Radiator Plastic Tank Crimping Machine Factory

DAG plays a vital role in the development and manufacture of radiator plastic tank crimping machines. We provide professional solutions for manual, semi-automatic and fully automatic equipment. Welcome to inquire!

DaG-Radiator Plastic Tank Crimping Machine

The radiator plastic tank crimping machine is used to crimp the teeth of the header plates and lock the plastic tank tight to the core body to form a sealed space between the crimped plastic tank, sealing gasket, and header plate.

Our company supplies manual plastic tank crimping machines, semi-automatic pneumatic and servo-type plastic tank clinching machines, hydraulic and pneumatic-type plastic tank crimping machines, and fully automatic plastic tank clinching machines.

Customized options are also available, depending on your detailed requirements. Please contact us for more assistance.

Machine By Features

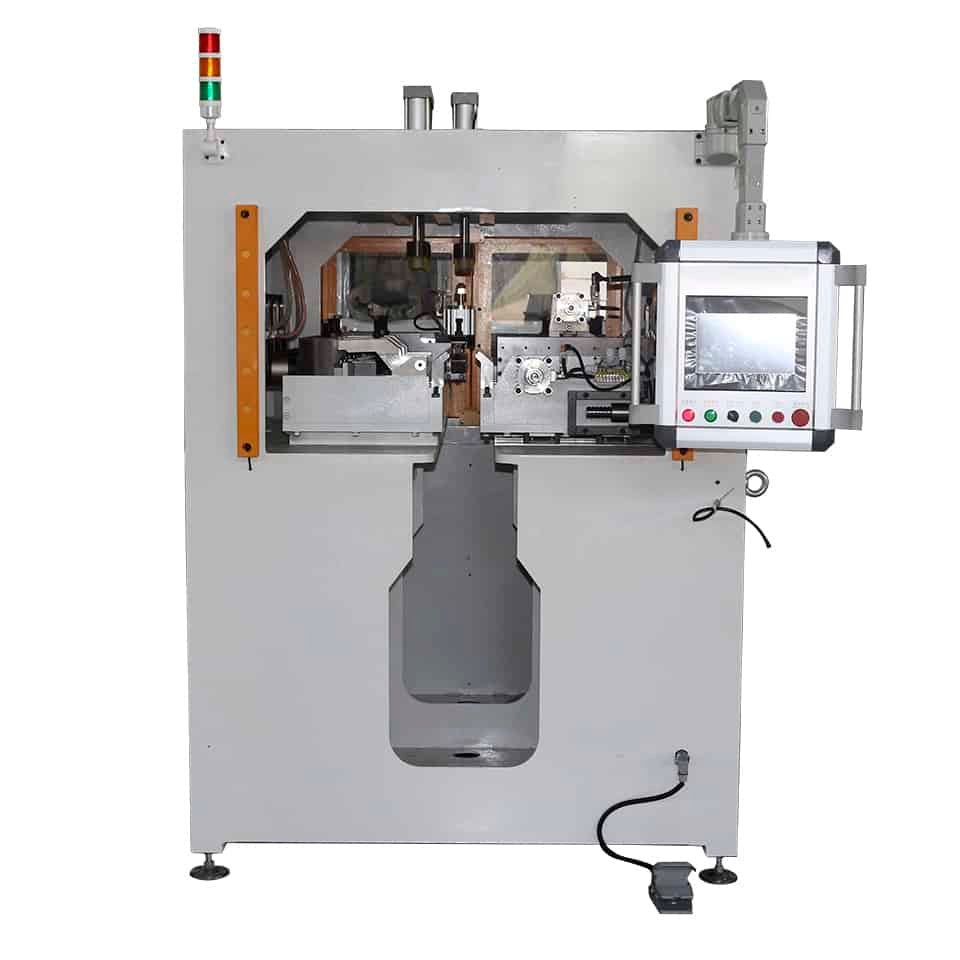

This radiator plastic water tank crimping machine is driven by a cylinder. It tightly combines the plastic water chamber with the radiator core to ensure that the coolant circulates in the radiator, which is the last process to complete the radiator manufacturing.

The radiator plastic tank crimping machine is used to crimp the teeth of the header plates and lock the plastic tank tight to the core body to form a sealed space between the crimped plastic tank, sealing gasket, and header plate.

