DAG and other top brands are the best in radiator core assembling machines for 2025. Picking the right machines helps car makers work faster and make better products. The most important things are automation, new technology, customization, and value.

- Advanced machines use robotics, AI, and smart controls. These features help stop delays and make more products.

- Modular designs and material compatibility help companies change for new cars and rules.

- Flexible assembly works for small shops and big factories. It gives steady results and can be changed for different needs.

Key Takeaways

- The best radiator core assembling machines use automation. Smart controls help make more radiators faster. These features also help stop mistakes from happening.

- Companies can change machines to fit different radiator sizes. They can also adjust for different materials and designs.

- Some machines work with aluminum, copper, and brass. This lets companies make many types of radiators.

- Fully automatic machines lower labor costs. They also make products more alike. Semi-automatic machines are better for small shops.

- Digital monitoring and smart PLC systems find mistakes early. They help keep production running smoothly.

- Picking machines with the right size and automation helps businesses reach their goals. It also makes work more efficient.

- Getting materials locally and changing with price trends is important. These are big changes for radiator manufacturing in 2025.

- Good support and easy-to-use machines help companies start fast. They also help keep products high quality.

Top Radiator Core Assembling Machines

Industry Leaders

Many car groups say some brands are the best for radiator core assembling machines in 2025. These companies spend money on new ideas and work with car makers. They make better machines by using automation and brazing technology. Their machines can handle alloy processing, core assembly, and thermal testing. They grow bigger by joining with other companies. They also help car makers build special cooling systems.

| Recognized Industry Leader Brands in 2025 |

|---|

| COMCO EUROPE |

| HANATECH |

| MMI-UK |

| Innovative Automation |

| Voss Manufacturing |

| DST |

| Schöler |

| LOGICS CORPORATION |

| JDM Jingda Machine |

| 3V |

| Forrich |

| DETZO |

| Hong Shing Machinery Enterprise |

| Chang I In Co., Ltd. |

| Tianjin Lonnie Technology Development |

| DaG MC |

Some makers like Shanghai YUYIN Radiator Machinery Co., Ltd., Shandong Hiteper Radiator Machinery Co., Ltd., and Guangzhou Sivan Machinery Co., Ltd. are also important. These companies build machines for big jobs and help with advanced automation.

Flagship Models

Radiator core assembling machines help car makers work fast and make parts that fit well. The DAG Radiator Core Builder Machine is the top choice for 2025. This machine puts together header plates, side plates, fins, and flat tubes to make a strong core. DAG has different models like 2-row, 4-row, and 5-row. They also have PLC-controlled and servo pneumatic types. These machines run smoothly, are easy to use, and do not make much noise. They place flat tubes in the right spot and spread fins evenly.

The ZPX-280 model is also very good. It uses smart automation and can change for different jobs. It can work by itself and needs less help from people. Makers pick these machines because they can handle many tube shapes and sizes. This helps them keep up with new needs.

Machines from top brands use smart controls, PLCs, and servo systems. They can be changed for OEM and ODM needs. These machines give steady results and work for both small shops and big factories.

Tip: Companies that buy machines with lots of automation and ways to change them can make products faster and better.

Features of Automotive Radiator Core Making Machine

Automation

Automotive radiator core making machines use automation to work faster and better. These machines put radiators together with less hand work and fewer mistakes. Automated decoiler units feed steel using hydraulic mandrel expansion and ultrasonic loop control. Automated spot welding lines up and holds radiator panels before multi-spot welding. Multi-spot welding uses many guns to make strong, even welds. Seam welding with copper wheels and inside cooling stops oxidation. TIG welding makes strong welds with little bending. Automated panel trimming systems cut edges straight. Robotic panel stacking puts panels in order, so people do not have to move them as much. Fixture assemblies carry panels to robotic welding stations and keep them lined up. Using robotic stacking and automated welding helps work go faster and stay the same each time.

