Radiator fin machine technology in 2025 brings better speed and quality to factories. AI, IoT-enabled sensors, and new materials help radiator machine workers make products faster with less waste. Companies now want fully automatic lines. This is clear from the latest market changes:

| Region | CAGR (2023-2032) | Key Drivers |

|---|---|---|

| Asia Pacific | 7.2% | Automation, energy savings |

| North America | 5.5% | Innovation, efficiency |

| Europe | 4.8% | Regulatory standards |

DAG’s radiator fin forming machine is now the best for speed and performance. It shows how new radiator fin machine designs meet what factories need.

Key Takeaways

- Radiator fin machines in 2025 use AI, IoT, and automation. These tools help make fins faster and with less waste.

- New machines give exact control and quick changes. This helps factories make many fin types for different jobs.

- Advanced materials and 3D printing make fins stronger. They also help fins move heat better and allow custom designs.

- High-speed and multifunctional machines help factories make more fins. They can also switch products quickly.

- Quality control systems find problems early. This makes sure fins fit well and radiators last longer.

- Radiator fin technology helps many industries. These include automotive, electronics, energy, and HVAC. It gives better cooling solutions.

- There are some challenges like high costs and needing skilled workers. Material prices can also change. Training and smart spending help solve these problems.

- Future trends focus on smart manufacturing and green technology. Market growth will make radiator fin machines better and more eco-friendly.

Radiator Fin Machine Basics

What Is a Radiator Fin Machine

A radiator fin machine bends thin metal strips into fins. These fins are used in radiators and heat exchangers. The machine has rollers, driving parts, and folding tools. These parts help make different fin shapes. Workers put aluminum or copper coils into the machine. The rollers press and fold the metal into wavy, straight, or louvered fins. The machine has a PLC control system and servo feeding. It also has a touch screen that makes it easy to use. Some machines have special rollers for quick fin size changes. This helps factories save time and money. The machine can make fins from 0.07mm to 0.15mm thick. It can also make fins from 8mm to 200mm wide. Many factories use automatic machines. These connect to assembly lines for nonstop work.

Role in Manufacturing

The radiator fin machine is important for making radiators and heat exchangers. Fins give more surface area for heat to move out. This helps cool engines, electronics, and other things. The machine makes fins with exact height and pitch. This helps heat move better. Making fins takes several steps: 1. Rolling metal sheets to the right thickness. 2. Cutting sheets into thin strips. 3. Shaping strips to add more surface area. 4. Rolling strips into the final fin shape. 5. Cutting fins to the right length. 6. Putting fins and tubes together to make the radiator core. 7. Checking and finishing the product. Each step makes sure fins fit tightly with tubes. This is needed for good heat transfer. The radiator fin machine lets factories make many fin types. This helps them meet different needs.

Why Evolution Matters

Radiator fin machines have changed how factories make radiators. Long ago, copper and brass radiators were common. Copper moves heat well and does not rust easily. In the 1970s, factories started using aluminum. Aluminum made radiators lighter and saved fuel. This change needed new machines and ways to work. Today, smart machines use artificial intelligence and neural networks. These help make better fin designs. They help factories use less material but still cool well. For example, changing fin thickness or height can help cooling. But it might use more material. Modern machines let engineers test designs fast. They can find the best way to balance cooling and cost. This saves money and makes better products. Now, radiator fin machines help factories work faster and better.

Technology Advancements in 2025

AI and IoT Integration

Radiator fin machines in 2025 use new technology to work better. AI thermal systems help control cooling as the machine runs. These systems change settings to get the best results each time. IoT lets sensors collect data from all parts of the machine. This data helps workers watch the machine and know when to fix it. This means factories have less downtime and keep working well.

Many radiator makers now team up with tech companies to make smarter machines. These teams create new ideas for electric and hybrid cars. Battery cooling needs special radiators, and AI helps design fins for this job. These fins can cool without using liquid. IoT also lets engineers check machines from far away. This makes things easier for customers and helps save energy and cut waste.

Tip: Watching machines in real time and fixing them before they break saves money and keeps everything working well.

