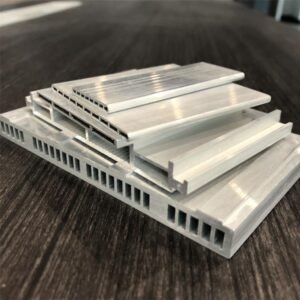

Product Introduction

Aluminum microchannel tube (also called aluminum flat tube or multi-port extrusion) delivers 30 % higher heat-transfer efficiency versus traditional round pipe. 3003-modified alloy + high-frequency welding guarantees zero leak under 12 MPa burst pressure—ideal for EV battery cooling, HVAC-R condenser, and charge-air intercooler.

Product Specifications

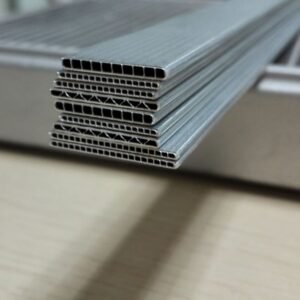

1. Alloy & Temper: 3003-H24 / 3102-H24 / 6063-T5

2. Port Geometry: 8×0.5 mm, 10×0.4 mm, 12×0.35 mm (custom CNC cut)

3. Wall Tolerance: ±0.02 mm, Porthole die ≤0.08 mm seam gap

4. Coating: Zinc-sprayed (7–15 μm) or chromate-free anti-corrosion layer

5. Length: 200–3000 mm, burr-free saw cut, deburred R0.1 mm

6. Standards: GB/T 6892, ASTM B221, ISO 14001, RoHS, REACH, DFMEA available

7. Package: Standard Exportable Wooden Box

Product Application

1. EV thermal management: battery cold plate, chiller, power-module baseplate

2. HVAC-R: R290/R32 microchannel condenser, evaporator coil

3. Energy storage: liquid-cooling plate for 280 Ah LiFePO4 pack

4. Industrial: inverter heat sink, wind-turbine transformer cooler

FAQ

Q1: Microchannel aluminum tube vs. round tube heat transfer difference?

A1: 30 % higher HTC (heat-transfer coefficient) thanks to hydraulic diameter <0.5 mm and interrupted fin design.

Q2: Can you supply clad aluminum microchannel tube for CAB brazing?

A2: Yes, 4343/3003/7072 tri-layer clad, 4 % Si layer, melting range 607–613 °C.

Q3: Minimum bending radius?

A3: 1.5×tube height with mandrel, no crack at 10× magnification.

Premium Aluminum Microchannel Tube

China OEM aluminum microchannel tube 3003 alloy, porthole extrusion, high-frequency welding. For EV battery cooling, HVAC-R condenser, R290/R32 ready. • One-Stop Design and Manufacturing Solutions • Advanced Manufacturing Capabilities • Custom Non-Standard Sizes Available • Standard Existing Sizes to Save You Initial Costs • Quick Ship Standard Aluminum Tube Sizes Welcome to Place Your Professional Order

Product SKU: 99999

Product Brand: DAG

5