Machine Description

| Machine Name: | Radiator Making Machine | Speed: | Direct Push-over And Rolling For Wavy Non-teeth Header |

| Aluminum Tube: | Tube Straightening And Cutting Machine | Straightened And Cut Per Time: | 2 Pipes |

| Flat Aluminum Tube Width: | 14-32mm | Control: | PLC/HMI |

| High Light: | Radiator manufacturing equipment, radiator tube-making machine | ||

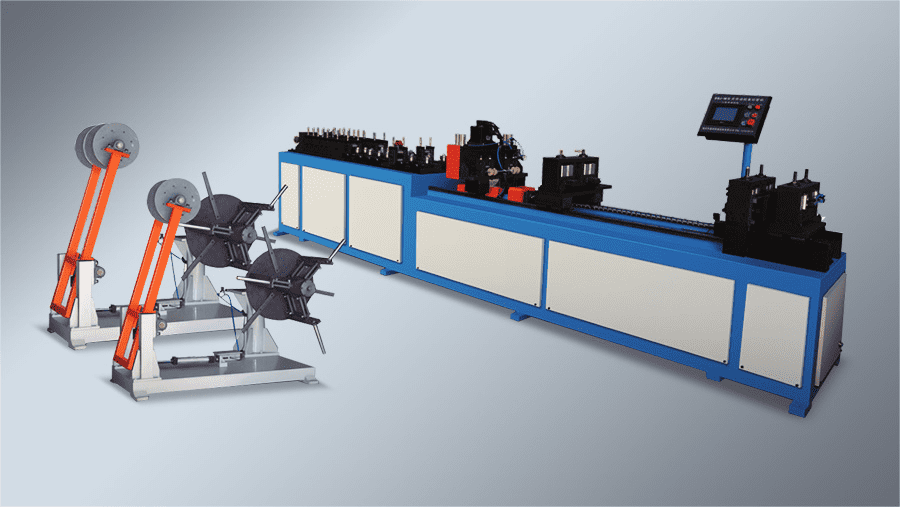

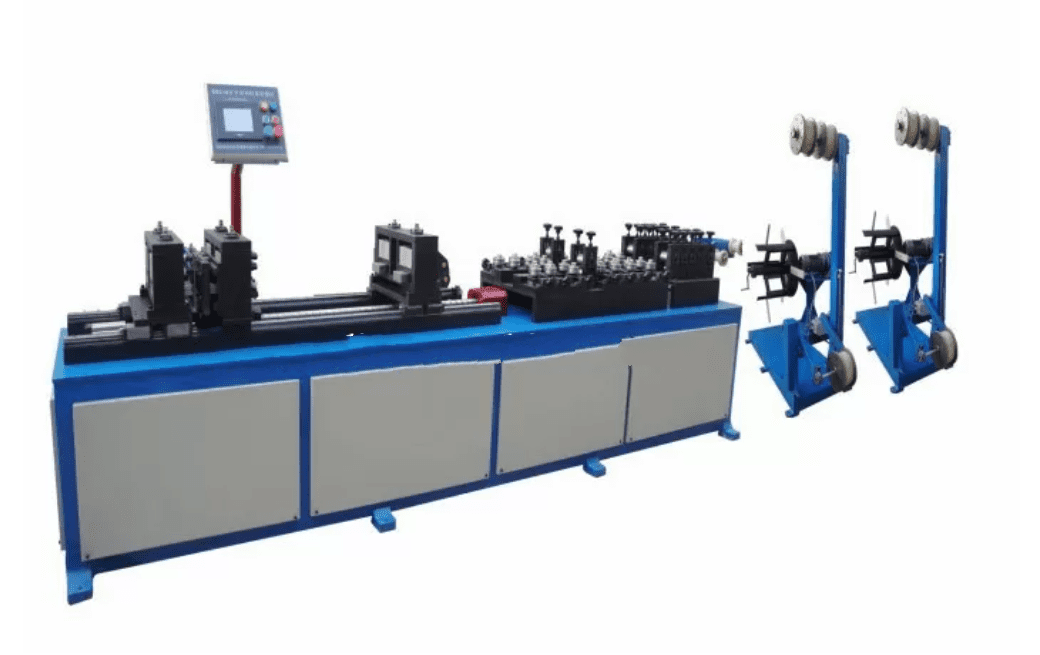

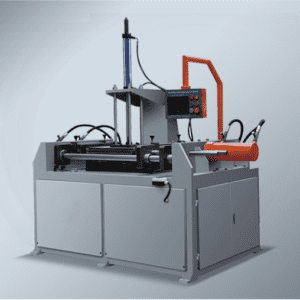

Harmonica Tube Straightening and Cutting Machine

This advanced automated production line is specialized for processing coiled flat tubes (harmonica tubes) through integrated straightening, calibration, precision cutting, and end-necking operations, delivering uniform tube segments with automated dimensional control.