Smart Controls

Smart PLC control systems run different radiator types and settings. Servo motors change movements right away to make things more exact. Machines like the DAG Radiator Core Builder Machine can be fully automatic. These machines need less hand work and make fewer mistakes. Safety sensors and error correction systems keep workers safe and stop long breaks. Digital factory integration lets people watch and control machines from far away.

Tube Dispensers

Tube dispensers in these machines put flat tubes in the right place. These dispensers make sure fins are spread out evenly and tubes are set just right. Automated tube laying works for many tube shapes and sizes. This helps makers build brazed copper-brass radiators that are always good quality.

Technology

PLC and Servo Systems

PLC and servo systems make the machines easier to use and faster. These systems make less noise and help keep people safe. Servo motor driving with PLC control keeps things very exact. Operators think these machines are simple to use. Good performance means radiators are put together the right way. DAG’s machines can work with many core sizes and types, so they do more jobs.

Digital Monitoring

Digital monitoring watches every step in the assembly process. It finds mistakes right away and lets workers change jobs quickly. Automated matrix machines and core fin radiator machines can make special fin shapes. Automated quality checks make sure every radiator is up to standard. Digital factory systems let people control and watch machines from far away.

Customization

OEM/ODM Options

Makers pick customization options to fit their needs. OEM and ODM services let machines match special sizes, fin heights, and rows. Machines can be manual, semi-automatic, or fully automatic. Hydraulic and pneumatic parts, safety tools, and programmable controls help with different jobs.

Material Adaptability

Automotive radiator core making machines work with many materials. These machines build radiators, condensers, and heater aluminum cores. Material compatibility lets makers build brazed copper-brass radiators and other kinds. Machines can change for different tube types and fin heights. The biggest core size can be up to 1200*1200mm with two rows. Customization helps makers build brazed copper-brass radiators for many uses.

| Model Type | Precision Level | Efficiency Level | Customization Scope |

|---|---|---|---|

| Base Model | Standard | Base | Limited |

| Advanced Model | 15% higher than base | Enhanced | Moderate |

| Pro Model | 30% higher than base | Premium | Extensive |

Automotive radiator core making machines use new technology to save energy and help the industry grow. Makers trust these machines to build brazed copper-brass radiators that are high quality and work with many materials.