Automation and Robotics

Automation and robots have changed how radiator fin machines work. New lines use stations for each job, like cutting, shaping, welding, and finishing. Robotic arms and belts move parts from one station to the next. Sensors check each step to keep things on track.

Servo motors help shape fins very accurately. Visual systems help welding tools line up every joint. Data systems watch the machines and products all the time. If there is a problem, the system changes settings fast to keep quality high.

Automation means fewer people are needed to do the work. It also saves energy by reusing heat and cooling water. These changes help factories work better and meet new rules. Factories can now change to new radiator designs quickly, so they can make many types.

- Stations that can be changed make work easier.

- Servo motors and sensors help make things right.

- Automation saves energy and helps factories work better.

Advanced Materials

New materials are important for radiator fin machines. Factories now use composite materials to make fins light and strong. These materials still move heat well. Nanotechnology puts special coatings on fins. These coatings stop rust and help fins last longer.

Some machines use vibration to help move heat faster. The fins shake, which helps them cool better. This makes the machine work better, even if pressure goes up.

Factories use many fin shapes to get the best results. Shapes like corrugated, flat, sine wave, raised lance, and louvered all help move heat. Each shape is good for heat, strength, or easy cleaning. Common fin materials are aluminum, copper, and steel alloys. Each one is good for heat and fighting rust. Stainless steel, E-coat, Heresite, and CuNi are used when longer life or better work is needed.

Note: Picking the right material and fin shape helps factories make radiators for cars, electronics, and more.

3D Printing and Additive Manufacturing

3D printing is changing how radiator fins are made. Electrochemical Additive Manufacturing, or ECAM, uses electricity in a liquid to build copper fins slowly. It adds one atom at a time. This way, factories can make very detailed cooling parts. ECAM works at room temperature. It uses safer stuff than powder methods. Factories can use many printers at once. This helps them make more fins faster. Metal 3D printing lets engineers try new fin shapes. These new shapes give more surface area. This helps radiators cool better.

| Feature | Description |

|---|---|

| Material | Aluminum (AISi10Mg) made by metal 3D printing (SLM) |

| Design | Comb-shaped fins with more height and new shapes for better cooling |

| Heat Dissipation Surface Area | 1.5 times greater than traditional radiators |

| Heat Dissipation Volume | 0.4 times more than older designs |

| Weight | Less than 2000g, so the radiator stays compact |

| Additional Benefits | U-shaped grooves help air move and cool better; complex inside shapes lower costs |

Factories use 3D printing to make fin shapes that old machines cannot do. This technology lets them add fins or lattice patterns inside cooling ducts. These new designs help air move better. They keep engines cool. Factories can also make special fins for each car model. This makes cooling work better and last longer. Some companies use carbon fiber or glass fiber in their 3D printers. These materials make fins strong for hard jobs. Fast 3D printers with auto switchover help factories make more parts quickly.

Note: 3D printing helps factories make radiator fins that cool better, weigh less, and fit special needs.

Precision and Customization

Precision is important when making radiator fins. Factories use advanced technology to control every step. DAG’s radiator fin forming machines use PLC control and servo feeding. These systems help make fins with exact height and width. Some models keep height very close, from +0.03mm to -0.01mm. This means each fin fits just right in the radiator core.

Customization helps factories meet different customer needs. DAG’s machines can change fin rollers fast. Workers can switch from straight fins to wavy or louvered fins quickly. The machines let users set fin width from 8mm to 200mm. This helps factories make radiators for cars, trucks, and air conditioners. Touch screens make it easy to set up new jobs. Factories save time and waste by making only what they need.

- PLC control and servo feeding make exact fin shapes.

- Quick-change rollers help factories switch fin types.

- Custom settings let factories make fins for many uses.

This focus on precision and customization keeps quality high. It also lets factories respond fast to new market needs. Technology in 2025 gives factories more control and choices than ever before.

