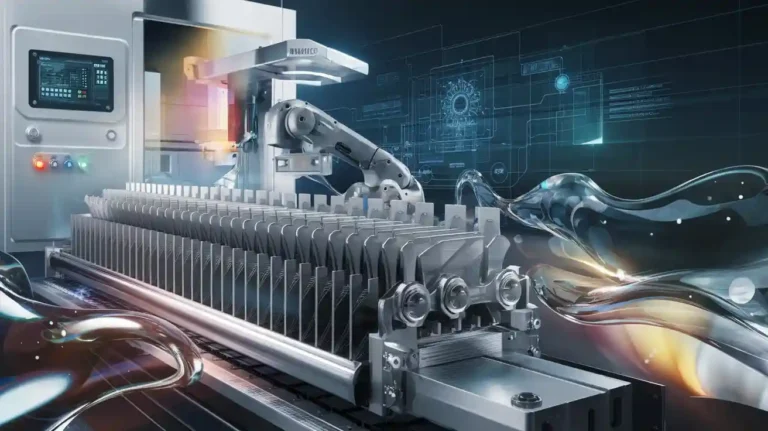

Radiator fin forming machine technology in 2025 changes how car radiators are made. Automation, AI, and IoT help at every step. DAG is a leader with new radiator ideas that make things faster and better. Smart sensors and CAD tools help the radiator machine make good fins for car radiator systems and HVAC. Real-time data helps machines work better and last longer. New aluminum alloys and coatings help the planet. The Plate Fin Radiator Market will grow a lot because more people want car radiators and smart radiator ideas. These changes show how technology and quality will shape radiator machines and car radiator products in the future.

Companies using advanced radiator machine systems, like the Advanced Aluminum Fin Forming Machine, Aluminum Fin Forming Machine, and Fin Rolling Machine For Radiator, get better quality and longer-lasting radiators.

Key Takeaways

- AI and IoT help radiator fin machines work smarter. They stop breakdowns and cut down on waste. Automation makes production faster and easier for fewer workers. Workers can run complex machine lines without trouble. New materials like copper-brass alloys and titanium make radiators stronger. These materials also help radiators move heat better. Precision forming tools make sure fins are the right size. The tools also give fins smooth edges for better quality. Smart controls and sensors help machines use less energy. They also help cut metal waste and save money. Robots and PLC systems make machines more accurate. They let workers switch between fin types quickly. DAG’s machines help many industries by making radiator fins fast. The fins are flexible and reliable. Following safety, environmental, and quality rules is important. It helps companies avoid trouble and grow.

Innovations in 2025

AI Integration

AI is changing how radiator fin machines work in 2025. Companies use AI and machine learning to make these machines smarter. The machines have sensors that gather data while making fins. AI checks this data right away. It can guess when a machine might break down. This helps stop problems before they happen and keeps the machines running. AI can also change machine settings by itself to keep the fins good. This means less waste and saves money.

- AI helps keep radiator production steady and smooth.

- Sensors and smart controls let the machine change quickly during fast work.

- AI and IoT sensors share data to help control the whole factory.

- Automation and robots, with AI, make radiator machine cells that work by themselves. These cells help stop mistakes and make the same thing every time.

- AI helps companies use less energy and be more green.

DAG uses these AI tools in its Advanced Aluminum Fin Forming Machine and Fin Rolling Machine For Radiator. These machines show how new ideas in 2025 make better fins and lower costs.

IoT Connectivity

IoT connectivity is very important for radiator fin machines in 2025. These sensors collect and send data to a main control system. The system uses this data to watch temperature, pressure, and speed. Workers can see this on smart screens. They can make quick choices to keep things working well.

IoT sensors also help people check the machines from far away. Engineers can look at the radiator machine from any place. If something goes wrong, the system sends a warning. This helps stop long breaks and keeps car radiator work going. IoT also helps companies follow green rules by watching energy and waste.

DAG’s Aluminum Fin Forming Machine uses IoT sensors for smart control and fast work. This tech helps make special fins and fits different radiator factories.

Automation Advances

Automation in 2025 makes radiator fin machines faster and easier to use. New radiator fin forming machines use PLCs, servo motors, and touch screens. These things let the machines work fast with fewer people. One or two workers can run the whole line. The machines do many jobs like decoiling, roll forming, pressing, welding, cutting, and stacking. This means less work for people and fewer mistakes.