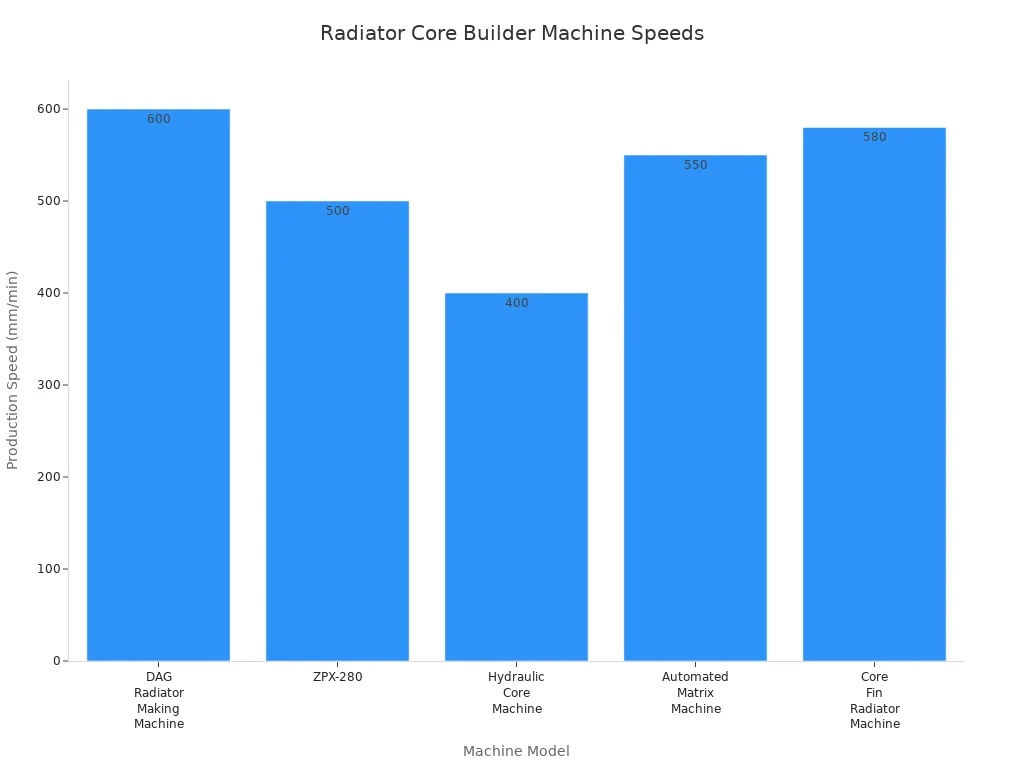

Radiator Core Assembling Machines Comparison

Specifications

Radiator core assembling machines help factories build radiators quickly and accurately. Each machine model has different automation, speed, and material options. The table below shows the main features of top machines:

| Machine Model | Automation Level | Production Speed (mm/min) | Supported Core Sizes (mm) | Material Compatibility | Customization Options |

|---|---|---|---|---|---|

| DAG Radiator Making Machine | Full | Up to 600 | 150 – 800 | Aluminum, Copper | Yes |

| ZPX-280 | Semi/Full | Up to 500 | 120 – 700 | Aluminum | Yes |

| Hydraulic Core Machine | Semi | Up to 400 | 100 – 600 | Aluminum, Brass | Limited |

| Automated Matrix Machine | Full | Up to 550 | 130 – 750 | Aluminum | Yes |

| Core Fin Radiator Machine | Full | Up to 580 | 140 – 780 | Aluminum, Copper | Yes |

The DAG Radiator Making Machine is special because it is fully automatic and very fast. It can make many core sizes and works with aluminum and copper. ZPX-280 can be semi or fully automatic and fits many core sizes too. Other machines work with different materials, like brass, and let you change some settings.

Unique Features

Top radiator core assembling machines give factories big benefits in car making. These machines have many helpful features:

- Integrated production platforms let factories do alloy processing, core assembly, and thermal testing in one place. This helps control quality and save money.

- Working with material suppliers and OEMs lets companies use new brazing and composite technology.

- Spending on research and development helps with fast prototyping, digital twins, and new ways to check designs.

- Smart automation keeps the process steady and makes less waste. Predictive maintenance helps machines last longer.

- In-house tooling lets factories change setups fast and make custom parts. This helps them build many types of radiators, like brazed copper-brass radiators.

- These features help companies make good radiators for many cars and trucks.

Note: Factories using smart automation and in-house changes can make radiators faster and try new designs easily.

Market Trends

Manufacturers have new problems in 2025. Tariffs on imported aluminum and copper-brass parts make things cost more. Many companies now buy from local suppliers and use nearby supply chains. They also move steps like extrusion and brazing closer to their factories. This helps lower tariff risks and keeps work going.

Material prices keep going up. Aluminum cores are popular because they are light and move heat well. Copper-brass cores are still used because they are strong and easy to fix, but they cost more. Some factories use plastic composite cores to save money and make radiators tougher against chemicals and bumps.

To handle these changes, companies use automation and lean methods. They work with suppliers to plan costs and invest in local factories. These actions help keep radiators cheap and good quality. Factories now use just-in-time inventory but also keep extra stock to handle tariff changes. They ship in big groups from close factories to save money.

Tip: Knowing about tariffs and material changes helps companies pick the best radiator core assembling machines and stay ahead.

Model Reviews

DAG Radiator Core Builder Machine

DAG is well known for its Radiator Core Builder Machine. This machine puts together header plates, side plates, fins, and flat tubes. It uses PLC and servo systems to work better and faster. Operators say it places flat tubes in the right spot. It also spreads fins evenly every time. DAG has models with 2, 4, or 5 rows. The machine can change for different jobs and lets you pick OEM or ODM options. People like that it is quiet and simple to use. Many factories use it to make brazed copper-brass radiators for cars and trucks. DAG gives help and advice at the factory, so companies can start making radiators quickly.

