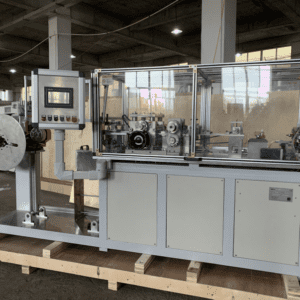

Machine Description

| Product Name: | Radiator Fin Forming Machine | Fin Type: | Radiator Fin |

| Fin Width: | Max 100mm | Fin Height: | 8mm |

| Speed: | 100 M/min | Fin Thickness: | 0.08mm |

| High Light: | 8mm High Radiator Fin Forming Machine, 8mm High aluminium fin press machine | ||

Advantages of Radiator Fin Forming Machine

1. Our standard machine model is the 100m per minute radiator fin-making machine, equipped with a PLC and HMI control system.

2. It is very stable in performance, and the finished product has high efficiency.

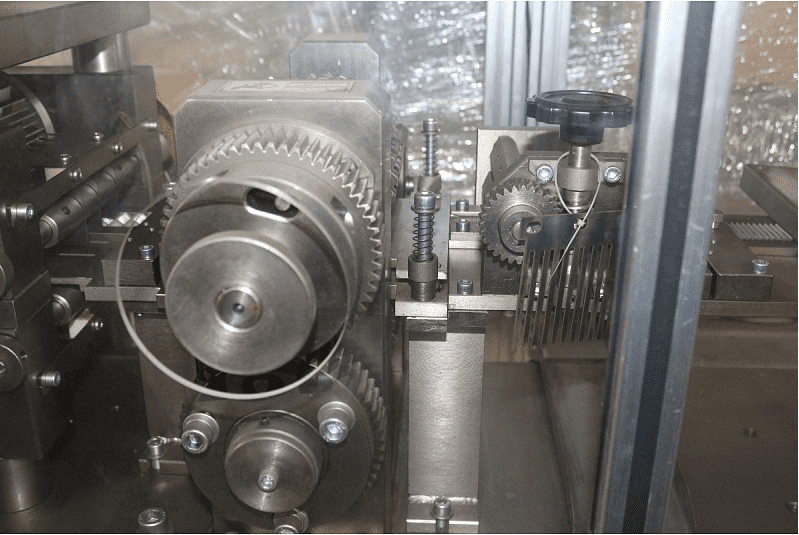

3. The fin forming roller is changeable, and different fin models can be produced on the same machine.

4. The minimum fin thickness for the wavy fin is 0.07mm, saving the customer money.

5. Our patent lubrication system can be equipped with a radiator fin-making machine. The micro spray lubrication system can save about 60% on lubrication.

Specs & Features

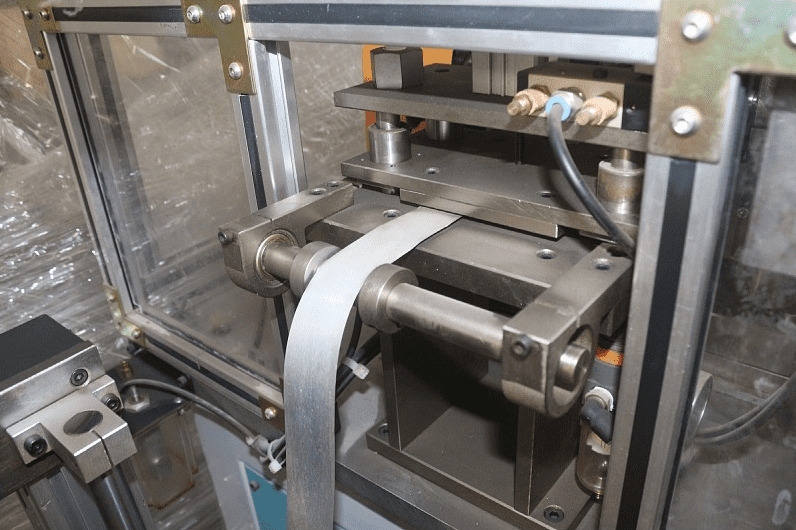

– Un-coiler, dancer tensioner, servo feeder, micro-spray lube, interchangeable fin-form rolls, straightener and flying shear

