goes into the radiator. When the engine is hot, the thermostat opens. The coolant fluid goes into the radiator, cools down, and goes back to the engine. This cycle keeps the engine at the right temperature.

Pressure Cap

The pressure cap is on top of the radiator. It keeps the cooling system closed tight. The cap holds pressure inside the system. This pressure makes the coolant fluid boil at a higher temperature. The cap also lets out extra pressure if it gets too high. This keeps the cooling system safe and working right.

Tip: Always check the pressure cap for cracks or leaks. A bad cap can make the cooling system lose pressure and overheat.

Heat Exchange Process

The heat exchange process shows how does a radiator work. The coolant fluid takes heat from the engine. It moves through the radiator tubes. The heat goes from the coolant fluid to the metal tubes and then to the fins. Air moves over the fins and takes the heat away. Fans help move air when the car is not moving fast. This cools the coolant fluid before it goes back to the engine. The cycle keeps going while the engine runs. This stops the engine from getting too hot.

Types of Car Radiators

Car radiators come in different types for different needs. Each type has a special design. The table below shows common radiator types, their features, and where they are used.

| Radiator Type | Design Characteristics | Impact on Cooling Efficiency | Typical Applications |

|---|---|---|---|

| Aluminum | Lightweight aluminum construction | Superior heat dissipation, corrosion resistance, lightweight | High-performance cars, racing, modern vehicles |

| Copper/Brass | Traditional metal with high thermal conductivity | Excellent heat transfer, durable, easier to repair | Classic cars, heavy-duty trucks, off-road |

| Crossflow | Coolant flows horizontally (side-to-side) | Improved heat transfer due to shorter coolant path, compact | Front-wheel-drive cars, sports cars, compact |

| Dual-Pass | Coolant passes through radiator twice | Increased cooling time and capacity, better for high heat | Sports cars, race cars, high-performance mods |

| Plastic/Aluminum | Aluminum core with plastic tanks | Balanced lightweight and cost-effective cooling | Most modern sedans, compact and mid-sized cars |

| Vertical Flow | Coolant flows vertically (top to bottom) | Effective in large engine bays, durable | Classic cars, trucks, rear-wheel-drive vehicles |

Most new cars use plastic-aluminum radiators. These radiators are light and cost less to make. High-performance cars often use all-aluminum radiators for better cooling. Heavy-duty vehicles may use copper radiators because they move heat well. Picking the right radiator type helps the cooling system work better and last longer.

Car Radiator in 2025

New Technologies

Engineers have made many new changes to cooling systems. Aluminum radiators are now used more than copper or brass ones. These radiators are lighter and move heat away faster. Some radiators use strong plastics and composites to last longer. These materials help the radiator handle heat better. Some companies mix metal and plastic to make radiators stronger and work better.

Smart radiators use AI to watch and change temperature all the time. They change cooling to match what the engine needs and the weather. This saves energy and helps the engine work well. Some radiators use special materials that change when heated to cool better. Modular and 3D-printed radiators can be made in different shapes. This can make them cheaper and create less waste. Companies like Marelli make special cooling parts for electric cars. These parts help cool batteries, charge faster, and let cars drive farther.

Note: Aluminum micro-channel radiators and graphene cooling systems are being made. These new ideas may move heat better and weigh less.

Environmental Impact

New cooling systems help cars hurt the environment less. Many radiators now use safe solder and green materials. Aluminum cores with plastic tanks make cars lighter. Lighter cars use less fuel and make less pollution. Electric fans that change speed help engines use less energy and pollute less.

Designers made radiators smaller and better. This helps hybrid and electric cars work well. Special coatings help radiators last longer and work better. Companies follow strict rules to protect the earth. These changes help keep the planet safe and meet green goals.

- Key environmental benefits:

- Cars weigh less

- Use less fuel

- Make less CO2

- Easier to recycle

Electric and Hybrid Cars

Electric and hybrid cars need special cooling systems. These cars must keep batteries, motors, and electronics cool. Coolants in electric cars cannot carry electricity. This keeps the car safe from shocks. Some cooling systems fit the battery shape and keep it cool everywhere.