Core Technical Features

1. Control Architecture: Full CNC automation with PLC control and HMI touchscreen interface for seamless parameter programming

2. Dimensional Versatility: Cutting length and tube width are independently adjustable via servo-controlled settings

3. Straightening Module: Cartridge-style quick-change design enables rapid die replacement without tools

4. Drive System: High-performance servo motors paired with precision ball screws for accurate positioning and feeding

5. Cutting Technology: Dual-mode configuration: Rotary disc cutting or Wire cutting for optimized edge quality

6. Necking Mechanism Servo-driven end-forming station with programmable necking depth and taper

7. Tooling Flexibility: Quick-exchange clamping fixtures allow processing of multiple tube specifications on the same platform

8. Performance Metrics: Cutting precision: ±0.1mm; High-speed operation; Simplified user operation; Streamlined material changeover

Operational Excellence

1. Superior Accuracy: Servo-controlled feeding ensures consistent dimensional repeatability across high-volume production

2. Rapid Throughput: Optimized cutting cycles maximize production efficiency

3. User-Friendly Interface: Intuitive controls minimize training time and operator intervention

4. Minimal Downtime: Tool-free quick-change systems reduce changeover time to under 10 minutes

Target Applications

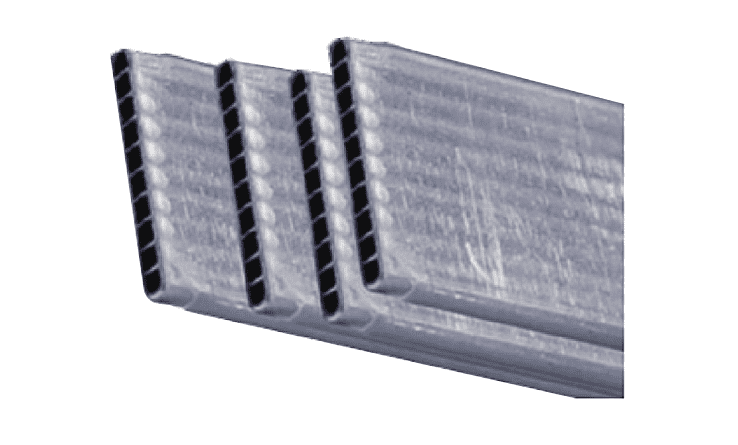

Aluminum micro-channel tubes, heat exchanger flat tubes, condenser/evaporator tubing lines.

Machine Technical Parameters

Automatic Harmonica Tube Straightening and Cutting Machine

| Production rate | 2.5 seconds per time (based on cut-to-length at 650mm) |

| Pipes are to be straightened and cut per time | Two pipes |

| Flat aluminum tube thickness | 1-3mm |

| Flat aluminum tube width | 14-32mm |

| Cut-to-length | larger than 100mm |

| Feeding length of the aluminum pipe | 200-900mm (twice or multiple charges to cut the aluminum tube when the cut-to-length is very large) |

| Length straightening accuracy <±0.2mm | |

| Width straightening accuracy | ±0.04mm/850nn |

| Thickness straightening accuracy | ±0.02/850mm |

| Replacement time of coils | 3min |

| Preparation time for cutting tubes with different width | ≤15min |

| Cutting knife replacement time | ≤5mins |

| Air source pressure | 0.6Mpa |

| Equipment weight | 2.8T |

| Main Machine dimension | 4500×850×1300mm (the area length is 15m if the decompiler is included.) |

| Decoiler overall dimension | 1400×1300×1800mm ( 2 sets) |

This automatic Harmonica tube straightening cutter is ideal for HVAC, automotive heat exchanger, and micro-channel tube manufacturing. With CNC-controlled length/width adjustment, servo ball screw transmission, and rapid tool change capabilities, the machine optimizes production efficiency while maintaining ±0.1mm cutting precision. The modular design supports quick fixture replacement for diverse harmonica tube specifications, making it a versatile solution for high-volume precision tube processing.

Fully-automatic Uncoiler Machine

- Coil inner diameter: 450-500mm;

- width: 300-330mm;

- decompiler bearing weight: 300kg;

- Decoiler motor power: 0.75kw

Automatic Aluminum Harmonica Tube Straightening and Cutting Machine

This automatic Harmonica tube straightening and cutting machine is engineered for precision processing of aluminum micro-channel tubes in HVAC and automotive heat exchanger manufacturing. Featuring servo-driven straightening and cutting modules, quick-change cartridge dies, and programmable necking capabilities, the system achieves ±0.1mm cutting accuracy with production speeds up to 60 meters per minute. The rapid fixture exchange system enables seamless transitions between tube specifications, maximizing Overall Equipment Effectiveness (OEE) for harmonica tube processing, micro-channel tube production, and heat exchanger coil manufacturing operations.

Product SKU: 2

Product Brand: DAG

5

Reviews

There are no reviews yet.