Radiator Fin Machine Features

High-Speed Production

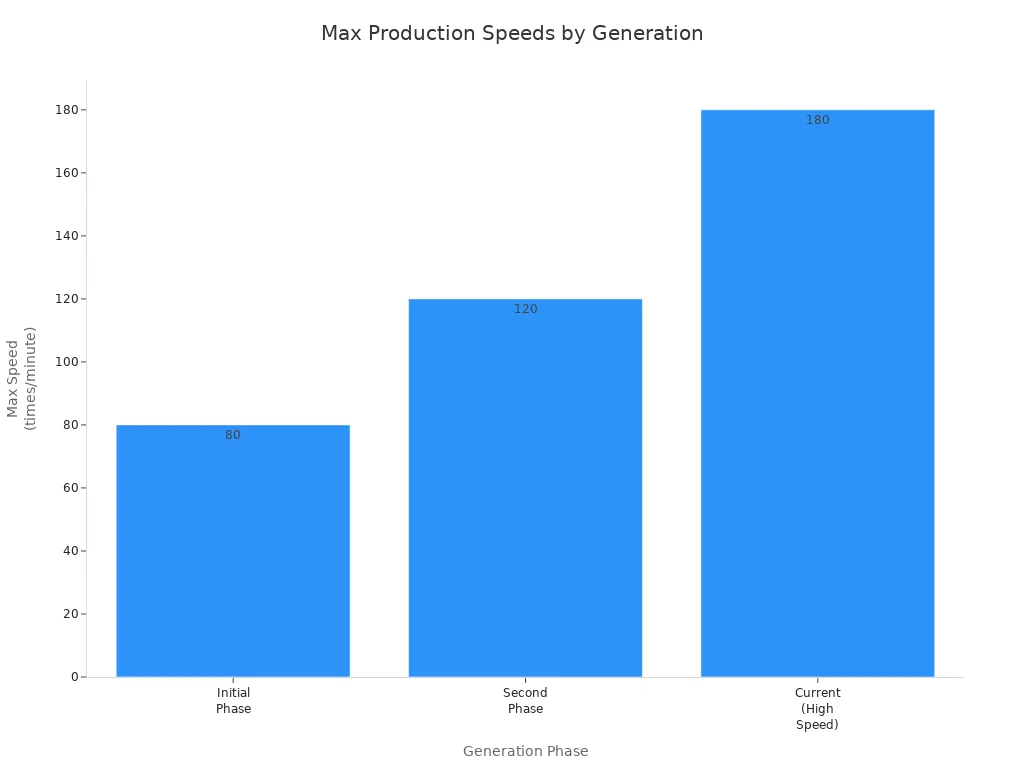

Radiator fin machines are much faster now. Old machines made 60 to 80 fins each minute. The next ones made up to 120 fins per minute. Today’s machines can make 180 fins every minute. This big speed boost helps factories make more radiators fast. Companies can fill big orders quickly and keep up with what people want.

| Generation Phase | Maximum Production Speed (times per minute) |

|---|---|

| Initial Phase | 60 – 80 |

| Second Phase | 80 – 120 |

| Current (High Speed) | 180 |

DAG’s radiator fin forming machines use strong motors and smart controls. These help the machine stay fast and keep making good fins. High-speed machines mean less waiting and more finished fins each day.

Multifunctional Design

Modern radiator fin machines do more than just make fins. They have many features that help factories work better and faster. These machines can change fin height, cut very exactly, and make many fin styles. Operators use touch screens to control the machine easily. Factories can make one to six rows of fins at once. This helps them make many kinds of radiators for cars, air conditioners, and electronics.

| Feature | Description and Benefit |

|---|---|

| Customizable Fin Height | Changes fin height up to 8mm for different needs, giving more choices. |

| Flat Fin Style Customization | Makes flat fins in many designs, so they work for different things. |

| High Precision Cutting | Cuts with 3-5mm accuracy, so there is less waste and fins are the same size. |

| High Production Speed | Up to 60 cut-off times per minute, so more fins get made. |

| Multi-row Production | Makes 1-6 rows of fins, so it fits many radiator types. |

| Touch Screen Operation | Easy controls mean fewer mistakes and faster setup. |

| Versatile Applications | Works for cars, HVAC, factories, and electronics, so it can be used in many places. |

These features help factories save time and money. They also make it easy to switch between different products. A multifunctional design lets companies stay ready for new jobs and changes.