Battery cooling must stay between 20°C and 40°C. This helps batteries last longer and work better. Electric cars often use liquid cooling because it works well. Sensors watch the temperature and change cooling as needed. Some systems warm batteries in cold weather to keep them working.

Tip: Check and care for cooling systems in electric and hybrid cars. This keeps the car safe and helps the battery last longer.

Common Problems

Overheating

Overheating is a problem many drivers face with their cooling systems. This often happens when the radiator gets clogged. Dirt and small bits can build up inside over time. These block the coolant from moving through the radiator. When coolant cannot flow, heat stays in the engine. The engine then gets hot very fast and parts can get damaged. Pistons and cylinder heads are at risk. Sometimes, parts break and cause overheating too. If the water pump stops working, coolant will not move. This makes the engine overheat quickly. A thermostat that will not open keeps coolant out of the radiator. Cooling fans that do not turn on mean less air moves through the radiator. This is worse in slow traffic. Not taking care of the car, like using old coolant or not cleaning the fins, makes overheating more likely. Checking and cleaning the system often helps stop overheating and keeps the engine safe.

Leaks and Corrosion

Leaks and corrosion are big problems for the cooling system. Coolant leaks leave bright puddles under the car. These puddles can be green, orange, or pink. The liquid smells sweet and feels slippery. Corrosion looks like rust or strange colors on the radiator or nearby parts. Cracked hoses or a broken radiator cap can also cause leaks. If coolant leaks out, the engine cannot stay cool. White smoke from the exhaust or hood can mean a leak inside. Hissing sounds from the radiator can mean a leak or a bad cap. Drivers might see bubbles or steam coming from the radiator. Corrosion makes the metal weak and leaks happen more often. If you need to add coolant a lot or the level drops fast, the radiator may be failing. Fixing leaks and corrosion early can save money and stop bigger problems.

Warning Signs

Knowing the warning signs of a bad radiator can save the engine. If the temperature gauge goes into the red, the cooling system is having trouble. Coolant leaks under the car show there may be damage. Steam from under the hood means coolant is hitting hot engine parts. Drivers may smell something sweet if coolant is leaking. Low coolant in the reservoir needs to be checked. Dashboard lights for engine temperature or low coolant should not be ignored. Strange sounds like hissing or gurgling can also mean trouble. Watching for these signs and getting help early can stop overheating and engine failure.

Tip: Check the cooling system often and fix problems fast. This helps stop overheating and makes the cooling system last longer.