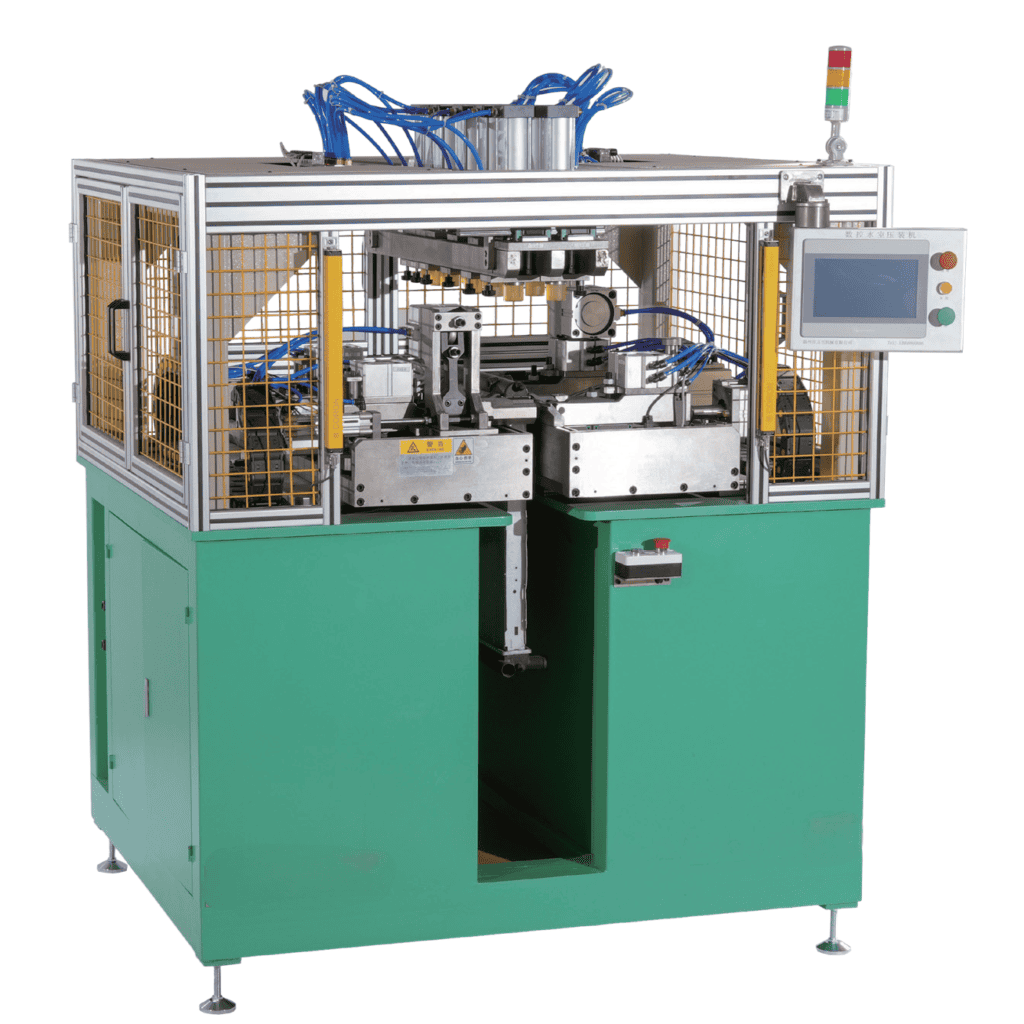

The driving force of this radiator plastic water tank is that the clinching machine is servo + pneumatic, which presses the teeth of the header plate and locks the plastic water tank on the core.

