Radiator Core Assembling Machines That Set the Standard in Automotive Manufacturing

DAG and other top brands are the best in radiator core assembling machines for 2025. Picking the right machines helps car makers work faster and make better products. The most important things are automation, new technology, customization, and value.

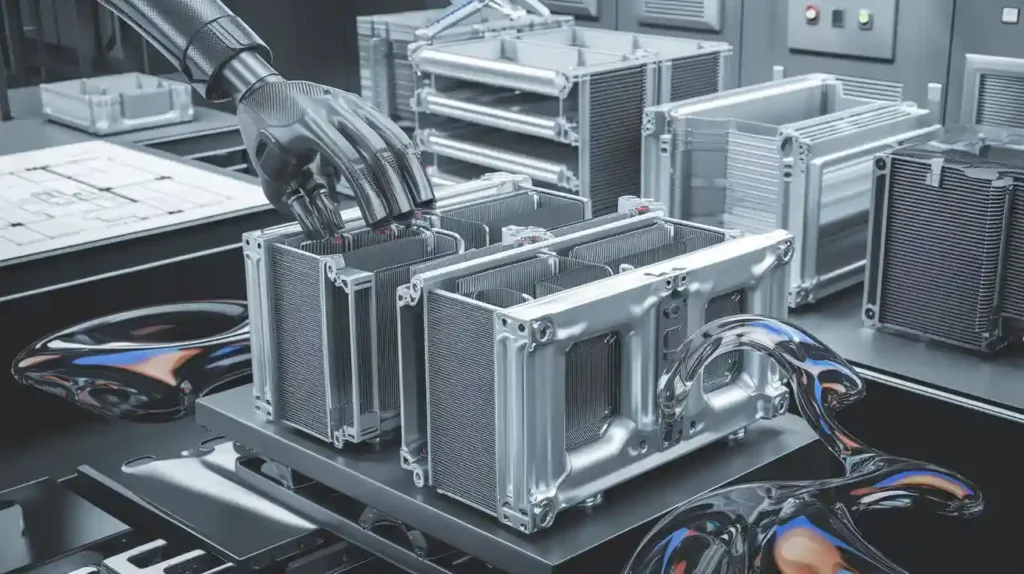

Core builder machine for aluminum radiator & condenser

A core builder machine puts together aluminum radiator and condenser cores. It does this by placing tubes, fins, header plates, and side plates together. DAG makes machines that line up tubes and fins very well. This helps the radiator work better and makes the product higher quality. Companies use these machines to build faster and get the same results each time. Automation and computer controls help the machines work quicker and need less workers. The machines work well and have checks to make sure things are done right. This helps companies make more products and save money.

Radiator core builder machine cost you can trust

Radiator core builder machine cost is usually $36,000 to $37,000 per set. Many things can change this price. Automation level, customization choices, and brand reputation all matter. DAG sells machines that work well and last long. Buyers should think about the first cost and the long-term value these machines give.

How to Choose the Right Radiator Core Builder Machine for Your Factory

Choosing the right radiator core builder machine means checking what your factory needs. You should look at machine features, automation, compatibility, cost, and support. Each factory must pick a machine that matches its radiator production goals. The best machine will fit the factory size, the types of radiator products, and how much automation is needed. DAG gives machines that help factories make radiator cores very accurately. Factory managers should pick machines that work for both current and future radiator lines.

How Radiator Making Machines Shape Automotive Cooling

Radiator making machines are important for keeping car engines cool. These machines help make strong radiators that last a long time. New machine designs have changed how factories build radiators. Modern machines use advanced brazing, like vacuum brazing. This makes joints stronger and stops rust. Factories now use flat tubes with micro-channel and louvered fins. These parts help move heat better. Some machines, like the radiator core builder machine, put parts together very carefully. Today, radiator making machines help make radiators that work well, last long, and fit many cars.

Radiator Core Builder Machine Matchup Manual, Semi-Auto, or Auto

Choosing the right radiator core builder machine affects how things are put together. Small workshops usually pick a manual machine for radiator assembly and making fewer products. Medium companies like semiautomatic machines because they give control and work faster for radiator assembly. Big factories use automatic machines, which lead the world market for radiator assembly with fast and steady results. Picking the right machine for your work, money, and skills makes assembly faster and saves money. DAG has radiator core builder machine choices for every need, helping companies do better at radiator builder machine assembly.

The Ultimate Guide to Core Assembly Machine Uses in Automotive and Beyond

A core assembly machine makes important parts in factories. It helps put products together quickly and correctly. In the automotive industry, automation is growing fast in North America and Asia-Pacific. Flexible assembly lines and robots help make more cars and electric cars.

Top 10 Trusted Radiator Machine Suppliers for Your Business

Business owners who need good radiator machine suppliers know that every minute lost can cost money. A trusted radiator manufacturer helps stop problems and keeps work going. People in the industry see that strong parts from good manufacturers help stop expensive stops. Automotive radiator manufacturers and others need suppliers who give high-quality radiator machines. The right supplier can give a Radiator Making Machine that fits your vehicle needs. Picking from a chosen radiator manufacturers list helps businesses find the best radiator brands and answers for their work.

The Ultimate Guide to Choosing the Right Core Builder Machine for Your Automobile Radiator

The core builder machine is crucial in ensuring the efficiency and longevity of automobile radiators. It is responsible for assembling the radiator’s core, which consists of the tubes and fins that facilitate heat transfer. Choosing the suitable core builder machine is essential for any automotive radiator manufacturer, as it directly impacts the quality and performance of the final product.

Advantages of Radiator Core Builder Machine

If you’re running a manufacturing business that deals with radiators, you know how important it is to have a reliable and efficient radiator core builder machine. This machine is a game-changer for improving your manufacturing process and increasing productivity. Not only does it save you time and money, but it also provides consistent quality that meets industry standards. This article will explore the benefits of using a radiator core builder machine for your business. From increased efficiency to reduced labor costs, we’ll show you why investing in this machine is a wise decision that can take your business to the next level. So, whether you’re a seasoned manufacturer or starting, read on to discover the advantages of using a radiator core builder machine and how it can benefit your business.