Automation also lets workers change fin sizes and shapes fast. The radiator fin machine keeps the fins good and waste low. Some machines can make up to 280 meters of fins each minute. DAG’s radiator fin forming machines use these automation tools with smart sensors and strong controls. This gives companies more choices and control.

The market for new radiator fin machines is growing fast. The world market was USD 1.2 billion in 2024 and could be USD 2.5 billion by 2033. The growth rate is about 6-9% each year. More electric cars, data centers, and better HVAC systems are making the market bigger. Companies want radiator machines that work fast, have smart controls, and can make special fins.

| Aspect | Details |

|---|---|

| Market Growth Rate (Global) | CAGR of about 6-9.1% between 2024 and 2033 |

| Market Size (2024) | USD 1.2 Billion |

| Market Size Projection (2033) | USD 2.5 Billion |

| Key Demand Drivers | Electric vehicles, data centers, HVAC upgrades, green energy, smart infrastructure |

| Technology Drivers | AI, IoT, automation, sustainability, aluminum recyclability |

DAG’s radiator fin forming machine line, like the Advanced Aluminum Fin Forming Machine and Fin Rolling Machine For Radiator, meets these new needs. These machines help with fast work, smart sensors, and strong controls. They help companies stay ahead in 2025 with good radiator ideas and lots of choices.

Precision Forming

Precision forming is a big trend for radiator fin machines in 2025. Companies use special calibration and CNC tools to shape fins very accurately. This helps them meet tough quality rules and make every radiator the same.

- Digital controls and careful calibration keep size mistakes tiny, less than 0.02 mm.

- The rollers can be changed, so one machine makes many fin shapes and sizes.

- Workers can pick fin thickness from 0.07 to 0.08 mm and width from 8 to 200 mm.

- These machines work with both aluminum and copper, giving more choices.

- CNC tools and grinding make roller blades that cut clean, with no rough edges.

- Lubrication systems spray oil by themselves, keeping roller molds cool and safe.

- The machine can adjust tension on its own, so it works with hard or soft materials.

- Modular molds let workers swap rollers fast, making it easy to change styles.

- Mechanical cut-off keeps every fin the same length, with cuts accurate within 3-5 mm.

- Some machines can make up to six rows of fins at once, so they work faster.

These features help make better radiators and speed up production. Companies get fins with smooth edges, sharp cuts, and steady sizes. Some machines make fins at 120 meters per minute, and others reach 300 meters per minute. Quick mold changes and strong machines mean less waiting time. DAG’s Advanced Aluminum Fin Forming Machine, Aluminum Fin Forming Machine, and Fin Rolling Machine For Radiator use these precision forming tools to help factories keep up in 2025.

Precision forming gives companies the flexibility and custom options they need to stay ahead in the busy radiator market.