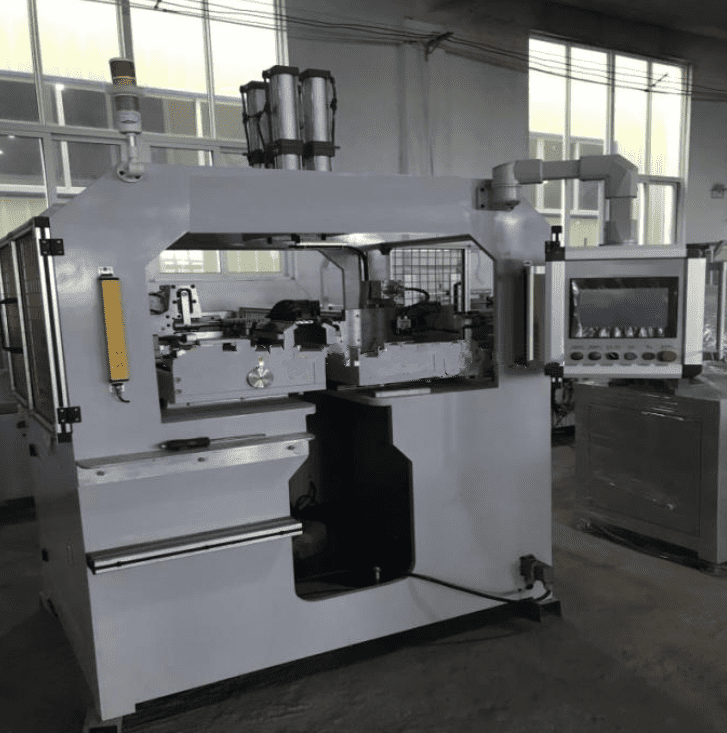

This automobile plastic water chamber crimping machine firmly clamps the header plate mold on the edge of the plastic water tank so that the core and the plastic water tank are tightly assembled. Suitable workpiece size: core height direction: 350-950mm, core width direction: 100-800mm.

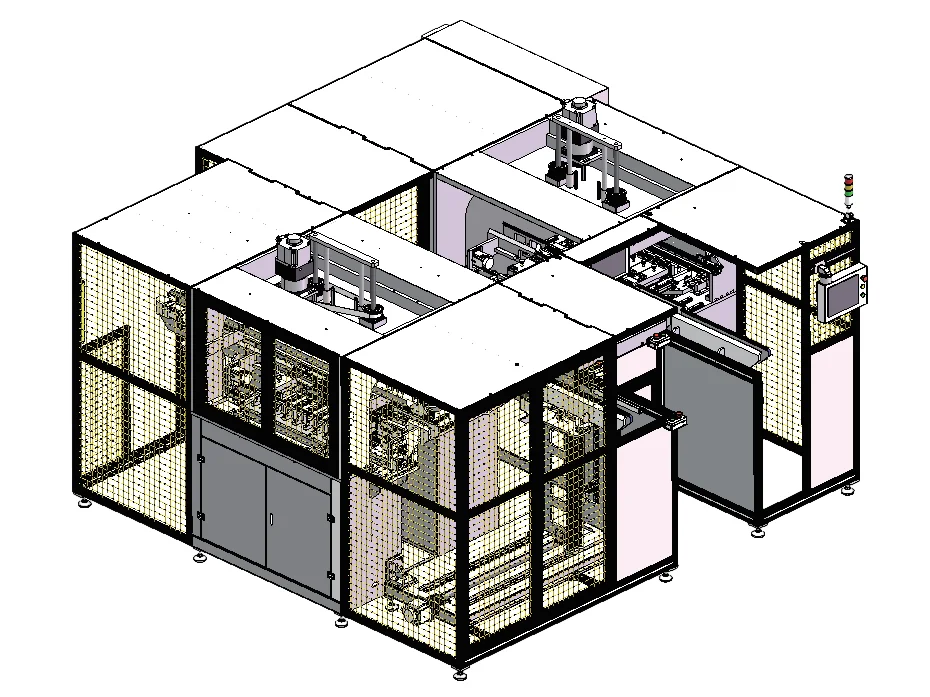

Water tank crimping machines are also called crimping machines, water tank crimping machines, radiator water tank crimping machines, plastic water tank crimping machines, etc. The fully automatic aluminum radiator plastic tank crimping machine only requires the operator to place the core, place the gasket and plastic water tank, and then load the core to the workstation. Then, just press the run button.

This manual plastic tank crimping machine is used to handle products of various specifications in repair workshops. The manual radiator plastic tank crimping machine can only crimp the long-side header plate. The two ends of the header plates should be crimped manually on a different machine.

The 110 mm maximum core height workpiece truck radiator plastic tank clinching machine is suitable for installing water chambers with a small number of single models. It is simple to operate, and workers only need a short period of training. One or two workers can operate at the same time.

The four-side radiator plastic tank crimping machine is PLC controlled. The control system stores radiator crimping parameters and the crimping program is set up on the touch screen. It can crimp the header on four sides in one cycle.

The radiator plastic tank crimping machine drives the left and right crimping device forward through the ball screw driven by the servo motor. The equipment has functions such as plastic tank water inlet dodge and virtual travel speed-up, making itself suitable for crimping plastic tanks and header plates of different specifications.

