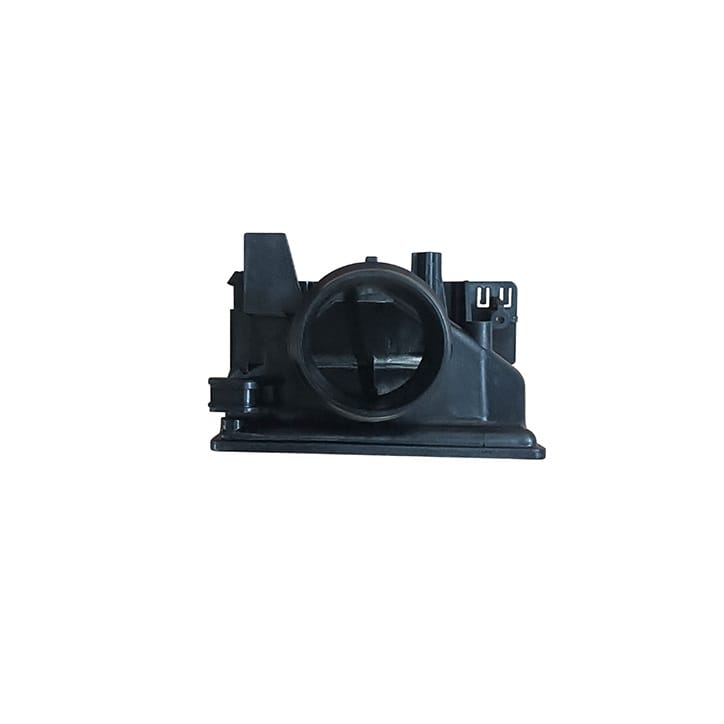

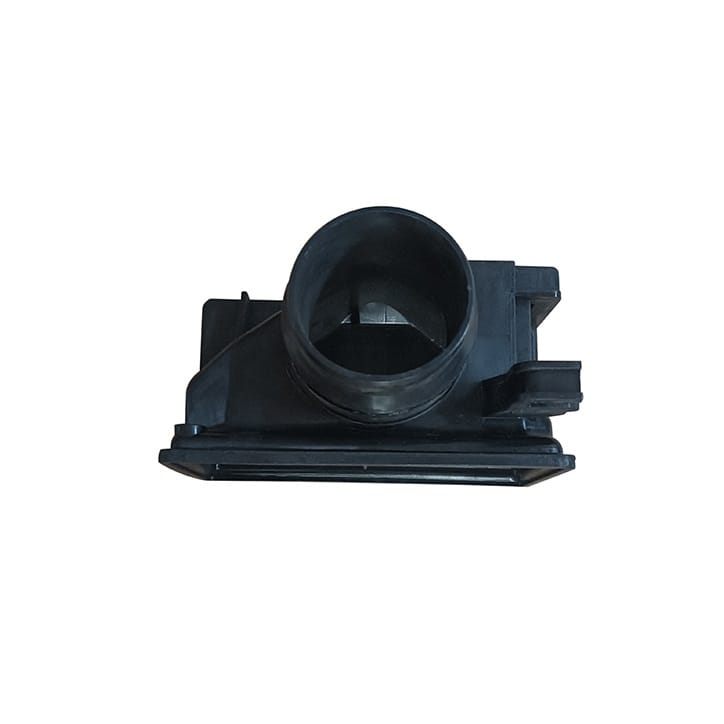

Product Overview

VOLVO XC40 19- Radiator Plastic Tank

Professional-grade OEM replacement radiator plastic tank engineered exclusively for 2019 and newer Volvo XC40 cooling systems. This critical component (OEM 31439780) is precision-molded from advanced thermoplastic composites to restore original equipment performance and durability.

Engineered Performance Features

VOLVO XC40 19- Radiator Plastic Tank

1. Dimensional Accuracy: Manufactured using OE CAD data for exact alignment with radiator core assemblies, mounting provisions, and fluid connection points—ensuring direct-fit replacement without modification.

2. Advanced Material Technology: PA66+GF30 polyamide reinforced with 30% glass fiber provides exceptional mechanical strength, thermal stability (-40°C to +135°C continuous range), and chemical resistance to prolonged coolant exposure.

3. Pressure Integrity: Integral O-ring sealing grooves maintain system pressurization up to 1.5 bar, preventing cavitation and ensuring optimal heat transfer efficiency across all engine operating conditions.

4. Weight & Corrosion Advantages: Polymer construction eliminates electrochemical corrosion while reducing mass by ~40% versus metallic equivalents, supporting vehicle efficiency targets.

Technical Specifications

VOLVO XC40 19- Radiator Plastic Tank

1. Material: PA66+GF30 (30% Glass-Filled Nylon 6,6)

2. Operating Temperature: -40°C to +135°C (Peak: +150°C)

3. Pressure Rating: 1.5 bar (21.7 psi) maximum working pressure

4. Connection Interface: Quick-disconnect couplers, 30 Nm torque spec

5. Manufacturing Process: Precision injection molding

Application Compatibility

VOLVO XC40 19- Radiator Plastic Tank

1. Primary Fitment: Volvo XC40 – 2019 Model Year

2. OEM Cross-Reference: 31439780, 32270946

3. Service Interval: Inspect every 60,000 miles; replace based on thermal fatigue or impact damage

VOLVO XC40 19 - RADIATOR PLASTIC TANK

This product is an original equipment manufacturer (OEM) replacement part, specifically designed for the radiator plastic water chamber (side tank) of the 2019 and later Volvo XC40 models. It is injection molded from high-temperature resistant engineering plastics and strictly adheres to Volvo’s original quality standards (OEM 31439780) to ensure a perfect match with the radiator core and cooling piping system. Wholesale Volvo XC40 radiator plastic tanks – manufacturer direct, cost-effective pricing, worldwide shipping. Premium OEM quality. Inquiries welcome. Long-term dealer partnerships available.

Product SKU: 9999

Product Brand: DAG

5