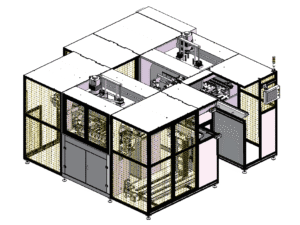

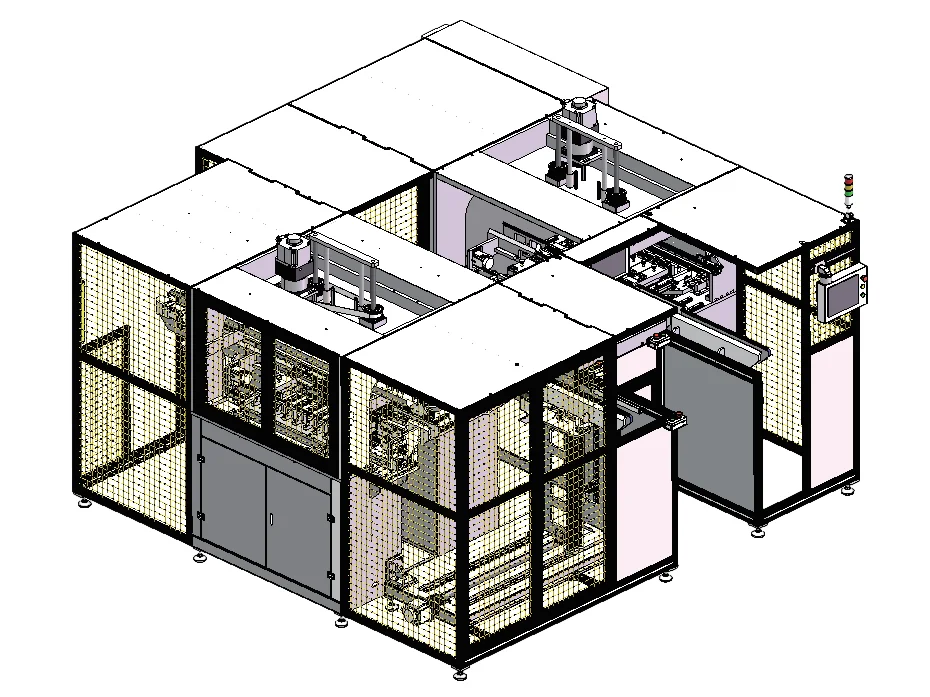

Machine Introduction

Automatic Car Radiator Plastic Tank Crimping Line

Application

Simultaneously crimps plastic tanks, gaskets and headers into a leak-free assembly. Designed for aluminum/plastic radiator cores used in passenger cars, light trucks and commercial vehicles.

Key Process & Hardware Highlights

1. Multi-stage synchronous clinching: long-side clamps arranged in programmable groups (up to 12 sets) execute offset or parallel crimp cycles; short-side clamps driven by dual high-force hydraulic cylinders.

2. Servo-powered flip & shuttle: 1.8 kW closed-loop servo motor provides ±0.1 mm positioning accuracy; auxiliary pneumatic cylinders handle 90° core rotation in <2 s.

3. Two-station close-coupled layout: tank loading → clinching → discharge within 1.2 m operator reach, reducing walk time by 35 % and boosting OEE.

4. Quick-change fixture system: header width adjustment 20–50 mm, automatic locking in <30 s; accommodates 300–1 200 mm core lengths without tooling replacement.

5. HMI recipe control: store 200+ part numbers, automatic clamp-force calculation based on tank material (PA66-GF30, PP-T20, etc.) and gasket thickness.

6. Cycle time: 18–25 s per core (size dependent)

Machine Parameters

Automatic Car Radiator Plastic Tank Crimping Line

| Core height (distance between main boards) | 320mm-800mm |

| Core width (main board length) | 120mm750mm |

| Core thickness (width of main board) | Under 32-80mm |

| Water chamber height | MAX 140mm |

| Compressed air pressure | 0.4mpa--0.7mpa |

| Storage | 500 kinds of water tank parameters,can arbitrary call |

| Power | 380 V、30A |

| Dimension(L×W×H) | 3500× 4000×2300mm |

| Equipment weight | 7(T) |

Global shipment, full customization, on-site commissioning and 24 h technical support—send your RFQ for a free layout and quotation.

Automatic Car Radiator Plastic Tank Crimping Line

The automatic car radiator plastic tank crimping line is used for riveting the plastic water chamber and the main board of the car radiator to integrate the plastic water chamber, the sealing gasket and the main board into one, forming a closed space. The equipment is easy to operate. The two workstations placed in the water chamber are relatively close to each other, with a short movement distance. It can be operated by a single person, offering high efficiency and reasonable prices.

Product SKU: 5

Product Brand: DAG

5

Reviews

There are no reviews yet.