Customization Capabilities

Customization is a big part of today’s radiator fin machines. Factories can quickly change fin types and sizes for new cooling needs. This helps them work for many industries, like cars, data centers, HVAC, and factories. Machines can make straight, wavy, louvered, or perforated fins. Adjustable rollers help fix tough cooling problems and meet special requests.

- Customization lets companies change fin types and sizes fast.

- Factories can make fins for many uses, like cars and data centers.

- Adjustable rollers help with special cooling needs.

- Flexible machines keep cooling working well for all jobs.

- Fast changes help companies stay ahead and work with other machines easily.

DAG’s machines help factories answer new needs quickly. This flexibility keeps them strong and ready for the future.

Quality Control

Quality control is very important for how well radiator fin machines work. Factories want every fin to be just right. DAG’s radiator fin forming machines use smart systems to check each part of the process.

Key Quality Control Features:

- PLC Control: The machine uses a PLC to control what it does. This system checks things like speed and pressure. Workers can set the numbers for each job.

- Servo Feeding: Servo motors move the metal strips very carefully. This keeps the fins the right height and width.

- Real-Time Sensors: Sensors watch the machine as it works. They find problems like jams or parts not lined up.

- Touch Screen Monitoring: Workers see what is happening on a screen. They can change settings quickly if needed.

Tip: Watching the machine in real time helps fix problems before they waste material.

Quality Control Table

| Feature | How It Helps Quality | Example Value/Result |

|---|---|---|

| Height Tolerance | Keeps fins the right size | +0.03mm to -0.01mm |

| Width Customization | Matches different products | 8mm to 200mm |

| Minimum Fin Thickness | Saves material, stays strong | As thin as 0.07mm |

| Automated Alarms | Stops errors early | Alerts for jams or faults |

DAG’s machines also have alarms that go off if something is wrong. These alarms stop the machine right away. This keeps bad fins from moving to the next step.

Quality Control Steps:

- The machine checks the metal strip before it starts.

- Sensors watch the rollers as they shape the fin.

- The system measures the height and width of each fin.

- The machine cuts the fins to the right length.

- Workers look at the finished fins to check for problems.

Factories follow these steps to make sure every fin works well in a radiator. Good quality control means radiators last longer and cool things better.

Note: Good quality control helps factories save money and makes customers trust them.

Impact on Radiators

Thermal Efficiency

Radiators today use new fin machine technology to help with heat. Engineers pick fin shapes like louvered, wavy, and pin. These shapes give more space for heat to move out. When coolant goes through the radiator, fins help take heat away from the engine. Louvered fins break up the air, so more heat leaves. Wavy fins fit more surface in a small spot, so cooling gets better. Pin fins have the most surface area and help cool engines in strong radiators.

Modern machines let factories change fin height, thickness, and space. For example, a 5mm tall fin with 1mm between and 0.5mm thick can lower heat resistance. This setup helps coolant move well and keeps engines safe. Engineers use computer models to test new fin ideas. They find that faster coolant flow makes fins work better. These changes help radiators move heat well and keep engines cool, even when working hard.

Note: The right fin shape and good coolant flow help radiators cool engines better.

Compact Design

Factories now make radiators small and work well. Fin machines cut fins to the right size. This lets engineers use new shapes like microchannel and serrated fins. These shapes help move heat without making radiators bigger. Some radiators use round or oval tubes that touch the fins. This lets more fins fit in less space. Laser welding helps make new tubes, like one-row twin tubes with two paths for coolant. These tubes cool engines better but keep radiators small.

A small design means radiators fit in tight engine spaces. Engineers use thin fin and tube materials, sometimes as thin as 0.002 inches. This makes radiators lighter and smaller but still cools well. B-tube technology uses a special tube shape to give about 15% more surface for heat. Multi-louvered fins line up to let more air move and cool better. These things help strong radiators cool engines in small spaces.

- Fins cut to the right size

- New fin shapes

- Thin materials

- New tube shapes

All these things help radiators save space and cool engines better.

Durability and Reliability

New fin machines help radiators last longer and work well. Engineers use all-aluminum for radiators. This metal does not rust and stands up to engine heat. The 5mm fin design moves up to 25% more heat. A bigger 2-row 42mm aluminum core cools even more. B-Tube technology adds about 15% more heat transfer. These changes make radiators stronger for engine cooling.