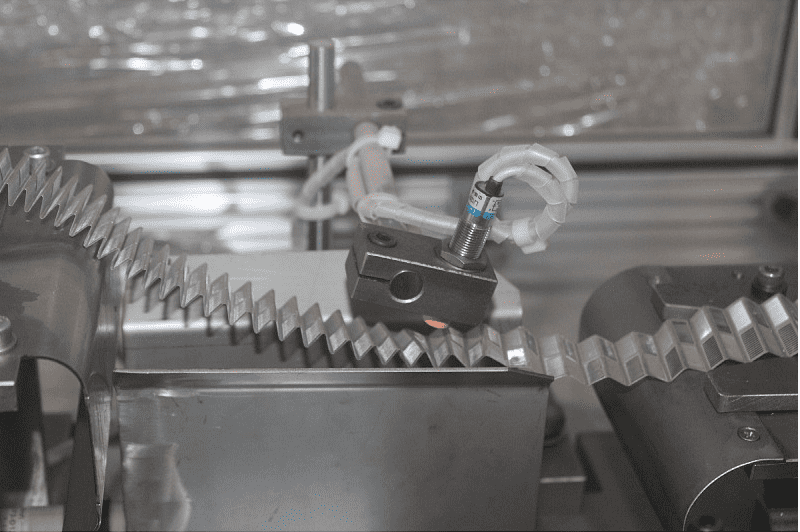

– Full safety suite: strip-out sensor, jam detection, cut-fault alarm, roll-stack overload clutch, beacon stack-light

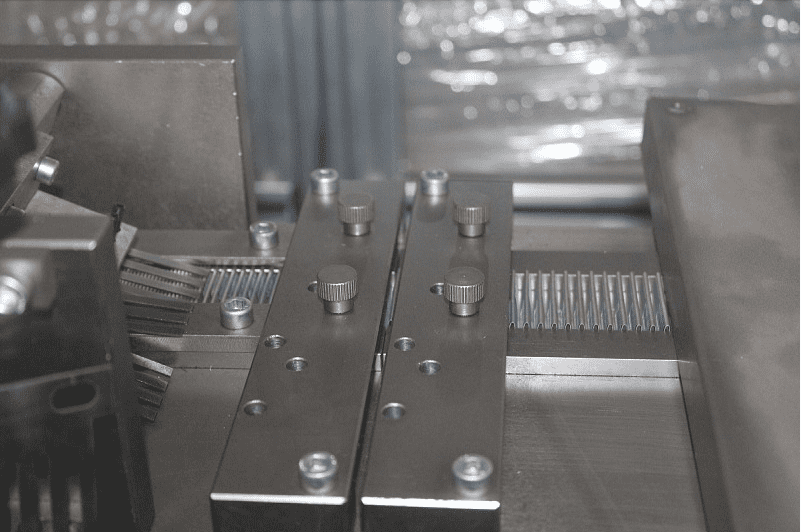

– Fin pitch 1.5–8 mm, height 2–20 mm, aluminum 0.08–0.3 mm—swap cassettes in < 15 min

Machine Technical Parameters

| Power supply | 3Phase, 380V 50HZ |

| Total power | 4.5KW |

| Working speed | 0-100m/min stepless control |

| Fin production efficiency | 1000-4000 fin convolutions per minute; regulation by inverter control; |

| Cutting frequency | max 60 times/ min |

| Protection measure | organic glass cover around the main machine body |

| Cutting accuracy | servo control; ±0 fin; cut at the crest; |

| Equipment Weight | About 1.8Ton |

| Equipment overall size | 4000X900X1800M |

| Air source requirement | air pressure >0.5Mp, Q>0.1m3/ min, dry and cool compressed air |

| Aluminum foil size | ID: 200±20 mm (adjustable);OD: ≤1200mm |

Radiator Fin Forming Machine – Fin Roll Technical Specifications

Aluminum foil width: 16,22, 32,48,56mm;

Fin forming roller type: combined width design;

Fin height: 8±0.05mm;

Fin pitch: 3.5mm;

Aluminum strip thickness: 0.08mm;

Aluminum foil base material: 3003; cladding at one side: 20%;

Aluminum foil temper: H16;

Fin tooling blade material: cobalt-containing high-speed steel forged parts;

Fin tooling blade service life: ≥200 million fin convolutions

Radiator Fin Forming Machine With Combined Width Roller

The aluminum radiator fin forming machine produces heat exchange wavy fins with a combined width fin forming roller. The fin rolling machine has the following devices: decompiler, tensioning device, feeding, micro oil spray lubrication, fin forming, correction, and cutting function. The machine is designed with protections such as strip run-out detection, blockage detection, cutting fault indicator, fin forming unit overloading protection, and fault indication light.

Product SKU: 6

Product Brand: DAG

5

Reviews

There are no reviews yet.