Maintenance Tips

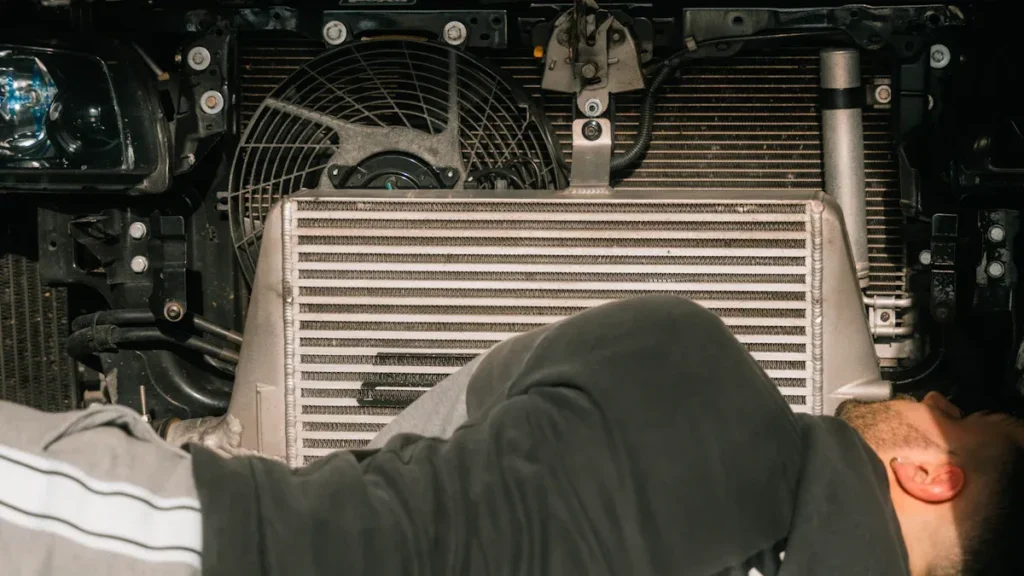

Inspection and Cleaning

Checking and cleaning the cooling system keeps it working well. Drivers should look for leaks, rust, or broken parts during checks. Finding problems early can stop bigger repairs later. Cleaning radiator fins with a soft brush or air gets rid of dirt and bugs. This helps air move through and cool the engine. Drivers need to check coolant fluid levels often and keep them right. They should also look at hoses for cracks or damage and change them if needed. Using a grille screen can block rocks or trash from hurting the radiator. Doing these things helps the cooling system work better.

Tip: Clean the radiator fins every few months and check for leaks after long trips or rough driving.

Inspection and Cleaning Checklist:

- Check for leaks, rust, or broken parts.

- Clean radiator fins so air can flow well.

- Look at coolant fluid level and fill if low.

- Check hoses and change if they are bad.

- Use a grille screen to protect the radiator.

Coolant Replacement

Coolant fluid wears out over time. Old coolant fluid cannot protect the engine as well. Drivers should flush and change coolant fluid when the car maker says. The right coolant fluid stops rust and buildup inside the radiator. Hot weather, heavy traffic, or towing can make coolant fluid wear out faster. Checking coolant fluid every month helps stop overheating. Fresh coolant fluid helps the radiator last longer and saves money on repairs.

- Change coolant fluid when the car maker says.

- Only use the right coolant fluid for your car.

- Check coolant fluid every month.

- Change coolant fluid more often in tough driving.

Note: New coolant fluid keeps the engine safe and helps the radiator last longer.

Professional Service

Some jobs need a mechanic’s help. Mechanics have special tools and know how to fix hard problems. They can test pressure, flush the system, and fix leaks drivers cannot fix at home. Getting help from a pro lowers the chance of mistakes or injury. Many shops give warranties for their work, which helps drivers feel safe. Professional service may cost more at first but can stop bigger problems later. For hard problems or if drivers are not sure, going to a trusted mechanic is best.

- Mechanics use special tools for good repairs.

- They do things like pressure tests and welding.

- Shops often give warranties for their work.

- Expert help makes the radiator and cooling system last longer.

Tip: Get help from a pro for leaks, overheating, or if you are not sure about any part of the cooling system.

Radiator Manufacturing

Modern Equipment

Radiator manufacturing has changed a lot over time. Old radiators used copper-brass and simple designs. In the 1970s, crossflow designs became popular. These helped cars with lower hoods and better cooling. Aluminum with louvered fins made radiators lighter but still good at moving heat. Plastic tanks on aluminum cores made radiators cheaper and lighter. Electric fans replaced belt-driven fans for better cooling. Now, radiators are often part of bigger cooling modules. These modules can have condensers and oil coolers. Active grille shutters help control airflow and save fuel. All these changes help new cars, including electric and hybrid models, stay cool.

