Machine Description

| Machine Name: | Intercooler Core Assembly Machine | Working Principle: | Semi-automatic Operation; Tube Dispenser |

| Machine Mechanism: | Servo and Pneumatic Type | Time Needed For 1 Core: | About 3.5 Mins One Core |

| Machine Size: | 2500*2300*1800mm | Machine Weight: | 2800kg |

| High Light: | Radiator core builder machine, Intercooler core assembly machine | ||

Intercooler Core Assembly Machine Introductions:

- The aluminum core assembly machine’s auto-setting head plate can assemble the flat tubes, fins, headers, and side plates in one working cycle and then form a radiator core.

- In particular, the machine can also expand the tube end automatically when assembling the header.

- The radiator core assembly machine combines the mechanical, servo, and pneumatic systems with manual operation to assemble the radiator core.

Machine Technical Parameters

Technical Parameters of Aluminum Intercooler Core Assembly Machine

| Core Dimension | Core height direction | 350-780mm |

| Core width direction | 200-680mm | |

| Flat Tube Layers | One layer/2layers | |

| Tube Laying Mode | Double working position | |

| Flat Tube Flaring Mode | Automatic /Manual | |

| Fin Laying Mode | By fin tray /Manual | |

| Production Capacity | Around 40sets/hour | |

| Drive Mode | Servo and Pneumatic | |

| Overall Dimension | 2500*2300*1800mm | |

| Weight | 2800kg | |

Technical Parameters of Aluminum Radiators

| radiator fin height: 8.03mm |

| core diagonal line tolerance:±1mm |

| Core height: ±1mm, core width: ±1.5mm |

| Distance between fin end and header plate: 2±1mm (could be adjusted through the positioning block). |

| equipment mechanical movement time: 55s |

| According to the customer’s requirement, the assembly table is preserved with an aluminum fixture hole. |

| Safety device: photoelectric light curtain to protect the safety of the operator. |

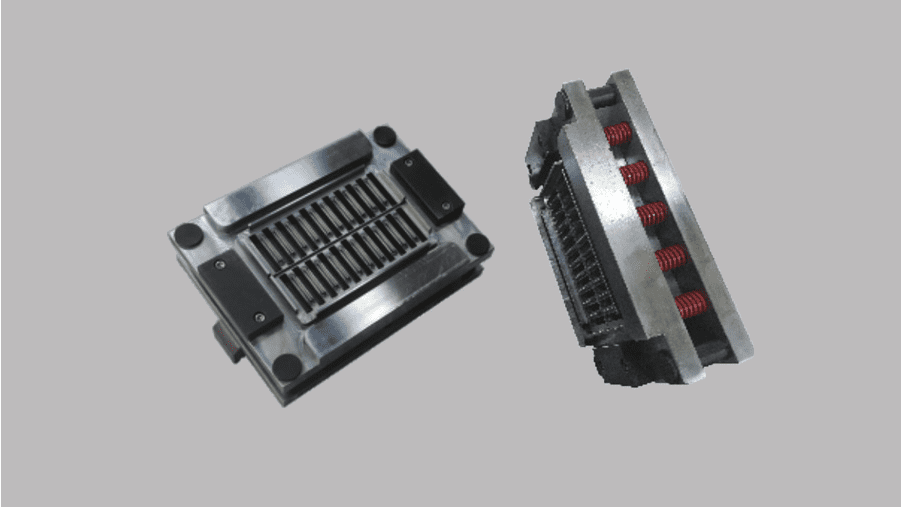

The main parts of the machine

The intercooler core assembly machine is mainly comprised of a header mold, side plate positioning block,

core clamping mechanism, flat tube silo, flat tube distribution mechanism, comb teeth mechanism,

driving mechanism, work table, work table up-down mechanism, and electrical control system.

PLC Intercooler Core Assembly Machine

The intercooler core assembly machine consists of a left and right header positioning fixture, tube end expansion device, tube storage box, tube distribution device, tube guidance device, tube guidance screw, assembling working table, flat tube and fin positioning device, tube distribution up-down platform, core body compression mechanism, pneumatic system, and electrical system. The core assembly machine combines the mechanical, servo, and pneumatic system with a screw adjustment to assemble the radiator core.

Product SKU: 6

Product Brand: DAG

5

Reviews

There are no reviews yet.