Factories test radiators to see if they last a long time. They shake the radiators to act like years of use. These tests show welds and joints stay strong, even when things get rough. Engineers look at the test results to find weak spots. They fix the design so it does not break. Radiators made with new fin machines pass these tests and last a long time.

Tip: All-aluminum radiators with new fin designs cool engines well and last longer in real life.

Radiators made this way help with heat, engine cooling, and last a long time for cars, trucks, and big engines.

Industry Impact

Automotive

Radiator fin machines have changed how cars are made. Engineers use aluminum alloys and new fin shapes. These help make radiators that save fuel. The machines let factories build radiators that keep engines cool. This works even when cars work hard. Advanced materials and electronic controls help cooling systems manage heat better.

- Light radiators help cars go faster and use less gas.

- Smart sensors and IoT let workers watch the radiator and engine live.

- Modular radiators and special coatings help radiators last longer.

- Factories use automation and AI to make more radiators with fewer errors.

Electric and hybrid cars need strong cooling for batteries and powertrains. Aluminum folded fin radiators work well for these cars. The radiator fin machine makes these parts small and light. This keeps engines and batteries at the right temperature. Factories can now build radiators that fit in tight spaces. These radiators still move coolant fast. This keeps engines safe and helps cars meet tough emission rules.

Note: More people want better cooling as EVs get popular and emission rules get stricter.

Electronics

The electronics industry needs radiator fin machines to stop devices from getting too hot. Rolled-formed fins give more space for heat to leave. These fins cool CPUs, power amps, solar gear, and LED lights. If heat stays, the device can break or stop working.

Aluminum skived fin radiator machines make fins for small spaces. These fins move heat away from devices fast. Engineers can change fin size and shape for each device. For example, a game console or laptop needs a small, light heat sink. It still must cool the processor. The radiator fin machine helps make these custom fins. In some systems, coolant moves through the fins and takes heat away. This keeps devices running well and protects engines in bigger machines.

Tip: Good cooling helps electronics last longer and work better.

Energy

Radiator fin machines are important in the energy field. Aluminum heat exchangers made by these machines move heat well. This helps save energy. Factories use these heat exchangers in power plants, renewable energy, and EV battery cooling.

- Pin fins and 3D printed fins help air move and cool faster.

- Factories use light, recyclable aluminum for easy-to-move heat exchangers.

- New materials like graphene-infused aluminum help heat exchangers work better.

- The radiator fin machine lets engineers make custom fins for each energy system.

Coolant moves through the fins and takes heat away from engines, batteries, or power electronics. This keeps power plant engines or solar batteries cool. As more people use renewable energy and EVs, better cooling is needed. Radiator fin machines help by making heat exchangers that work well and last long.

HVAC

Radiator fin machines play a big role in the HVAC industry. HVAC stands for heating, ventilation, and air conditioning. These systems keep buildings comfortable. They also protect equipment from getting too hot or too cold. Factories use radiator fin machines to make fins for heat exchangers in HVAC units. These fins help move heat away from the system. The machines shape metal strips into fins that fit tightly with tubes. This design lets air and coolant flow smoothly.

Engineers use radiator fin machines to make different fin shapes. Each shape helps the HVAC system work better. For example, louvered fins break up air flow. This helps the system cool or heat faster. Wavy fins add more surface area. This lets the coolant take away more heat. HVAC units need to work in many places, like homes, offices, and factories. The machines let engineers pick the right fin for each job.

The engine in an HVAC system needs to stay cool. If it gets too hot, the system can stop working. Radiator fin machines help by making fins that move heat away from the engine. The coolant flows through the tubes and touches the fins. The fins then move the heat into the air. This keeps the engine at the right temperature.

Factories want HVAC systems that use less energy. Radiator fin machines help by making fins that work with thin tubes. Thin tubes let the coolant move faster. This means the engine does not have to work as hard. The system uses less power and saves money. Engineers test different fin and tube setups. They look for the best way to move heat with the least energy.