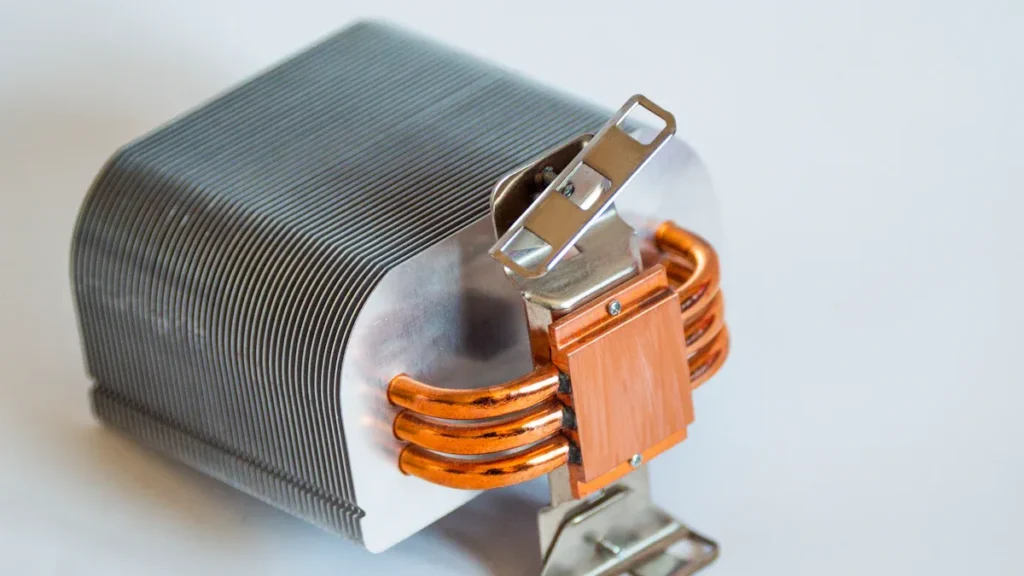

New Materials

In 2025, radiator fin machines use new materials to get better results. Companies pick new alloys and metals to make radiators stronger and better at moving heat. Anneal-resistant copper-brass alloys are popular because they stay strong and conduct heat well after brazing. These alloys have about 92% conductivity after brazing and do not have cadmium, so they are safer for the planet. Laser welding helps make new copper-brass radiator shapes, like one-row “twin” tubes. These new shapes make radiators lighter and stronger than old two-row types.

Titanium alloys are also getting noticed in 2025. Titanium fins are lighter than aluminum or copper fins but move heat better and last longer. Aluminum is still a cheap choice for many radiators, but titanium is best for strength and heat transfer. These new materials help radiator fin machines meet the needs of new cars, HVAC, and electronics.

Old radiator fins used aluminum, copper, bronze, and steel. Aluminum is light and cheap. Copper and bronze move heat better but cost and weigh more. Steel is cheap but can rust. Now, new copper-brass and titanium give companies more ways to make radiators that work better.

DAG’s radiator fin forming machines can use both old and new materials. This lets factories make high-quality fins for many uses. Being able to use different materials helps companies keep up with changing needs in 2025.

Radiator Fin Forming Machine Performance

Speed and Accuracy

Radiator fin machines in 2025 are faster and more accurate than before. Some machines can make up to 600 millimeters of fins every minute. This helps factories keep up with more orders. DAG’s Advanced Aluminum Fin Forming Machine and Fin Rolling Machine For Radiator are good examples. These machines use servo feeding and PLC controls to keep each fin the same. They cut fins very carefully, with mistakes less than 0.02 millimeters. This makes sure radiators work well and last longer. Quality control checks each step, so workers find problems early. Fast and accurate machines help companies save time and money while making great radiator products.

Versatility

Versatility is very important for radiator fin machines today. Companies want machines that can make many types of fins and use different materials. Modern machines can make straight, flat, serrated, perforated, wavy, and louvered fins. They work with both aluminum and copper, even special kinds like aluminum foil 3003-H16 and copper H62. Interchangeable rollers let workers change fin models fast. One machine can do many jobs in the factory. Operators can change fin thickness from 0.07 to 0.15 millimeters and width from 8 to 200 millimeters. Advanced Aluminum Fin Forming Machine and Aluminum Fin Forming Machine have these flexible features. The combined-width roller design helps keep the line moving. These machines are used in cars, HVAC, and factories, showing they can do a lot.

- Modern radiator fin machines make many fin shapes.

- Machines work with both aluminum and copper.

- Interchangeable rollers help change models fast.

- Adjustable thickness and width fit many radiator types.

- Machines are used in cars and HVAC around the world.

Energy Efficiency

Energy efficiency is now a big goal for radiator fin machine makers. New machines use special fin designs, like thin roll bond flat heat pipe fins. These new fins lower thermal resistance by over 23 percent and cut temperature rise by about 10 degrees Celsius compared to old aluminum fins. This helps radiators cool faster and use less energy. Automation, robots, and smart controls like IoT and AI help machines run fast but save power. Real-time monitoring lets machines change settings to stop waste and keep quality high. DAG’s Fin Rolling Machine For Radiator and other models use these tools to be efficient and reliable. Factories now use lighter and smaller machines that use less energy but still work well. Quality certifications like ISO 9001 and CE show these machines are safe and efficient. Energy-saving radiator fin machines help companies spend less and support green goals.

Energy-efficient radiator fin machines help factories save money and protect the planet while keeping good quality.

Waste Reduction

Waste reduction is a big goal for radiator machine makers in 2025. Companies want to make more fins but use less metal. New radiator fin forming machines help factories do this. Machines like the Advanced Aluminum Fin Forming Machine and Aluminum Fin Forming Machine use smart controls and sensors. These tools watch each step and change settings right away. This keeps the process smooth and cuts down on wasted metal. The machines help the line move fast.

