Product Introduction

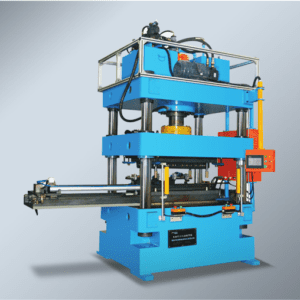

High-Precision Steel Frame Punch Press

Our high-precision steel punch press frames are welded from high-quality steel plates and stress-relieved for enhanced stability and reliability. The drive center is aligned with the center of the machine tool to ensure punching accuracy and stability.

Product Features

High-Precision Steel Frame Punch Press

1. In order to guarantee the machine runs stably and smoothly, adopt the design of symmetrical two slide boards with a balancer.

2. The precision of mould adjusting up to 0.1 mm, safety, reliability, and convenience.

3. Crank, gear, and connecting bar are oxidised hardening and milled, having a super comprehensive mechanical performance and durable function.

4. Using a reliable high-sensitive clutch brake and an international up double solenoid valve, an overload protector can guarantee the precision of slider running and stop the safe production of the machine.

5. Reasonable structural design is beneficial for automation production and reduces cost, improving efficiency.

6 . Advanced design principle, low noise, low consumption, low cost, and save energy.

Technical Parameters

High-Precision Steel Frame Punch Press

Table 1

| Name | unit | APA-25 | APA-35 | APA-45 | APA-60 | APA-80 | DAG-110 | ||||||

| Model | V型 | H型 | V型 | H型 | V型 | H型 | V型 | H型 | V型 | H型 | V型 | H型 | |

| Capacity | Ton | 25 | 35 | 45 | 60 | 80 | 110 | ||||||

| Rated tonnage point | mm | 3.2 | 1.6 | 3.2 | 1.6 | 3.2 | 1.6 | 4 | 2 | 4 | 2 | 6 | |

| Speed changing | s.p.m | 60-140 | 130-200 | 40-120 | 110-180 | 40-100 | 100-150 | 35-90 | 80-120 | 35-80 | 80-120 | 30-60 | 60-90 |

| Stable speed | s.p.m | 110 | 85 | 75 | 65 | 65 | 50 | ||||||

| Stroke | mm | 60 | 30 | 70 | 40 | 80 | 50 | 120 | 60 | 150 | 70 | 180 | |

| Die height | mm | 200 | 215 | 220 | 235 | 250 | 265 | 310 | 340 | 340 | 380 | 360 | |

| Slide adjustment | mm | 50 | 55 | 60 | 75 | 80 | 80 | ||||||

| Slide area | mm | 300*220*50 | 360*250*50 | 400*300*60 | 500*360*70 | 560*420*70 | 650*470*80 | ||||||

| Bolster area | mm | 680*300*70 | 800*400*70 | 850*440*80 | 900*500*80 | 1000*550*90 | 1150*600*110 | ||||||

| Shank hole | mm | Φ38.1 | Φ38.1 | Φ38.1 | Φ50 | Φ50 | Φ50 | ||||||

| Main motor | kw | 3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 11 | ||||||

| Air pressure | kg/cm² | 6 | 6 | 6 | 6 | 6 | 6 | ||||||

| Presses dimension (L*W*H) | mm | 1280*850*2200 | 1380*900*2400 | 1600*950*2500 | 1600*1000*2800 | 1800*1180*2800 | 1900*1300*3200 | ||||||

| Die cushion capacity | Ton | ﹣ | 2.3 | 3.6 | 3.6 | 3.6 | 6.3 | ||||||

| Stroke | mm | ﹣ | 50 | 70 | 70 | 70 | 80 | ||||||

| Die cushion effective area | mm² | ﹣ | 300*230 | 350*300 | 350*300 | 450*310 | 500*350 | ||||||