Here is a table showing how radiator fin machines help HVAC systems:

| Feature | Benefit for HVAC Systems |

|---|---|

| Custom fin shapes | Better heat movement |

| Thin tube design | Faster coolant flow |

| High-speed production | More HVAC units in less time |

| Strong fin joints | Longer engine life |

Tip: Good fins help the coolant move heat away from the engine. This keeps HVAC systems running well in all seasons.

Radiator fin machines also help with new green HVAC designs. Engineers use lightweight fins and special coatings. These changes help the engine last longer and use less coolant. Factories can make custom fins for each building. This means every HVAC system can work its best.

Challenges and Opportunities

Adoption Barriers

Many factories have trouble getting new radiator fin machines. The machines cost a lot at first. This makes it hard for some companies to buy them. In places with less money, this is a bigger problem. The new machines have tricky systems. They need special care and fixing. Many workers do not know how to fix or take care of these machines.

The price of raw materials like aluminum and copper changes a lot. Sometimes, prices go up fast. This makes it hard for factories to plan how much they will spend. When prices rise, it costs more to make things. Factories must find ways to handle these changes.

There are many safety and quality rules to follow. Factories must do extra steps to keep workers safe and products good. Following all the rules takes more time and money. Some companies have trouble keeping up with new rules.

- High starting costs make it hard to get new machines, especially in places with less money.

- Tricky systems need special care and fixing.

- Changing prices for aluminum and copper make it cost more to make things.

- Tough safety and quality rules make work harder and cost more.

Tip: Companies that get ready for these problems can do better in the market.

Workforce Skills

New radiator fin machines need workers who know what to do. These machines use PLC controls, servo motors, and touch screens. Workers must learn how to set up, use, and fix these machines. Many factories need to teach their workers new things.

Training helps workers learn new skills. Some companies work with schools or training centers. They teach workers how to use the machines and fix problems. This training helps keep machines working well.

Workers with good skills can find problems early. They can fix small issues before they get big. This keeps the factory running and stops long breaks. Factories that train workers see better work and better products.

Note: Workers with good skills help factories get the most from new machines.

Investment

Spending money is important for getting new radiator fin machines. Companies must pay for new machines, training, and help services. It costs a lot at first, but the good things last a long time.

Many companies try to make spending less risky. Some use help from the government or get tax breaks to buy new machines. Others work with partners to share the cost. These ideas make it easier to get new machines.

Smart spending helps factories make more things and earn more money. Companies that buy new machines can make more products faster. They also use less energy and fewer materials. Over time, these savings help pay for the machines.

Investing in new radiator fin machines helps companies stay strong when things change.

Growth Potential

Radiator fin machine technology is growing in many fields. Experts think the plate fin radiator market will hit $4.6 billion by 2033. This is because new technology and more need for cooling systems are driving growth.

Many things help this growth:

- New radiator fin machines make cooling better and products smaller.

- More companies use these machines for electric cars, green energy, and data centers.

- Smart tools like IoT and AI help watch machines and check how they work.

- Asia-Pacific and North America are growing the fastest.

- New rules make companies use radiator parts that are better for the planet.

More people want energy-saving cooling in cars, planes, and factories. Electric cars need better cooling. The electric car market grows by over 22% each year. This means more advanced radiator fin machines are needed. Green energy projects also need small and strong radiator designs.

Here is a table with main growth drivers and challenges:

| Growth Drivers | Challenges |

|---|---|

| New technology for better efficiency | High starting costs |

| More use in new fields | Harder to make |

| Smart monitoring with IoT and AI | Changing prices for materials |

| Big demand in Asia-Pacific, N. America | Need to keep spending on research |

| Eco-friendly product needs | Tough competition and supply problems |

Companies like DAG help factories with these new needs. DAG’s radiator fin forming machines make fins fast and can change designs easily. Factories can make many fin types for different jobs. This helps them get more customers and try new markets.

New rules also change the market. Governments make rules for saving energy and recycling. Companies must follow these rules to keep selling. This means more need for machines that make green radiator parts.

There is a lot of competition. Companies must spend money on new ideas to keep up. They also need to watch out for supply problems and rising material costs. For example, aluminum prices have gone up by about 20% in two years.

Companies that buy new technology and teach their workers can grow faster and stay ahead.