Factories use the Fin Rolling Machine For Radiator to make many fin shapes. It works fast and does not waste much. The machine can change models quickly. This means less waiting and fewer leftover pieces. When workers swap rollers, the machine remembers the last settings. This saves time and keeps the fins good. The machine uses sharp cutting tools. These tools make sure every fin is the right size. This means fewer bad parts get thrown away.

Smart radiator machines help companies save money and help the planet by making less waste.

Many companies now use digital tracking systems. These systems count all the metal that goes in the machine. They also count how many fins come out. If the numbers do not match, the system sends a warning. Workers can fix problems fast. This keeps the line moving and the fins good. The machines also use special oiling systems. These put just enough oil on the rollers. This stops the metal from sticking and keeps waste low.

Here are some ways new radiator fin forming machines cut waste:

- Automatic sensors check each fin’s thickness.

- The machine stops if it finds a mistake, so workers can fix it fast.

- Quick-change rollers let the machine switch jobs without wasting metal.

- Digital controls keep the speed and quality steady.

- Real-time data helps workers find problems before they get worse.

A table below shows how cutting waste links to speed and quality:

| Feature | Impact on Waste | Impact on Speed | Impact on Quality |

|---|---|---|---|

| Smart Sensors | Less scrap | Faster checks | Better fins |

| Quick-Change Rollers | Less downtime | Higher speed | Consistent size |

| Digital Tracking | Early fixes | No slowdowns | Fewer mistakes |

| Precise Cutting Tools | Exact sizes | Fast cutting | Smooth edges |

Factories that use the Advanced Aluminum Fin Forming Machine or Fin Rolling Machine For Radiator waste less and work faster. These machines help companies meet tough quality rules. They also help the planet by using less metal and energy. Cutting waste, while keeping speed and quality high, gives companies a big advantage in the market.

Automation in Production

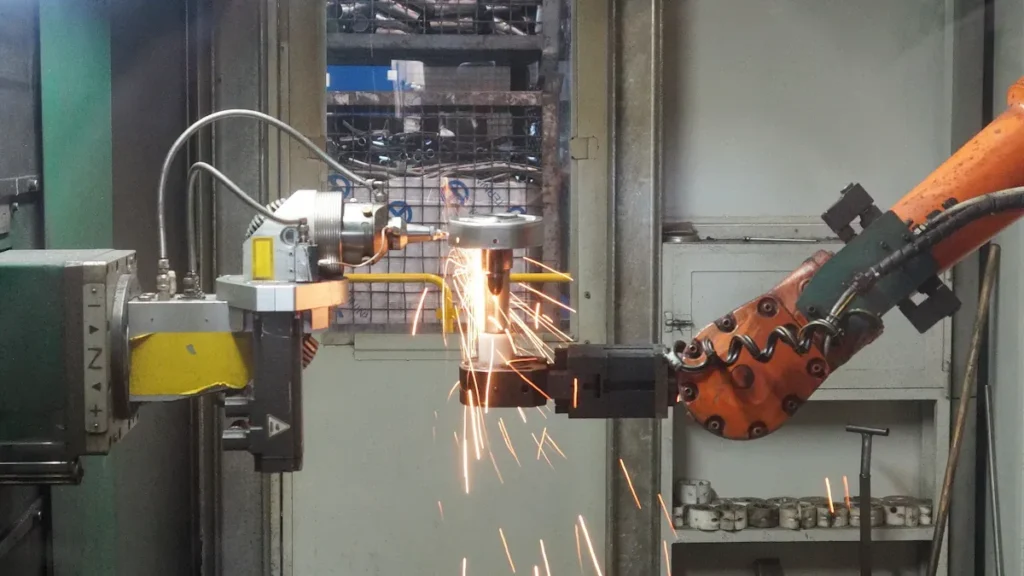

Robotic Systems

Robotic systems are now very important in making radiator fins. Robots lift heavy metal strips and move them through each step. They use smart sensors to check where each fin is and its shape. If something is wrong, the sensors tell the robot to fix it fast. Robots can stack, cut, and line up fins with great care. This helps stop mistakes and keeps the work going quickly. In many factories, robots and smart controls work together to keep everything running well. The Advanced Aluminum Fin Forming Machine uses robot arms and sensors to make things faster and safer. Robots also help make more than one row of fins at the same time. This lets factories make more fins in less time.

