Product Introduction

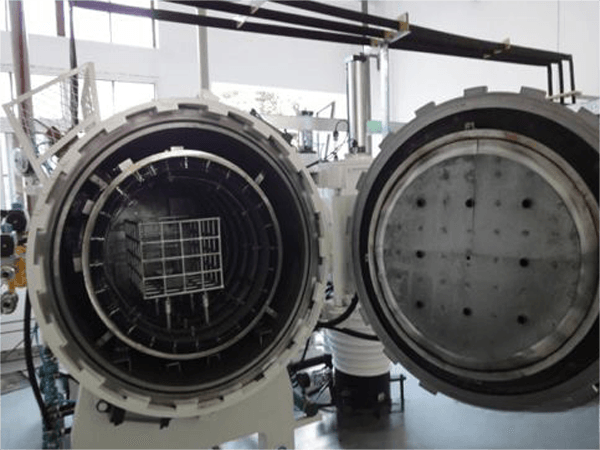

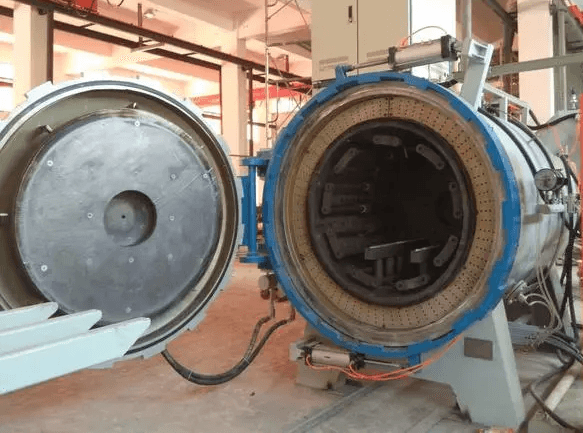

Horizontal Vacuum Nitrogen Protection Brazing Furnace

A horizontal vacuum brazing furnace, combining both vacuum and inert gas shielding technologies, is an industrial device specifically designed for high-quality joining of precision metal components (such as aluminum heat exchangers and automotive radiators).

Operation Introduction

Vacuum furnace brazing produces high-quality welds with minimal workpiece deformation. The process involves applying flux to the cleaned and decontaminated workpieces where they are to be welded, followed by the application of solder (powder, granular, or flake form). The other part to be welded is placed on top (also fluxed on the joining surface). The two parts are then positioned and placed in a furnace, heated to the melting point of the solder. The welding process raises the workpiece temperature within the furnace, melting the solder, which has a lower melting point than the workpiece, ultimately achieving the desired weld.

Horizontal Vacuum Nitrogen Brazing Furnace Operation Procedure

Place the cleaned workpiece into the furnace rack → Close the furnace door to evacuate → Turn off the vacuum pump and flush with nitrogen → Heat to the desired temperature, then turn off the heat → Remove the workpiece from the heating chamber to allow for rapid cooling → Cool to approximately 170°C before removing the workpiece.

Industry Applications

The main function of the horizontal vacuum brazing furnace is to provide a high-temperature, clean, high-vacuum environment in which to perform high-temperature degassing and welding on test pieces. It is primarily used for high-temperature vacuum degassing and welding of small and medium-sized precision metal parts. It is particularly suitable for high-temperature vacuum brazing of metal materials such as titanium alloys and stainless steel.

Automotive Manufacturing

Brazing of aluminum plate-fin heat exchangers and air conditioner evaporators, achieving zero contamination and less than 0.5 mm deformation.

Precision Electronics Cooling

Suitable for radar waveguides and server liquid cooling plates, achieving 0.05 mm microchannel sealing.

Affordable Vacuum Brazing Furnace for Sale

The horizontal vacuum nitrogen protection brazing furnace is used for non-corrosive brazing and periodic brazing of 6 series, 3 series, and 1 series aluminum alloys. It can also be used for high-temperature vacuum brazing of titanium alloys, stainless steel and other metal materials. We can customize our equipment to meet your needs and budget at competitive prices. We welcome your inquiries and look forward to establishing long-term partnerships with you.DAG Worldwide Radiator Machinery Exporter.

Product SKU: 3

Product Brand: DAG

5