Machine Description

| Machine Name: | Radiator Core Builder Machine | Efficiency: | About 4-5 Minutes One Core |

| Driving Force: | Pneumatic and Servo | Flat Tube Width: | 20-32mm |

| Radiator Layer: | 5 Layers | Overall Dimension: | 2800*2500*1800mm |

| High Light: | Core Builder Machine, Radiator Core Builder Machine With Tube Distribution | ||

Semi-automatic Radiator Core Builder Machine

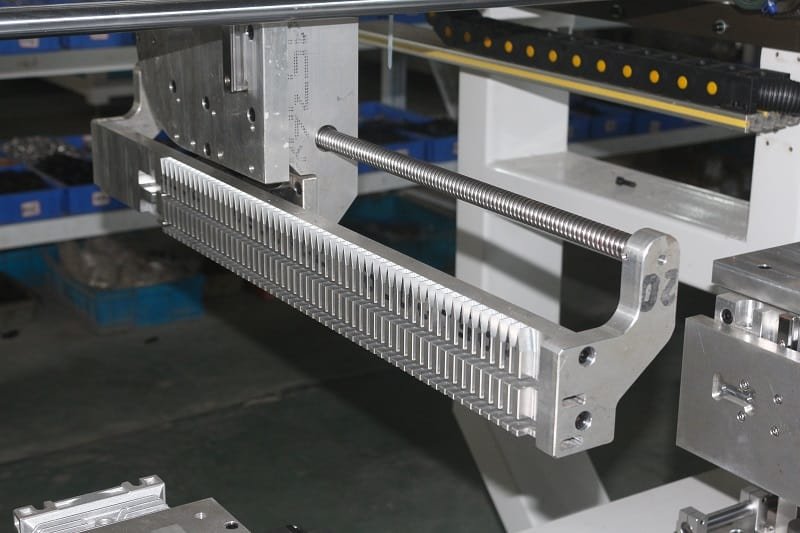

Purpose-built for automotive radiator-core production, the machine delivers stable, low-noise operation with one-button start and HMI-guided set-up. Precision fixtures center each flat tube to ±0.1 mm while servo-driven combs guarantee uniform fin pitch across the entire core width. The result is a dimensionally accurate, visually consistent core that enters the brazing furnace perfectly aligned, ensuring full joint wet-out and maximum braze yield.

Machine Technical Parameters

| Efficiency | About 4-5 Minutes One Core | Safety device | Radiator core builder is equipped with a photoelectric light curtain to protect the safety of the operator |

| Mold | Can customize | Air pressure requirements | 0.6MPa 0.01m3/min |

| Design style | Can customize | Voltage, power | 3P 5-wire, 380V 50Hz ≤13Kw |

| Driving mode | Pneumatics | Running speed | Adjustable |

| Number of cylinders | 6–8 | Production efficiency | 60sec |

| Equipment overall size | 2800*2500*1800mm | Number of preset models | Non |

| Workstation | 1 | Programmable | Non |

| Maximum size of head plate | 120mm | Shape | Unregular |

| Machine weight | 4000kg | After-sale service | Yes |

| Warranty | 12 months | Brand name | DAG |

Semi-automatic Radiator Core Builder Machine – Processable Workpiece Window

| Header-to-header distance | 600-1000 mm; header length: 600-1000mm |

| Fin width | 16, 18, 20, 24, 26, 32mm |

| Fin height | a fixed value (8mm, for example) |

| Flat tube thickness | 2mm |

| Flat tube layer | Five layers |

Semi-automatic Radiator Core Builder Machine – Competitive Advantages

1. Plug-and-play width/height servo: 30-second size change-over, no tools, no re-calibration.

2. ±0.1 mm tube-centering repeatability → zero header-to-tube mismatch, 20 % higher braze yield.

3. Dual-fin magazine + oscillating comb → uniform fin pitch (≤ ±0.2 mm) across 900 mm width, eliminating hot spots in furnace.

4. Low-noise (<65 dB) servo drives and enclosed mechanics – compliant with 8-h workshop noise limits.

5. One-button HMI recipes: store 200 part numbers; automatic adjustment of pitch, clamp force and cycle speed.

6. Manual loading keeps capital cost 60 % below fully automatic line, yet delivers same dimensional accuracy.

7. Quick-swap header & side-plate clamps accept aluminium, copper or stainless parts without extra fixtures.

8. Modular frame allows retro-fit of tube auto-feed or fin pre-stack modules when volume grows.

9. 30 % power savings versus pneumatic machines through servo-only actuation.

10. CE-certified guarding and safety PLC – built for 24/7 two-shift operation with <2 % downtime.

Customizable Semi-automatic Radiator Core Builder Machine

Semi-Auto Core Builder Machines: condenser, intercooler, radiator-aluminium-core and automotive water-tank builders. Quick-change tooling handles any core length/width and accepts diverse tube types—round, oval, flat or micro-port—without retooling delay.

Product SKU: 6

Product Brand: DAG

5

Reviews

There are no reviews yet.