PLC and Servo Control

PLC and servo control systems help radiator fin forming machines work with care and change easily. It is like the machine’s brain. Workers use touch screens to set up each job. The PLC changes speed, pressure, and other things to fit the fin type. Servo motors move the metal strips very carefully. They keep the fins the right height and width, sometimes as close as +0.03mm to -0.01mm. Sensors watch the work and send data to the PLC right away. If a sensor finds a problem, the PLC can stop the machine fast. This stops bad fins from moving on. Quick-change rollers and special settings let workers switch between straight, wavy, or louvered fins. The Aluminum Fin Forming Machine and Fin Rolling Machine For Radiator use these smart controls. These systems help factories make many fin shapes and sizes without wasting time or metal.

- PLC control lets workers adjust machine settings very carefully.

- Servo feeding moves metal strips in the right way.

- Real-time sensors and touch screens help with quick changes and checks.

- Alarms and auto stops keep the product good.

Automated Changeovers

Automated changeovers help radiator machines switch jobs faster. Before, workers took a long time to change from one fin type to another. Now, smart controls and sensors help the machine remember each job’s settings. Workers pick a new fin model on the touch screen. The machine changes rollers, speed, and pressure by itself. This saves time and stops mistakes. The Advanced Aluminum Fin Forming Machine can switch between different fin widths and shapes quickly. Sensors check each step to make sure the change works well. Automated changeovers also help make more than one row of fins at once. Factories can do many jobs at the same time and meet more customer needs. Smart controls and sensors keep everything working smoothly and fast.

Automation uses robots, PLC, servo systems, and smart controls to help radiator fin forming machines work with high accuracy, change easily, and run well. These new tools help companies stay ahead in a fast-changing market.

Industry Applications

Automotive

Radiator fin forming machines are important in making car parts. They help build radiator fins that keep engines cool. Most car radiators use aluminum or copper fins. These fins move heat away from the engine. DAG’s machines, like the Advanced Aluminum Fin Forming Machine and Fin Rolling Machine For Radiator, help car factories make fins quickly all over the world.

Car makers want machines that are fast and make fins the right size. These machines can cut up to 60 fins every minute. They keep each fin close to the right size, with only a small difference of ±0.1mm. This helps every car radiator pass tough quality checks. The machines can make louver and serrated fins, which are used in car radiators and intercoolers. Fin heights go from 5mm to 8mm, and the pitch can be set between 6.5mm and 10mm. These choices let car companies design cooling for many car types.

Workers use touch screens to set up the radiator machine. This makes the job easier and helps stop mistakes.

DAG’s machines use roller forming to keep fins the same every time. They work with both 220V and 380V power, using motors from 1.5 tons to 22KW. This mix of power and speed helps car factories fill big orders. The machines can use both aluminum and copper, so they fit new car technology needs.

HVAC

Radiator fin forming machines also help make parts for HVAC systems. These systems move heat in and out of buildings. DAG’s Aluminum Fin Forming Machine and Fin Rolling Machine For Radiator help HVAC companies make many fin types. These fins are used in air conditioners, heat exchangers, and chillers.

HVAC companies need machines that can make different fin shapes and sizes. The machines can switch between straight, wavy, and louvered fins. This lets HVAC makers build radiators for homes, offices, and factories. The machines work with both aluminum and copper, so companies can pick the best material for each job. Fast changeover features help factories fill orders quickly.

| Feature | Benefit for HVAC Systems |

|---|---|

| Multiple fin types | Fits many HVAC designs |

| Fast production | Meets high demand |

| Easy changeover | Quick switch between jobs |

| Material flexibility | Aluminum or copper options |

DAG helps HVAC makers everywhere with good machines and support. This help lets companies keep up with new building needs.

Electronics

Electronics need to stay cool to work well. Radiator fin forming machines help make small, exact fins for electronics. These fins go into radiators that cool computers, servers, and power supplies. DAG’s machines can make very thin fins with tight spaces. This helps electronics makers build small cooling systems.

Electronics companies use the Advanced Aluminum Fin Forming Machine to make fins for heat sinks and micro radiators. The machines can work with thin aluminum or copper sheets. They cut fins with smooth edges and the right size. This keeps electronic parts safe from getting too hot.

Many electronics factories use DAG’s machines because they are easy to set up and make good fins.