Note: DAG’s machine works with many core sizes and materials. This makes it good for lots of radiator types.

ZPX-280

The ZPX-280 model builds radiators in a steady way. It uses smart automation and digital monitoring to help workers. You can pick semi-automatic or fully automatic modes. Operators think the controls are easy and the machine is simple to fix. ZPX-280 works with many tube shapes and sizes. It makes radiators that are always good quality. Many people choose this model because it can handle big or small jobs. It also makes brazed copper-brass radiators for cars and trucks. Users say the machine works well and can change for different needs.

- Key Features:

- Automated tube dispensers

- Digital monitoring for quality control

- Adjustable settings for core sizes

Other Notable Models

Other machines also help make radiators in factories. Hydraulic core machines have basic automation and use aluminum and brass. Automated matrix machines do all the work by themselves and handle hard jobs. Core fin radiator machines shape and stack fins for radiators. These machines help build radiators for many kinds of vehicles. Some machines are made for heavy-duty brazed copper-brass radiators. Operators like switching between tube types and fin heights. Factories use these machines to keep up with new market needs and work faster.

| Model Name | Automation Level | Main Use Case |

|---|---|---|

| Hydraulic Core Machine | Semi | Small batch radiators |

| Automated Matrix Machine | Full | High-volume production |

| Core Fin Radiator Machine | Full | Fin shaping and stacking |

Tip: Picking the right radiator core making machine helps companies work fast and keep good quality for all their products.

Selection Criteria

Capacity

Production capacity is very important when picking radiator core assembling machines. Companies need machines that fit their daily goals. Some machines make radiators fast. Others focus on making small batches with care. For example, the Sunhope Radiator Core Builder Machine makes one radiator core in 4 to 5 minutes. It can build cores up to 800x800x100 mm. Sedin Engineering’s semi-automated machine makes one core every 2 minutes. It can handle five different radiator core sizes. These examples show how much production capacity can change.

| Machine Name | Production Capacity (Assembly Time) | Core Height Range (mm) | Core Thickness Range (mm) |

|---|---|---|---|

| Semi-automatic Core Builder | 60-120 seconds per set | 300 – 850 | 16 – 56 |

Companies should think about how many radiators they want to make each day. Big factories need machines that work faster. Small shops may pick machines that can change settings for different sizes. Picking the right production capacity helps companies work well and fill orders.

Tip: Getting a machine with the right speed helps companies avoid waiting and finish orders on time.

Automation Level

Automation level changes how radiators are put together and how much hand work is needed. Machines can be manual, semi-automatic, or fully automatic. Fully automatic machines use computers and sensors to line up parts and check quality. Semi-automatic machines mix hand work with some automatic steps. Manual machines need more help from workers and are good for small jobs.

DAG’s core builder machine uses PLC and servo systems to put parts together exactly. Workers can pick automatic or manual mode for each job. Automated machines make fewer mistakes and keep results steady. They also help save money by needing less work and making less waste. Factories with more automation work faster and better.

Note: The automation level should fit the workers’ skills and how hard the radiator is to make.

Material Compatibility

Material compatibility shows what kinds of radiators a machine can build. Most car radiators use aluminum because it is light and cools well. Copper and brass are used for strong, heavy-duty radiators. Machines that work with both aluminum and copper give more choices.

| Machine Model | Material Compatibility |

|---|---|

| DAG Radiator Making Machine | Aluminum, Copper |

| Hydraulic Core Machine | Aluminum, Brass |

| Core Fin Radiator Machine | Aluminum, Copper |

Core builder machines put together header plates, side plates, fins, and flat tubes. DAG’s machine is special because it can switch quickly between different shapes and materials. This helps companies make many types of radiators for different cars. Picking a machine that works with many materials helps companies keep up with new trends and customer needs.

Tip: Machines that work with more materials help companies make more products and follow new car trends.

Customization

Many factories need radiator core assembling machines that fit their own needs. Customization lets companies pick machines for special core sizes, fin heights, and tube types. Suppliers like DAG give OEM and ODM services. These services help companies get machines that work for their products.