Heat exchanger production now uses all-aluminum brazed designs. These designs make radiators lighter and better at moving heat. They also stop rust and leaks. This is important for electric and hybrid cars. These cars need strong cooling for batteries and electronics.

| Equipment Type | Function and Features |

|---|---|

| Core Benders | Bend radiator cores with precise radius control. |

| Formation Punch Press | Assemble radiator pieces with adjustable pressure for different models. |

| Core Cutters | Cut cores in automatic or manual modes, adaptable to size and speed. |

| Header Press Machines | Press radiator headers with adjustable tonnage and molds. |

| Leak Test Machines | Detect air pressure leaks to ensure radiator integrity. |

| Sealing Machines | Seal capillary tubes efficiently. |

| Robots | Automate tasks, reduce labor costs, and improve precision. |

| Car Radiator Core Assembling Machine | Assemble cores from various materials, including forming, spacing, and fin fitting. |

| Fin Stamping Machine | Produce different fin designs to improve heat dissipation. |

Modern machines help factories make radiators faster and with fewer mistakes. Automation and robots also lower labor costs and make better products.

DAG Radiator Making Machine

DAG is a top maker of radiator making machines. The company builds advanced equipment for making radiators and heat exchangers. DAG’s machines use smart PLC controls and servo motors for exact movement. Laser cutting and CNC bending help make strong and accurate parts. The machines work with both aluminum and copper. This lets them make many types of radiators.

Key Features

| Feature Category | DAG Radiator Making Machine Details |

|---|---|

| Technology | Smart PLC control, servo motors, laser cutting, CNC bending |

| Automation | Full automation, reduces labor time and errors |

| Material Compatibility | Supports aluminum and copper |

| Core Size Range | 150mm to 800mm |

| Speed | Up to 600mm per minute, steady performance, high accuracy |

| Customization | Branding and labeling options |

| User Feedback | Easy to use, low maintenance, 95% repurchase rate, 24/7 technical support |

| Certifications | ISO 9001 and CE certifications |

DAG machines use advanced controls and automation. They have robotics, IoT, and AI to keep heat steady and stop problems. Quality checks at every step help make sure each radiator is good. The machines save energy and do not take up much space. This makes them great for many factories.

Customization and Support

DAG gives strong customization and support to customers everywhere.

- DAG makes special solutions for each customer, including bulk and custom packaging.

- The company listens to what customers need, like factory setup and material choices, to suggest the best machines.

- DAG offers OEM and ODM services, free samples, and technical help.

- Customers can send requests and get answers fast, often in four hours.

- DAG helps customers worldwide with instructions, demos, software, and documents.

- The company promises on-time delivery and 100% good machine quality.

- After-sales help includes setup, training, spare parts, and warranty.

DAG’s focus on new ideas and customer care helps radiator factories build strong production lines. Their machines help make radiators that last longer and work better for electric and hybrid cars.

- New radiators help cars stay safe and work better. They use smart sensors and strong materials to control heat. Checking coolant and hoses often stops engine problems. This also saves money on repairs. Companies like DAG use machines and new materials to make better radiators. This helps cooling systems in the future. Car owners can read guides and expert articles online. These resources help them keep their cars running well.

FAQ

What does a car radiator do?

A car radiator takes heat away from the engine. It uses coolant and air to keep the engine cool. This stops the engine from getting too hot or breaking.

How often should drivers check the radiator?

Drivers need to look at the radiator and coolant every month. Checking often helps find leaks, rust, or low coolant early.

What are signs of a failing radiator?

Some signs are leaking coolant, steam under the hood, or a hot gauge. A sweet smell, rust, or hissing sounds can also mean trouble.

Can electric cars overheat without a radiator?

Electric cars must cool batteries and electronics. If they do not cool these parts, they can get too hot. Most electric cars use radiators or similar parts for cooling.

How long does a car radiator last?

Most radiators work for 8 to 10 years. How long they last depends on how you drive and care for them. Good care helps radiators last longer.

What is special about DAG radiator making machines?

DAG machines use smart controls and work by themselves. They make many radiator types and sizes. Factories use them for fast, careful, and steady work.

Why do modern cars use aluminum radiators?

Aluminum radiators are light and move heat fast. They do not rust and help cars use less gas. Most new cars use aluminum for better cooling.

How can drivers keep their radiator working well?

Drivers should change old coolant, clean fins, and check hoses. They need to fix leaks fast and get help for big problems. Taking care of the radiator keeps it strong.