Table 2

| Name | unit | APA-125 | APA-160 | APA-200 | APA-260 | APA-315 | DAG-400 | ||||||

| Model | V型 | H型 | V型 | H型 | V型 | H型 | V型 | H型 | V型 | H型 | V型 | H型 | |

| Capacity | Ton | 125 | 160 | 200 | 260 | 315 | 400 | ||||||

| Rated tonnage point | mm | 6 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 8 | 4 | 8 | 4 |

| Speed changing | s.p.m | 30-60 | 60-90 | 20-50 | 40-70 | 20-50 | 40-70 | 20-40 | 40-50 | 20-40 | 30-50 | 20-40 | 30-50 |

| Stable speed | s.p.m | 50 | 35 | 35 | 30 | 30 | 30 | ||||||

| Stroke | mm | 180 | 80 | 200 | 90 | 200 | 100 | 250 | 150 | 250 | 150 | 250 | 150 |

| Die height | mm | 360 | 410 | 460 | 510 | 460 | 510 | 500 | 550 | 500 | 550 | 550 | 600 |

| Slide adjustment | mm | 80 | 100 | 100 | 120 | 120 | 130 | ||||||

| Slide area | mm | 650*470*80 | 700*550*90 | 850*630*90 | 950*700*100 | 1250*750*100 | 1350*800*100 | ||||||

| Bolster area | mm | 1150*600*110 | 1250*800*140 | 1400*820*160 | 1500*840*180 | 1600*860*190 | 1650*900*200 | ||||||

| Shank hole | mm | Φ50 | Φ65 | Φ65 | Φ65 | Φ65 | Φ65 | ||||||

| Main motor | kw | 11 | 15 | 18.5 | 22 | 30 | 37 | ||||||

| Air pressure | kg/cm² | 6 | 6 | 6 | 6 | 6 | 6 | ||||||

| Presses dimension(L*W*H) | mm | 1900*1300*3200 | 2300*1400*3800 | 2615*1690*4075 | 2780*1850*4470 | 2910*1950*4500 | 3180*2150*5025 | ||||||

| Die cushion capacity | Ton | 6.3 | 10 | 14 | 14 | 14 | 14 | ||||||

| Stroke | mm | 80 | 80 | 100 | 100 | 100 | 100 | ||||||

| Die cushion effective area | mm² | 500*350 | 650*420 | 710*480 | 810*480 | 710*480 | 710*480 | ||||||

Accessories

Standard Accessories

1. Hydraulic over-load protector

2. Manual operation slide Adjust device(TP below 60 )

3.Electrical driving Slide Adjust device(TP 60 or more )

4. Die height indicator (TP below 60)

5.Die height indicator(TP 60 or more)

6. Balance device

7. Air source receptacle

8. Against over-un safety device

9. Air ejector

10. Maintenance tool box

11. Operation manual

12. Inverter

13. Power supply

14. Auti-vibration press mount

15.7-Inch touch screen, electronic cam

16. Angle display

17. Tonnage measurement and protection devices

18. The bottom dead point detecting

Optional Accessories

1. High-performance wet clutch & brake

2 . Electrical automatic lubrication system

3 . Pneumatic die cushion device

4. Foot, switch

5 .Quick die change device(dielifter, clamp, and die amm sepias)

6. Slide knock-out device

7. Misfeed detection consent

8. Photoelectric safety device

9. Touch pad counter system

10. Automatic feeding device (Feeder, 7.UriCoHerLeveler)

11. Mechanism hand

12. Die room light

Our company can customize the stroke-adjustable punch press according to requirements.

Affordable Price Steel Frame Punch Press

Our punch presses utilize reliable, highly sensitive clutch brakes and internationally advanced dual solenoid valves. An overload protection device ensures precise slide movement and timely shutdown, ensuring safe production. Advanced design principles ensure low noise, low power consumption, low cost, and high energy efficiency. We can customize our equipment to meet your needs and budget at competitive prices. We welcome your inquiries and look forward to establishing long-term partnerships with you.

Product SKU: 20

Product Brand: DAG

5