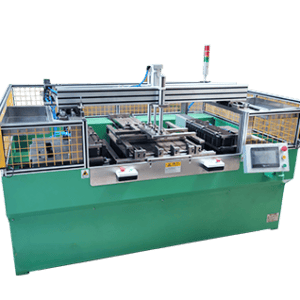

Machine Description

| Core Size | Can Customize | Thickness Of Fin | Usually 8mm Or 5mm |

| Number Of Working Station | 1 | Number Of Tubes | 3 Rows |

| Driving Mode | Pneumatics Or Servo Pneumatic | Working Principle | Semi-automatic Operation; Tube Dispenser |

| High Light | Three rows core builder machine,5mm fin radiator manufacturing equipment | ||

Servo Pneumatic Radiator Core Builder Machine Introductions:

- The radiator core builder can assemble the header plate, side plate, fins, and flat tubes as a core body.

- The core shall be further brazed in the CAB brazing furnace for brazing purposes.

- The core is well assembled, and the brazing quality can be assured.

- The mechanical movements of the radiator core builder are mutually interlinked to prevent wrong operation and possible damage.

- The current movement is unfinished, and the subsequent movement cannot be executed.

Machine Technical Parameters

Mold

Can customize

Shape

Unregular

Design style

Can customize

After-sale service

Yes

Driving mode

Servo and Pneumatic

Air pressure requirements

0.8Mpa

Number of cylinders

6–8

Voltage, power

3AC 380V+/-5%, 50HZ

Core size

1000*900*56mm

Running speed

Adjustable

Workstation

1

Production efficiency

60sec.

Maximum size of head plate

120mm

Number of preset models

Non.

Machine weight

2200Kg

Programmable

Non.

Warranty

12 months

Brand name

DAG

Efficiency

About 4-5 Minutes One Core

Safety device

Radiator core builder is equipped with a photoelectric light curtain to protect the safety of the operator

Machine Features:

1. can suitable to different types of tube

2. can adapt to different sizes of cores

3. It has a few types of core builders, for example, condenser core builder machines, intercooler core builder machines, heater aluminum core assembling machines, and water tank core machines.

Servo 3 Rows Aluminum Radiator Core Builder Machine

The servo pneumatic radiator core builder machine is used to assemble radiator cores. The aluminum radiator core builder machine has the advantages of stable and reliable working performance, easy operation, low noise, accurate positioning of flat tube center, and even distribution of fins. The assembled radiator core has a high assembling accuracy and a good appearance, which ensures a better brazing effect in the brazing furnace.

Product SKU: 6

Product Brand: DAG

5

Reviews

There are no reviews yet.