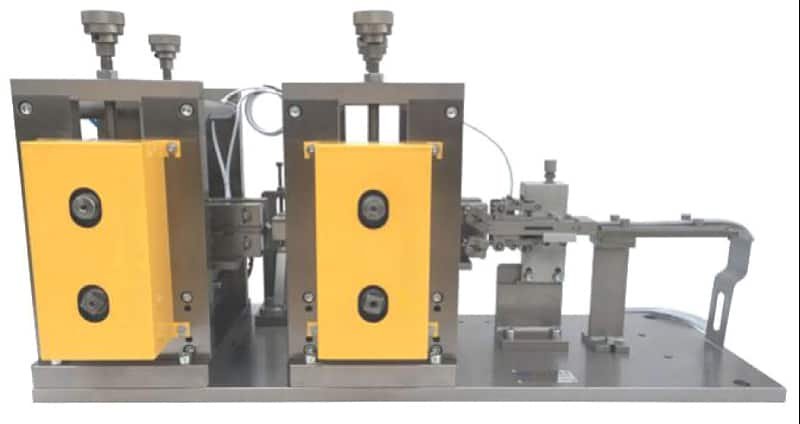

Machine Description

| Tray Weight: | Max 500kg | Material Tray: | Double Tray |

| Servo System: | Panasonic | Fin Material: | Aluminum Thickness 0.05-0.20mm |

| Fin Width: | 12-56mm (customized) | Fin Height: | 3~22mm |

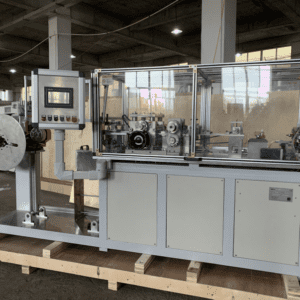

| Fin Length: | Customer Defined | Overall Dimension: | 5105×1200×2180(mm) |

| Machine Weight: | About 4.6 Tons | Inlet Fuel Injection System: | Japanese Precision |

| Power Supply: | AC 3-380V±10% | Power Frequency: | 50HZ±2% |

| Power Supply Power: | 17KW | Pressure: | P/0.6mp (dry, Cool And Filtered Compressed Air) |

| High Light: | 300M/Min radiator fin machine, Double tray radiator fin machine,300M/Min aluminum fin machine | ||

300M/Min Aluminum Fin Machine corrugated aluminum fin machine

The equipment adopts eight axes and eight sets of servo controls to produce stable and high speed, improve output, increase benefits, and realize automated production.

Machine Technical Parameters

| Item | Parameters |

| Feed speed | Maximum speed 300m/min (related to peak numbers)Stable speed 280m/min |

| Cut off frequency | The maximum cutting speed is 120cuts / min (the cutting frequency is related to the fin cutting length and the number of peaks) |

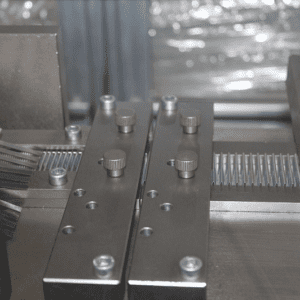

| Cutting accuracy | ± 0 peak, all cut at the peak top |

| The inner diameter of the tray | φ150mm~φ200mm (expandable 300mm) |

| The outer diameter of the tray | ≦φ1800mm |

| Tray weight | Max 500kg |

| Material tray | Double tray |

| servo system | Panasonic |

| fin material | Aluminum thickness 0.05-0.20mm |

| Fin width | 12-56mm (customized) |

| Fin height | 3~22mm |

| Fin length | Customer Defined |

| Overall dimension | 5105×1200×2180(mm) |

| Machine weight | About 4.6 tons |

| Inlet fuel injection system | Japanese precision |

| Power Supply | AC 3-380V±10% |

| Power frequency | 50HZ±2% |

| Power supply power | 17KW |

| pressure | P/0.6mp (dry, cool, and filtered compressed air) |

| flow | Q>0.1㎥/min |

| Equipment color | 6109 white(according to the color sample requirements provided by customers) |

| Remarks | It can be customized according to special needs |