The equipment is easy to operate. The two workstations placed in the water chamber are relatively close to each other, with a short movement distance. It can be operated by a single person, offering high efficiency and affordable prices. Welcome to inquire!

The radiator plastic water tank crimping machine is driven by a cylinder to tightly connect the plastic water chamber with the radiator core to ensure that the coolant circulates in the radiator. DAG radiator plastic water tank crimping machine is economical and affordable. Welcome to inquire! Welcome to buy!

This high-quality four-sided plastic radiator water tank crimping machine is used to crimp the teeth of the header plate and firmly lock the plastic water tank on the core. This servo-type plastic water tank crimping machine can handle products of various specifications. Welcome to inquire!

Advantages of Radiator Plastic Tank Crimping Machine

Simple Operation

Operators only need one day of training using a PLC control system to operate, and one or two workers can operate simultaneously.

Stable Performance

The finished product qualification rate is high, customer satisfaction is high, and the repurchase rate reaches 90%+.

Various Models

Applicable to products of different specifications and different operating methods (manual, semi-automatic, fully automatic)

Fast shipping

With more than ten years of manufacturing experience built by a professional team, the supply capacity is 30 units/set, and the delivery time is 40 days.

How to Choose Radiator Plastic Tank Crimping Machine

DAG offers various types of radiator plastic water tank crimping machines. You can choose from manual, semi-automatic, and automatic models. Let’s take a closer look at a few of them.

Manual: Suitable for products of various specifications, with low production capacity and low efficiency.

Semi-automatic: Low price, simple operation, suitable for multi-model and small batch production situations

Automatic: More than 200 models can be set for positioning press production. It has high production efficiency and fast speed. It is suitable for the production mode of a single model and batch production quantity.

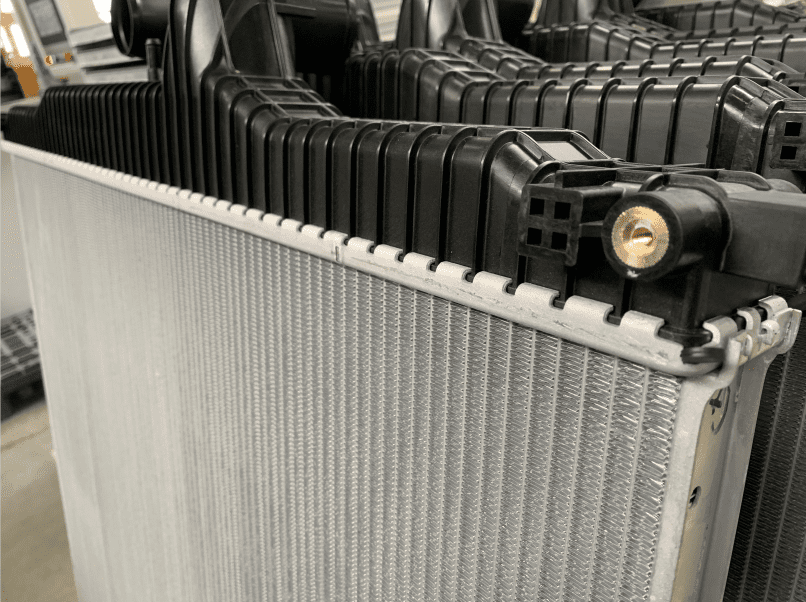

Finished Product Display Results

People Also Ask

Q: How many types of radiator plastic tank crimping machines are there?

A: Our company supplies manual plastic tank crimping machines, semi-automatic pneumatic and servo-type plastic tank clinching machines, hydraulic and pneumatic-type plastic tank crimping machines, and fully automatic plastic tank clinching machines. We can customize the machines according to your needs.

Q: Which one is better, an automatic crimping machine or a semi-automatic crimping machine?

A: An automatic crimping machine is suitable for a single model order of 300 sets or more at a time. It is ideal for this production plan, as it has more models but less quantity.

Q: How many model types can an automatic radiator plastic tank crimping machine system store?

A: Because it is a PLC interface setting, it can store about 200 different tank models and positions and covers most car models.

Q: What is the maximum size of the radiator produced by your plastic tank crimping machine?

A: The maximum workpiece size we produce is L1000*W900mm, and we can customize the machine according to your size.