DAG’s customers include electronics makers who need fast, flexible, and accurate radiator machines. These machines help keep computers and devices cool and safe.

Energy

Radiator fin forming machines are important in the energy field. Power plants use these machines to make fins for cooling big machines. These radiators help keep generators and turbines cool. If machines get too hot, they can break or stop. The energy industry needs strong cooling to keep things working.

Aluminum fins are used a lot in energy jobs. They make cooling systems lighter and save energy. Aluminum is easy to recycle, which helps the planet. Many companies pick aluminum fins to use less fuel and help the environment. The Advanced Aluminum Fin Forming Machine and Aluminum Fin Forming Machine from DAG help make these fins fast and well.

Factories use radiator machines to make fins for many energy machines. These machines shape fins with different patterns and sizes. The right fin design helps move heat away quickly. Engineers check airflow and fin direction to get the best cooling. Special coatings on fins help stop rust, so radiators last longer.

Smart radiator machines now have sensors and microcontrollers. These tools show how well the cooling system works right away. Workers can see if a radiator needs fixing before it breaks. This helps stop long breaks and saves money.

Some important things for radiator fins in energy are:

- How well they move heat

- How much energy they use

- How long they last when hot

- How well they fight rust

- How they fit different machines

Power plants use finned tube radiators to keep machines cool. The Fin Rolling Machine For Radiator helps make these fins very carefully. Factories can use aluminum or copper, depending on what they need. New aluminum alloys are stronger and handle heat better, so they are good for tough jobs.

Energy companies want smarter and greener radiators now. AI helps fix problems before they happen and makes cooling better. Modular radiator systems make it easy to fix or change parts. More companies want radiator parts that are good for the planet and can be recycled.

DAG helps energy companies everywhere. Their radiator machines meet high quality and efficiency rules. No matter if it is for a car or a power plant, DAG’s machines give good results for the energy world.

Challenges and Solutions

Investment Costs

Many companies think new radiator machines cost a lot at first. Machines like the Advanced Aluminum Fin Forming Machine or Fin Rolling Machine For Radiator need more money than old ones. These machines have automation, sensors, and smart controls. The higher price is because they work faster and make better fins. Companies worry if they will get their money back. They want to know if the new machine will save money later. Modern machines help by making less waste and using less energy. They also need fewer workers. These savings can help pay for the machine over time. Some suppliers, like DAG, let companies pay in parts and give help with setup. This makes it easier to start using new machines without big money risks.

Tip: Companies should look at all costs, not just the price. Think about saving energy, easy fixes, and how fast the machine works.

Workforce Skills

Workers need more skills to use new radiator fin forming machines. Old machines were simple and easy to use. New machines, like the Aluminum Fin Forming Machine, use PLCs, servo motors, and touch screens. Workers must know how to set up and watch the controls. They also need to fix small problems and do simple repairs. DAG helps companies by training workers. They give help with setup, technical support, and full training classes. This makes sure workers use the machines safely and well. Companies should check if their workers have the right skills before buying a new machine. Picking the right machine for the team helps stop mistakes and keeps work going.

| Machine Type | Required Workforce Skills | Training Programs and Support Available |

|---|---|---|

| Manual | Basic skills; follow simple step-by-step instructions | Setup and training support from DAG for easy assembly start |

| Semiautomatic | Technical skills; operate PLC systems; adjust machine settings | Technical help and training from DAG to optimize production |

| Automatic | Advanced skills; operate automation systems; perform maintenance | Comprehensive training and technical support from DAG |

System Integration

It can be hard to make new radiator machines work with other factory machines. New machines must connect with things like conveyors, stackers, and quality check stations. Factories need to link the controls so all machines share data and work together. If machines cannot talk to each other, work can slow down or stop. DAG makes its machines easy to fit into many factory lines. The Advanced Aluminum Fin Forming Machine and Fin Rolling Machine For Radiator use open control systems. These systems help connect with other machines and factory software. Engineers use control panels to set up links and watch the whole line. This helps factories keep work smooth and find problems early.

Note: Good system integration makes better products, less waiting, and helps companies fill orders faster.

Compliance

Companies using new radiator machine technology must follow many rules. These rules keep workers safe and help the environment. In 2025, more countries make strict rules for factory machines. The rules cover safety, energy use, and pollution. Every radiator machine, like the Advanced Aluminum Fin Forming Machine or Aluminum Fin Forming Machine, must meet these rules before use.

