Product Introduction

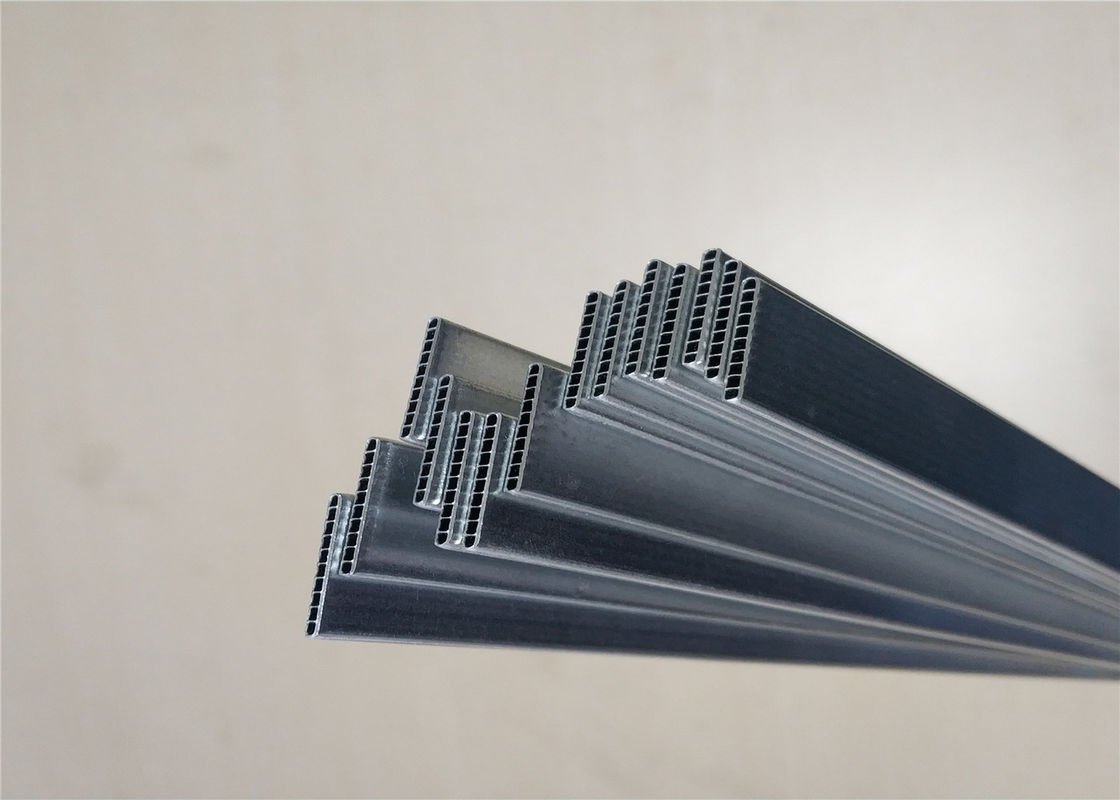

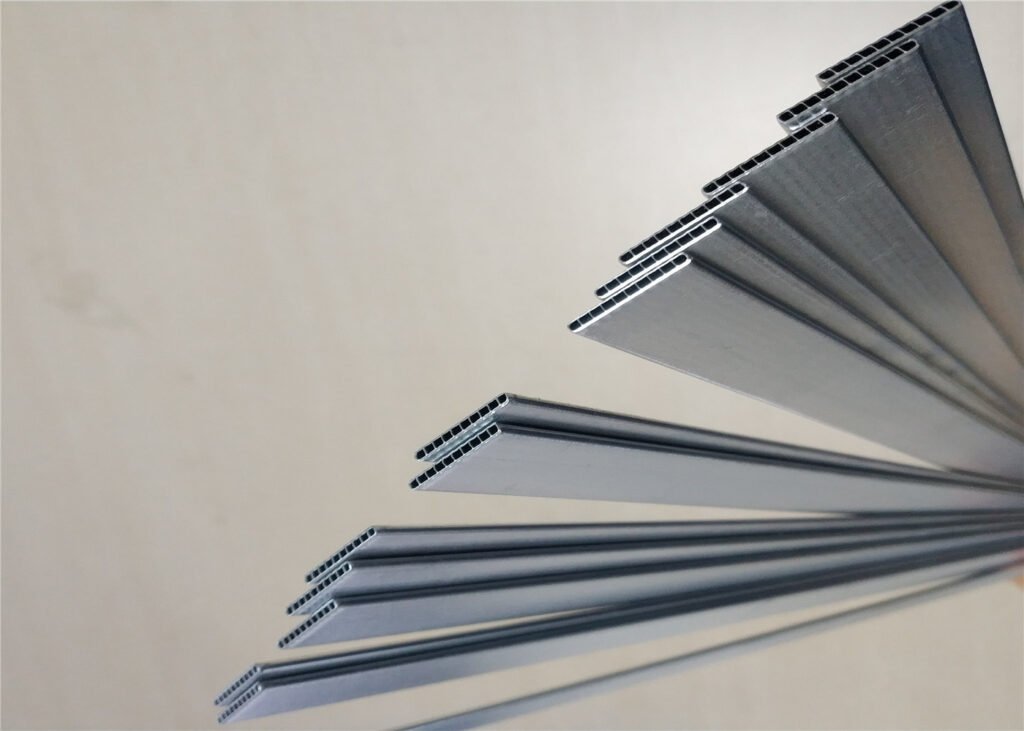

Extruded Microchannel Aluminum Flat Tubes

Precision-extruded from high-grade AA3003/AA3103 alloy, these seamless micro-channel flat tubes are engineered for next-generation automotive accessories—oil coolers, battery chillers, power-electronics cold plates and auxiliary condensers.

Microchannel Tubing, also known as Multi-Porous Extrusion (MPE), is a highly refined, premium quality product with the following characteristics:

• Low energy costs High performance

• Low space and weight

• High corrosion and pressure resistance

• High recycling value

• Low refrigerant charge

Product Key Features

Extruded Microchannel Aluminum Flat Tubes

1. Hydraulic diameter as low as 0.4 mm and port counts 6–90 to match any heat-load requirement

2. Zn-diffusion or clad 4343/4045 layers available for >1 000 h SWAAT corrosion resistance

3. Wall tolerance ±0.02 mm, width/flatness ≤0.05 mm—perfect for CAB or NOCOLOK® brazing without fin bridging

4. Burst pressure ≥18 MPa at 250 °C, guaranteeing durability in R-1234yf and high-voltage coolant circuits

5. Electrophoretic or epoxy coating optional for extra salt-spray protection on exposed surfaces