A company might make radiators for many vehicles. Customization lets them change the machine for each job. Some machines switch fast between core sizes or materials. This helps factories handle new orders or market changes.

Key customization choices are:

- Settings to change core size

- Fin height and tube spacing can be changed

- Modular parts for easy upgrades

- Software for different jobs

A table shows how features help:

| Feature | Benefit |

|---|---|

| Adjustable core size | Works for many radiator types |

| Modular design | Easy to fix or upgrade |

| OEM/ODM services | Fits special needs |

| Programmable controls | Quick setup for new jobs |

Tip: Customization lets companies stay ready for new jobs and meet customer needs without buying new machines.

Cost

Cost is very important when picking a radiator core assembling machine. Companies look at the price, but also think about long-term costs. These include fixing the machine, energy use, and needing skilled workers. A machine with more automation may cost more at first, but it can save money later by using less labor and making fewer mistakes.

Manufacturers compare the total cost to own the machine. This means the first price, setup, training, and support. Some machines save money by using less energy or needing fewer repairs. Companies also check if the machine can use local materials, which saves on shipping and import fees.

When thinking about cost, companies should ask:

- What is the first price?

- How much will fixing and upkeep cost each year?

- Does the machine save on labor or materials?

- Can it change for future needs without big upgrades?

Careful cost checks help companies pick machines that fit their budget and help them grow.

Note: Picking the right machine helps a business control costs and make more money over time.

Recommendations for Automotive Manufacturing

High-Volume Solutions

Car factories that make lots of radiators need fast and accurate machines. The Servo Type Intercooler Core Assembly Machine is great for this job. It uses hydraulic, pneumatic, or servo power to put radiator cores together. The machine can place parts with an accuracy of ±1.5 mm. Each core takes about 60 seconds to build. It can make up to 100 sets every year. The machine works with header-to-header sizes from 300 to 1000 mm. It fits fin widths from 16 to 32 mm. It can hold up to 80 flat tubes with 10 mm between each. Workers say the machine is steady and easy to use. It does not make much noise and puts fins in the right place. The table below shows its main features:

| Feature | Details/Specification |

|---|---|

| Machine Type | Servo Type Intercooler Core Assembly Machine |

| Driving Force | Hydraulic, Pneumatic, or Servo |

| Application | Assembling auto radiator cores |

| Assembling Accuracy | ±1.5 mm |

| Assembling Time per Core | About 60 seconds |

| Production Capacity | Up to 100 sets per year |

| Core Dimensions | Header-to-header: 300-1000 mm |

| Fin Width | 16, 18, 20, 24, 26, 32 mm |

| Flat Tube Quantity | Max 80 pcs (spacing 10 mm) |

| Power | 3 kW (machine), total 5.5 kW |

| Weight | 2500 kg |

| Operation Features | Stable, reliable, easy operation, low noise, accurate positioning, even fin distribution |

| Suitability | High-volume automotive radiator core assembly |

Using this machine helps factories save energy and get the same results every time. It is good for making lots of radiators in busy car factories.

Advanced Technology

Car makers who want new features pick machines with smart technology. These machines can work with many radiator core sizes and tube types. They use special tools like core builders, fin forming machines, plastic tank crimping machines, and aluminum brazing furnaces. All these tools help finish the whole radiator assembly.

- Machines use aluminum brazing furnaces to join radiator parts well.

- OEM and ODM services let companies change machines for their needs.

- Prototyping and CAD/CAM software help design and change parts fast.

- Certifications like IATF 16949 and ISO 9001 show the machines meet car industry rules.

- Material traceability keeps quality high and makes sure parts are right.

- Customization, high precision, and fast work help meet hard jobs and push new ideas.

Buying these machines helps car makers build better radiators and work faster. They also follow strict rules and can change quickly when the market changes.

Best Value

Small and medium car shops need machines that are not too expensive but still work well. These machines are easy to use and do not need much training. Semi-automatic and manual machines help small shops save money and stay flexible. PLC memory lets workers save over 200 radiator tank models. This makes it easy to switch jobs and adapt. Servo and pneumatic drives help put parts together the right way and make better radiators.

