Product Introduction

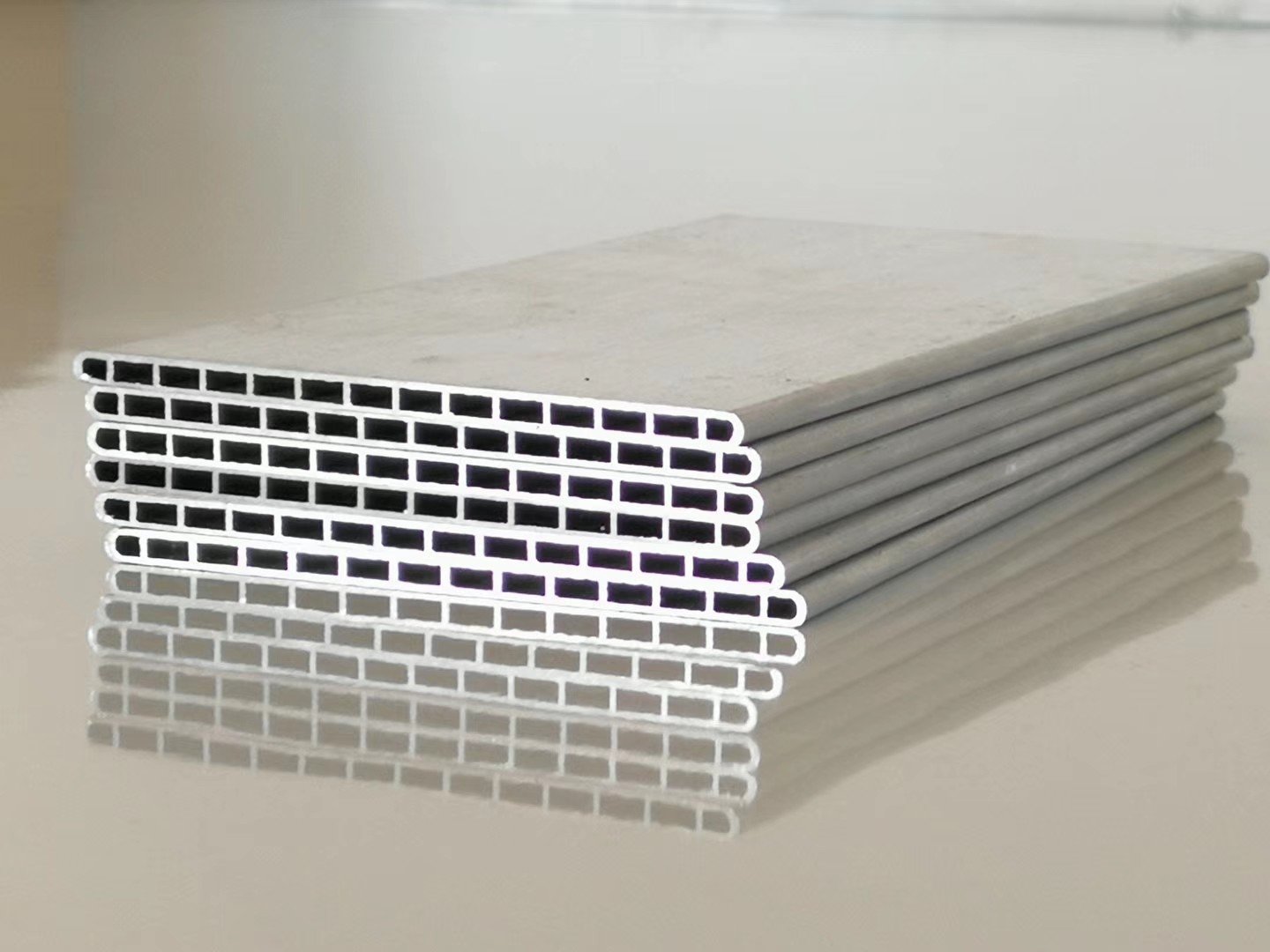

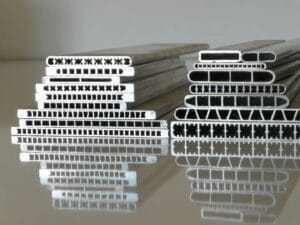

Radiator Aluminum Microchannel Flat Tube

Compared to traditional circular tubes, aluminum microchannel flat tubes (industry aliases: multi-hole extruded tube, flat multi-port tube, MPE tube) have increased internal fins and channel interfaces, thereby improving the overall heat transfer coefficient (HTC) by ≥30% and reducing energy consumption by 15%.

Product name: Aluminum microchannel flat tube

Size: Customized

Application: Radiator industry

Material: Aluminum alloy

Color: Silver

Surface: Polished

Product manufacturing technology

Aluminum Microchannel Flat Tube

1. Ultra-large extrusion ratio

The extrusion ratio refers to the ratio of the cross-sectional area of the aluminum tube before hot extrusion to the cross-sectional area of the aluminum tube after extrusion, which is generally 8 to 50 times, while the cross-sectional area of the microchannel aluminum tube is only about 4px2. The extrusion ratio must reach more than 400 times, which is more than 8 times the limit process of aluminum extrusion.

2. Ultra-high dimensional accuracy

The dimensional accuracy of the microchannel aluminum tube is much higher than the national standard of “Hot Extrusion Tubes for Research on Aluminum and Aluminum Alloys”. According to the national standard, the dimensional deviation of a typical variety with a width of 16mm is ±0.3mm, while the width deviation of the microchannel aluminum tube is ±0.03mm, and the high requirements even need to be increased to ±0.01~±0.02mm.

3. Airtightness

A set of microchannel heat exchangers has about 50 to 150 microchannel aluminum tubes. As long as there is an airtight defect (such as pores, inclusions, etc.), the entire air conditioner will be scrapped. Therefore, its quality standard is measured in PPM (parts per million), and the measurement standard is below 15PPM.

4. High-quality bars

The minimum wall thickness of the microchannel aluminum tube is only 0.13mm. If the purity and hydrogen content of the cast rod material do not meet the requirements, as long as there are very fine pores or inclusions, the thin-walled microchannel aluminum tube will leak. Therefore, high-purity refined rods with a hydrogen content of less than 0.09% must be used.

5. Surface zinc spraying technology

Since there is a refrigerant medium in the microchannel aluminum tube and atmospheric corrosion outside, it is very easy to leak due to pitting. A thin layer of zinc must be sprayed on its outer surface to protect the tube wall from corrosion. At present, there is no qualified zinc spraying equipment manufacturer in China, and only a very small number of manufacturers can provide it internationally.

6. Online flaw detection and testing technology

Due to the difficulty of microchannel aluminum tube technology, how to use scientific and effective online flaw detection, surface quality and other testing methods in the production process to timely discover (mark) defective products is very critical to the quality control of microchannel aluminum tubes.

Affordable Radiator Aluminum Microchannel Flat Tube

DAG aluminum microchannel flat tube is made of refined aluminum ingot extrusion, Fully customizable, affordable price, global shipping.Welcome to Place Your Professional Order! We have good cooperation experience with big customers all over the world; Fast delivery time; Acceptable sample order; High cost performance; Good communication skills, good service and understanding of customers.

Product SKU: 99999

Product Brand: DAG

5