Supply Options

1. Standard widths 8 mm – 32 mm in 0.2 mm increments, custom die ready in 10 days

2. Level-wound spools to 300 kg or cut-lengths 200 mm – 6 m, deburred and capped

3. Laser-etched QR traceability for full lot, alloy and temper tracking

Our Aluminum Microchannel Tubes can be used in a wide range of radiator/transmission applications. The material can be 1050/1060/1070/3003/3102 or as per the customer’s requirement.

We can do many sizes, such as 4.0×0.5mm, 6.0×1.0mm, 7.0×1.0mm, 7.94×1.0mm, 8×1.0mm, 9.52×1.0mm, 10×1.0mm, 12.7×1.2mm, 15.88×1.2mm, 16.0×1.0mm, 9.05×1.5mm or customized according to non-standard.

Certifications & Performance

Extruded Microchannel Aluminum Flat Tubes

ISO/TS 16949, ASTM B491, SAE J2670 compliant; thermal conductivity ≥190 W m⁻¹ K⁻¹; leak rate <1 × 10⁻⁹ Pa·m³ s⁻¹ helium test.

Extruded Microchannel Aluminum Flat Tubes

We start production from aluminum ingots and implement strict quality control; all parts are produced in-house for price advantage. • Sample orders are accepted; • Free samples for your quality check; • High cost performance, fast delivery time; • Good communication skills, quality service and detailed customized solutions

Product SKU: 99999

Product Brand: DAG

5