Machine Description

Automatic Inner Aluminum Fin Insertion Machine

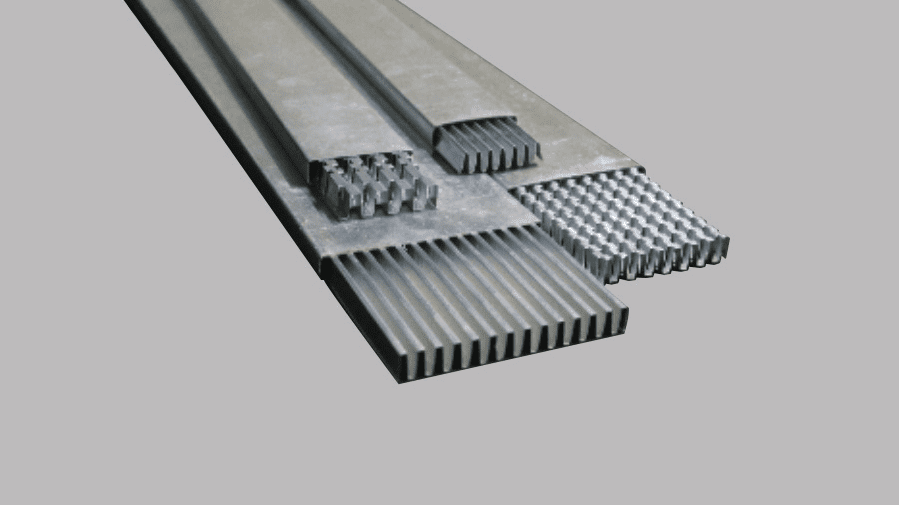

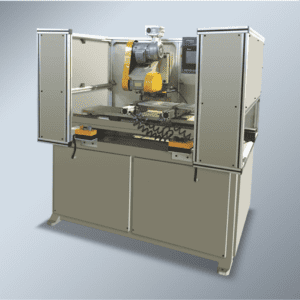

This integrated system comprises a tube magazine, precision fin feeding conveyor, flaring station, and automated insertion mechanism. Designed for seamless synchronization with fin forming machines, it executes the complete inner fin insertion process automatically. The fin count per insertion cycle is dynamically determined by flat tube length specifications.

1. Machine Type: Automatic Inner Fin Inserter for Heat Exchanger Production

2. Core Components: Tube hopper, fin conveyor, flaring device, insertion head

3. Integration: Direct interface with fin forming machines

4. Process: Automated feeding, positioning, and insertion of internal fins

5. Variable Insertion: Fin quantity adjustable based on tube length parameters

6. Applications: Automotive radiators, HVAC coils, condensers, evaporators

Machine Technical Parameters

Automatic Inner Aluminum Fin Insertion Machine

| Work Piece specification | Design per specification |

| Production capacity | Calculate per length |

| Drive mode | Servo+Pneumamtic |

| Overall dimension | 4200*1800*1800mm |

| Weight | 2.2 T |

Automatic Inner Aluminum Fin Insertion Machine

This automated system precisely inserts pre-formed fins (from fin forming machines) into flat aluminum tubes, forming the core structure of heat exchangers. The machine integrates a tube magazine, precision fin feeding conveyor, hydraulic flaring station, and servo-driven insertion mechanism for continuous, synchronized operation with upstream fin forming equipment. Applications: Automotive radiators, condensers, evaporators, charge air coolers, HVAC coils

Product SKU: 3

Product Brand: DAG

5

Reviews

There are no reviews yet.