Product Overview

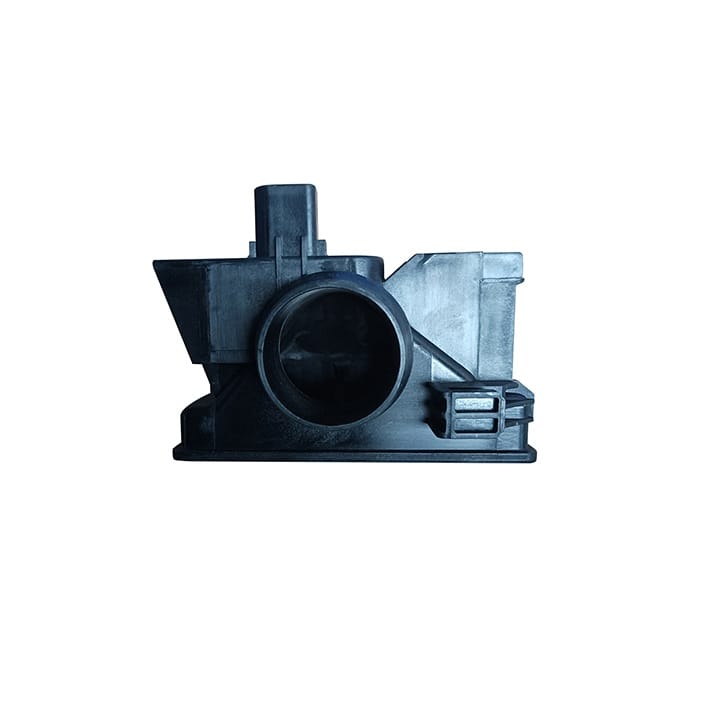

VOLVO S90 2.0T 18- RADIATOR PLASTIC TANK

Professional-grade OEM replacement radiator plastic tank (OEM Part No. 31410892) meticulously engineered for 2018 and newer Volvo S90 2.0T models . Precision-manufactured to restore factory cooling system performance and ensure thermal management reliability under all operating conditions.

Technical Specifications

1. OEM Part Number: 31410892

2. Application Range: Volvo S90 2.0T – 2018

3. Engine Compatibility: T5, T6, T8 Twin Engine (B4204T Series)

4. Material Construction: PA66+GF35 Glass-Filled Nylon

5. Temperature Rating: -40°C to +135°C (Peak: +150°C)

6. Maximum Working Pressure: 1.5 bar (21.7 psi)

7. Manufacturing Standard: IATF 16949 Certified Production

Professional Installation Requirements

VOLVO S90 2.0T 18- RADIATOR PLASTIC TANK

Certified technician installation mandatory per Volvo VIDA service procedures:

1. Systematically depressurize and evacuate cooling system; recover coolant per environmental regulations

2. Remove radiator assembly (recommended) or perform localized service; thoroughly clean sealing interfaces

3. Replace all associated O-rings, retaining clamps, and fasteners simultaneously; torque to Volvo specifications

4. Refill with Volvo-approved coolant (G48/G40 specification); execute system bleeding, pressure testing, and leak verification

5. Complete post-repair thermal cycle validation to confirm leak-free performance

VOLVO S90 2.0T 18- RADIATOR PLASTIC TANK

OEM-grade replacement radiator plastic tank engineered exclusively for 2018 and newer Volvo S90 2.0T models (SPA architecture). Precision-molded using advanced injection molding technology to restore factory cooling system integrity and thermal management performance. Wholesale Volvo S90 radiator plastic tanks – manufacturer direct, cost-effective pricing, worldwide shipping. Premium OEM quality. Inquiries welcome. Long-term dealer partnerships available.

Product SKU: 99999

Product Brand: DAG

5