Machines with modular and semi-automatic features mix automation and low cost. Good support, ways to customize, and quick shipping help small shops. DAG gives advanced automation and flexibility, but small shops often do better with semi-automatic or manual machines that fit their size and budget.

The Sunhope High Efficiency 8mm Fin Height 180m/Min Radiator Core Builder is a semi-automatic machine for smaller shops. One or two people can run the whole line. A skilled worker can build a radiator core in 3-5 minutes. The machine works fast and is simple to use. It is a good choice for small and medium car shops that want both automation and savings.

Tip: Small and medium car shops should pick machines that fit their size and money plan. This helps them keep quality high and costs low while building radiators well.

Customization

Car makers need radiator core assembling machines that fit their special needs. Customization is important for companies making radiators for many kinds of vehicles. These vehicles include cars, trucks, and special machines. Makers want machines that can change for different core sizes and fin heights. They also want machines that work with many tube shapes.

Many top companies give custom solutions. Bell Intercoolers makes many custom heat exchangers. Their team builds intercoolers, oil coolers, and core parts for high-performance jobs. They use new ways to make things and offer repair and fast delivery. This helps companies fill urgent orders and special needs.

Active Radiator helps customers with custom radiators and quick service. Their process gives high-quality cooling parts made for each job in about two weeks. This fast work helps car makers handle market changes and rush orders.

Griffin Manufacturing uses skilled engineers and smart software to design custom radiators. They use CAD and 3D modeling to plan and build each part. Their special brazing methods work for small batches or big orders. This lets companies get the exact radiator they need.

Makers also build radiators in custom sizes and shapes for different vehicles. These special radiators cool well and are easy to install. Companies can solve cooling problems for cars, trucks, and special machines by picking machines that allow customization.

3D printing is changing how radiators are made. This method lets makers build complex and custom designs. Radiators can have special inside shapes that help move heat better. Makers can also match the cooling system to each vehicle’s needs.

When picking a radiator core assembling machine, companies should look for these features:

- Settings that change core size, fin height, and tube space

- Modular parts for quick swaps

- Software that saves many job recipes

- Works with new materials and modern ways to build

Companies that buy machines with customization can serve many markets and change fast when trends shift.

Customization helps car makers meet tough rules and customer needs. By picking machines with good customization, companies get ready for success as the industry changes.

Top radiator core assembling machines in 2025 give big benefits to car makers. They use strong materials like aluminum and copper-brass. These materials help the machines last longer and move heat better. Digital tools and automation help the machines work faster and make better parts. Factories can use these machines to save money and change when the market does.

Manufacturers should think about how much automation they need and what their workers can do. They should use digital tools to watch and control the work. It is important to pick machines that fit the materials and how many parts they want to make.

Making smart choices helps factories work better, build good products, and save money for a long time.

FAQ

What does a radiator core assembling machine do?

A radiator core assembling machine puts together parts for radiators. It joins header plates, side plates, fins, and tubes. The machine makes the main part of a radiator for cars and trucks.

Which materials can these machines handle?

These machines work with aluminum, copper, and brass. Some models also use plastic composite cores for special cooling jobs.

How does automation improve radiator assembly?

Automation helps the machine work faster and makes fewer mistakes. It lines up parts, checks quality, and needs less hand work.

Can companies customize these machines?

Manufacturers give OEM and ODM services. Companies can pick core sizes, fin heights, and tube types for their needs.

What is the typical production speed?

Production speed depends on the model. Some machines build one radiator core in 60 seconds. Others take up to five minutes for each core.

Are these machines suitable for small businesses?

Small shops can use semi-automatic or manual machines. These models cost less and are easier to learn.

What support do manufacturers provide?

Manufacturers give technical support, training, and help with setup. Some offer on-site help to keep production running well.

How do companies choose the right machine?

Companies look at how many radiators they want to make. They check automation, material options, ways to customize, and cost. They pick machines that fit their business plans.