Many factories have trouble with compliance. They must check if machines have safety guards and emergency stops. Factories also need to make sure machines do not waste energy or make too much noise. Some countries want special labels or certificates for each Fin Rolling Machine For Radiator. These certificates show the machine passed safety and quality tests.

Tip: Always ask for certificates and test reports before buying a new radiator machine.

Factories must also follow rules about materials. Some places ban certain chemicals or metals. For example, many countries do not allow cadmium in radiator fins. The Advanced Aluminum Fin Forming Machine and Aluminum Fin Forming Machine can use safe materials like aluminum and copper. This helps companies follow local and world rules.

A table below shows some common compliance areas for radiator machines:

| Compliance Area | What Factories Need to Do |

|---|---|

| Safety | Use guards, alarms, and emergency stops |

| Energy Efficiency | Pick machines with low power use |

| Environmental Rules | Avoid banned metals and chemicals |

| Noise Control | Check machine noise levels |

| Certification | Get CE, ISO, or local certificates |

Working with trusted suppliers makes compliance easier. DAG gives support with documents and training. Their machines, like the Fin Rolling Machine For Radiator, come with test reports and safety features. DAG also helps with setup and teaches workers how to use the machines safely.

Companies should train workers on safety and compliance. They should keep records of all checks and repairs. Regular checks help find problems early. This keeps the factory safe and helps avoid fines.

Note: Following new rules helps companies avoid delays and extra costs. Good compliance also builds trust with customers.

By picking machines that meet high standards, companies can focus on making good radiator fins. Compliance is not just about rules. It helps factories work better and keeps everyone safe.

Future Trends

Digital Twins

Digital twins are changing how factories use radiator machines in 2025. A digital twin is a computer copy of a real machine. Engineers use this copy to try new ideas before changing the real machine. They can test different settings or materials on the digital twin. This helps them find problems early and fix them without stopping work.

Factories use digital twins to watch the Advanced Aluminum Fin Forming Machine and Aluminum Fin Forming Machine as they run. The digital twin gets data from sensors on the real machine. It shows how the machine works and tells when it might need repairs. This helps the radiator machine last longer and lets companies plan for fixes.

Digital twins also help workers learn. Workers can practice on the computer copy before using the real machine. This makes learning safer and faster. More factories use digital twins in 2025 and see better results and fewer mistakes. This trend will keep growing as technology gets better.

Digital twins help companies save time, lower costs, and make better products. They are an important part of new radiator machine technology.

Composite Materials

Composite materials are a big trend for radiator fin forming machines in 2025. These materials mix metals with other things to make fins lighter and stronger. Factories use the Fin Rolling Machine For Radiator to shape these new materials into special fins.

Engineers use nanofluids, like Al2O3 nanoparticles in Ethylene Glycol and water, with aluminum alloy fins. This mix helps radiators move heat faster. Companies can make radiators smaller and lighter but still cool well. CFD modeling shows radiator machines must work with these new materials and shapes.

New fin shapes, like triangle fins, use less material but move more heat. CFD analysis shows these fins have better heat flow and work better than old fins. Radiator fin forming machines now make complex shapes that save weight and cool better.

Louvered fins are also improved. By changing the angle and pitch, engineers make fins that cool more and fit in small spaces. CFD simulations show these changes help radiators work better and use less material. Radiator machines must shape these tricky and different fins.

Some designs add conduction fin parts that touch the panel. This helps move heat faster. Using a Water-Ethylene Glycol coolant mix helps too. CFD modeling finds these changes make radiators work better. Radiator fin forming machines now shape more complex fins for better cooling.

Composite materials and new fin shapes are changing radiator machine technology. Factories using these trends make better products for 2025.

Market Growth

The market for radiator fin forming machines is growing fast in 2025. More companies want machines with the newest technology and trends. The need comes from car, HVAC, electronics, and energy companies. These groups need better cooling for new products.

Reports say the world market for radiator machines could reach USD 2.5 billion by 2033. The growth stays strong because more people want electric cars, data centers, and smart buildings. Companies look for machines like the Advanced Aluminum Fin Forming Machine and Aluminum Fin Forming Machine to meet these needs.

New rules make factories use machines that save energy and cut waste. Companies want radiator machines that make many fin types and use new materials. The Fin Rolling Machine For Radiator helps factories keep up with these trends.