Radiator fin machine technology will keep growing as more people need better cooling. Factories with advanced machines can work faster, save energy, and follow new rules. This growth will keep going through 2033 and after.

Future Trends

Smart Manufacturing

Smart manufacturing is changing how radiator fin machines are made. Companies use servo control systems and AI programs to make machines faster and more accurate. Some machines can go 120 meters each minute and keep a tight size limit of ±0.03mm. Dual servo motors help the machine run smoothly without shaking. Workers use a smart HMI screen to change settings fast. Pre-set programs let factories switch materials and thicknesses easily. IoT helps watch machines and fix them before they break. Modular designs let companies add or take away parts when needed. Factories say they make 40% more fins each day and spend 50% less on fixing machines. Fully automatic lines with fast fin machines and core builders need fewer workers and make more products. Servo pitch control lets factories change fin and tube layouts easily. These updates help the whole line work better and connect more.

Green Technology

Green technology helps make radiator fin machines cleaner for the planet. Studies show copper fins hurt the environment most. To fix this, companies use less copper or pick better materials like aluminum, carbon fiber, or bio-based composites. These new materials are lighter and easy to recycle. Factories recycle old radiators and use recycled aluminum to save energy. Many use solar or wind power to run their machines. Engineers follow eco-design rules like ISO 14006 to use less material and make greener products. CAD and CFD tools help design fins that work well and use less metal. Smart sensors watch machine health and help save power. Companies also follow new rules to be open and eco-friendly. These steps make factories work better and help the earth.

Note: Green technology helps companies give customers eco-friendly products and follow tough rules.

Market Expansion

The radiator fin machine market is growing in many places and jobs. Asia Pacific is growing fastest, with China and India building more factories and roads. The market there could reach $3.8 billion by 2032. North America and Europe are also strong because of strict rules and big needs in cars, planes, and power plants. New fields like green energy, ships, trains, and food factories now use advanced radiator fin machines.

Railways are growing fast, with a $1.5 billion market in 2025 and a 6% yearly growth. Companies use lighter materials and better cooling for these new jobs. Western Europe leads in new ideas and accuracy. Southern and Eastern Europe grow because costs are lower and workers have good skills. Nordic countries care about the planet and use new high-tech systems early. Both OEM and aftermarket sales help the market grow. OEMs add better cooling, and aftermarket sales go up for repairs and new parts.

Tip: Market growth brings new chances for better work, more connections, and new ideas in radiator fin machine technology.

Radiator fin machine technology in 2025 makes factories work differently. Companies can make things faster and with better quality. They also waste less material. DAG is a leader because it uses smart controls and automation. DAG also has special aluminum brazing ovens.

- DAG uses vacuum and continuous brazing ovens. These ovens make strong and clean joints.

- Smart controls and AI help stop mistakes and save energy.

- Customization and digital tools help make better products.

DAG works hard to bring new ideas and keep high standards. This helps shape the future of radiator manufacturing.

FAQ

What types of fins can DAG’s radiator fin forming machines produce?

DAG’s machines can make many fin types. They make straight, wavy, louvered, serrated, and perforated fins. These fins are used in radiators, condensers, and heat exchangers. Many industries use these fins for cooling.

How does PLC control improve radiator fin production?

PLC control lets workers set what the machine does. This system keeps fin size right and lowers mistakes. It also helps workers change settings fast.

Can DAG’s machines handle both aluminum and copper materials?

Yes. DAG’s machines work with both aluminum and copper strips. This helps factories make fins for different cooling needs.

What is the minimum fin thickness DAG’s machines can achieve?

DAG’s machines can make fins as thin as 0.07mm. Thin fins use less material and help radiators cool better.

How do IoT sensors help in radiator fin manufacturing?

IoT sensors gather data from the machine. They warn workers about problems and help stop breakdowns. This keeps the factory running smoothly.

Why is high-speed production important for radiator fin machines?

High-speed production means factories make more fins quickly. This helps companies fill big orders and meet what customers want.

How does DAG support customers after installation?

DAG gives technical help and free advice. Their team helps with setup, training, and fixing problems. This support keeps machines working well.

Tip: Doing regular maintenance and training helps factories get the best results from their radiator fin machines.