Experts see more changes coming. Digital twins, composite materials, and smart controls will lead the way. Companies that follow these trends will stay ahead in 2025 and after.

The future for radiator machine technology looks good. Market growth and new trends will change how factories work and what they make.

Sustainability

Sustainability is a big trend for radiator machine technology in 2025. Companies want to help the planet and make better choices. They try to use less energy and make less waste. They also pick materials that are safe for people and nature. These ideas change how factories use machines like the Advanced Aluminum Fin Forming Machine and Aluminum Fin Forming Machine.

In 2025, many factories use recycled aluminum and copper for radiator fins. This saves natural resources and keeps pollution lower. The Fin Rolling Machine For Radiator uses thin metal sheets, so less metal is wasted. Engineers make these machines use just enough oil and power. This helps save energy and money while protecting the earth.

Experts think green manufacturing will be a top trend in 2025. Companies that follow these ideas can meet new rules and get more customers.

Factories use smart controls to check how much energy each radiator machine uses. These controls help workers find ways to save power. For example, the Advanced Aluminum Fin Forming Machine can turn off some parts when not needed. This step saves energy and helps the factory reach green goals.

A table below shows how new radiator machine features help with sustainability in 2025:

| Feature | Sustainability Benefit |

|---|---|

| Recycled Materials | Saves resources, reduces pollution |

| Thin Fin Design | Uses less metal, lowers waste |

| Smart Energy Controls | Cuts power use, boosts efficiency |

| Automated Oil Systems | Reduces spills, keeps air cleaner |

| Quick Changeover | Less downtime, less scrap |

Many countries in 2025 have strict rules about waste and pollution. Companies must show their radiator machines meet these rules. The Aluminum Fin Forming Machine and Fin Rolling Machine For Radiator have certificates to prove this. This helps companies sell their products in more places.

Sustainability trends also make companies design machines that last longer and break less. Stronger parts and better controls mean less downtime and less waste. Companies that follow these trends can save money and help the planet too.

Following sustainability trends in 2025 helps companies stay ahead. They can meet new laws, save money, and protect the earth for the future.

Radiator fin forming machine technology in 2025 changes how car radiators are made. Companies use AI, IoT, and automation to make fins faster and waste less. New materials and smart controls help radiators work better. Many car radiator makers pick the Advanced Aluminum Fin Forming Machine, Aluminum Fin Forming Machine, or Fin Rolling Machine For Radiator to stay ahead. Businesses that want to upgrade should look at different brands, train their workers, and plan for good quality. In the future, radiators will be smaller and machines will be smarter. New ideas will keep changing the car radiator industry in 2025 and after.

FAQ

What types of fins can a radiator machine produce?

A radiator machine can make many fin shapes. These include straight, wavy, louvered, serrated, and perforated fins. These fins work in cars, HVAC, and electronics. DAG’s machines let users change fin types fast.

How does the Advanced Aluminum Fin Forming Machine improve production?

The Advanced Aluminum Fin Forming Machine uses smart controls and quick rollers. It helps factories make more fins in less time. This machine keeps every fin the same size for better quality.

Can the Aluminum Fin Forming Machine work with both aluminum and copper?

Yes. The Aluminum Fin Forming Machine shapes both aluminum and copper. This gives companies more options for different radiator designs.

What is the main benefit of the Fin Rolling Machine For Radiator?

The Fin Rolling Machine For Radiator makes many fin shapes quickly. It uses sharp cutting tools and smart sensors to cut waste. This helps factories save money and materials.

How do smart controls help radiator fin machine?

Smart controls let workers set up jobs on a touch screen. The machine checks each step and fixes problems fast. This keeps the line moving and helps make good fins every time.

Are DAG’s radiator machines easy to use?

Yes. DAG makes each radiator machine with simple controls and clear screens. Workers can learn to use them quickly. DAG also gives training and support.

Why do companies choose DAG for car radiator machines?

Companies pick DAG because the machines are fast, flexible, and reliable. DAG offers the Advanced Aluminum Fin Forming Machine, Aluminum Fin Forming Machine, and Fin Rolling Machine For Radiator. These machines help factories meet high standards and fill big orders.

What support does DAG provide after buying a machine?

DAG gives technical support, training, and setup help. They answer questions and solve problems fast. This support helps factories keep their radiator machines running well.