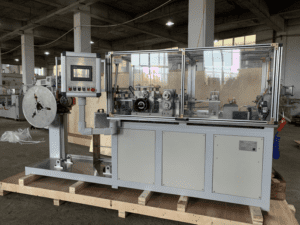

Machine Description

| Name: | Radiator Fin Machine | Fin Material: | Copper |

| Speed: | 100 M/min | Working Principle: | Fin Rolling Mechanism |

| Weight: | About 1.8Ton | Copper Material: | H62 |

| High Light: | Copper Radiator Fin Forming Machine, PLC Radiator Fin Forming Machine, Fully Automatic Radiator Fin Making Machine | ||

Copper Radiator Fin Forming Machine

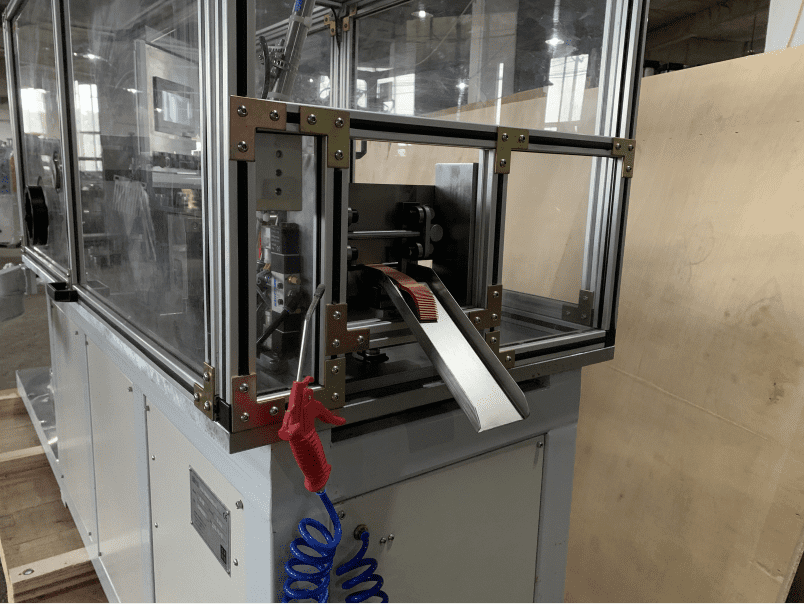

Copper radiator fin forming machines are specialized industrial equipment engineered for the automated production of copper plate heat sink fins. These high-performance systems automatically fabricate and precisely cut copper fins according to preset specifications and programmable dimensions.

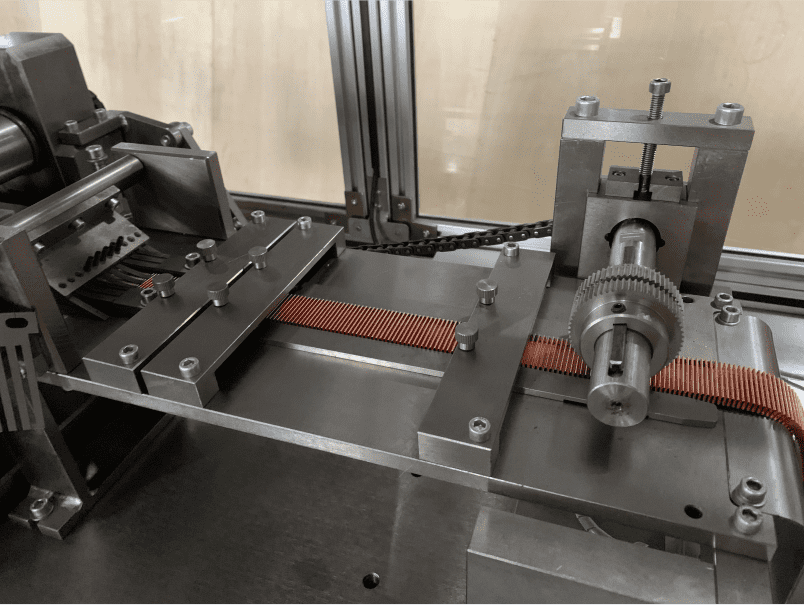

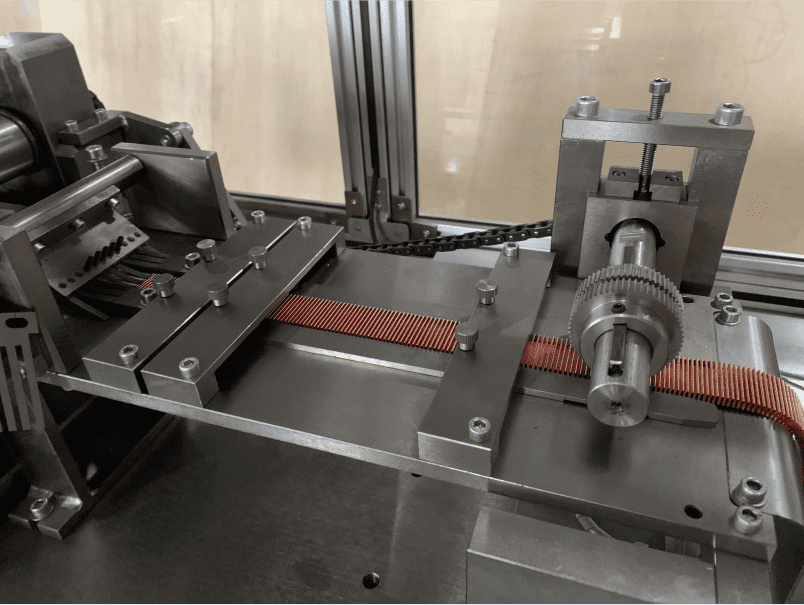

The copper radiator fin forming machine integrates seven primary functional modules:

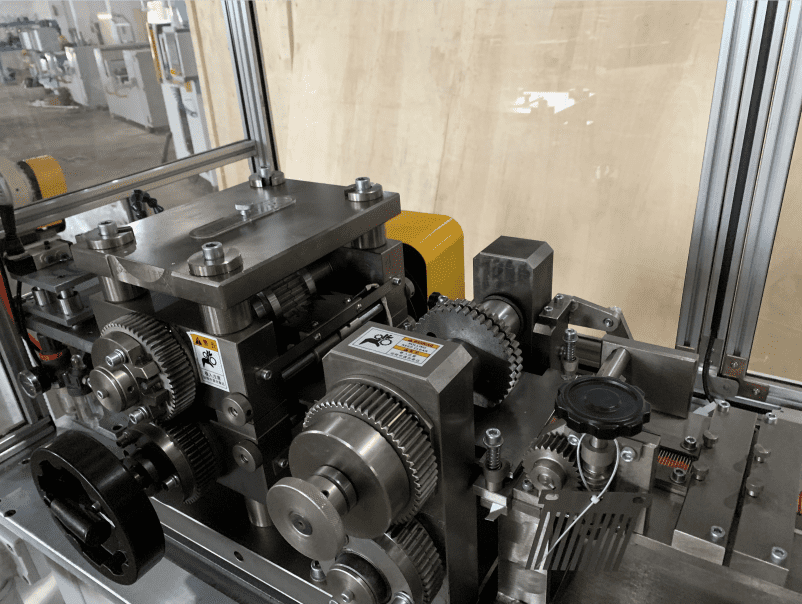

1. Drive Unit – Provides controlled power transmission for continuous operation.

2. Edge Folding Device– Precision bends and forms fin edges for optimal thermal contact.

3. Die Forming Unit – Shapes copper sheets into standardized fin profiles using customized molds.

4. Counting Device – Automated piece counting and batch tracking system.

5. Cutting Unit– High-precision shear mechanism for burr-free cutting.

6. Sheet Collection System – Automated stacking and material handling.

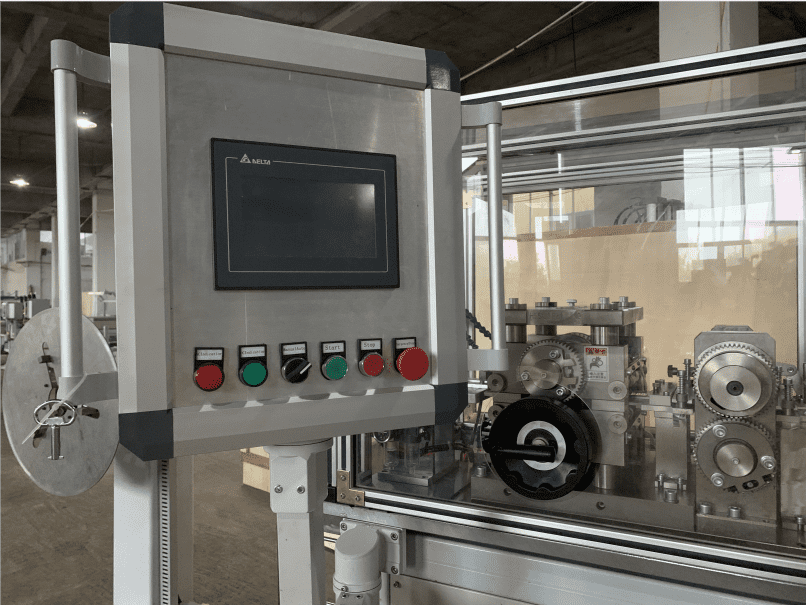

7. Electrical Control System – PLC-based control with HMI interface for parameter management.

Machine Technical Parameters

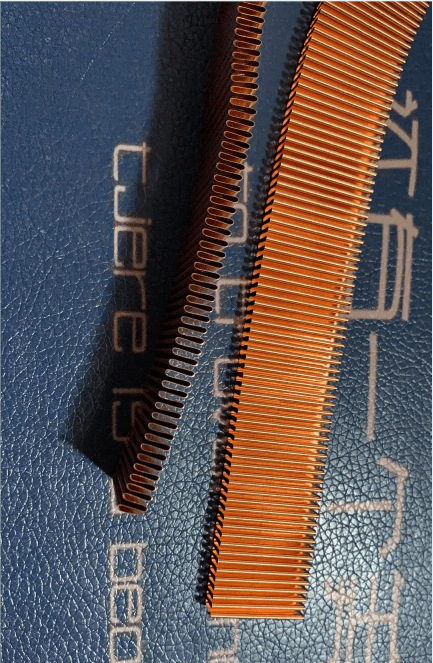

| Fin Size produced by radiator fin forming machine |

| 1-Fin material: H62, thickness: 0.07-0.08mm; |

| 2-Hole-to-hole distance: 15.88mm; |

| 3- Row-to-row distance: 17.53mm; |

| 4-Tube hole size:1.93mm*15.95mm; |

| 5- Max width of the fin: 143mm; |

| Technical Parameters of radiator-making machine |

| a) running speed: 0-40m/min; |

| b) cutting frequency: 0-60 times per min; length of plate: adjustable (stepless regulation); |

| Components List of radiator fin forming machine | ||

| No. | Item | Q’ty |

| 1 | Main working table | 1 set |

| 2 | Fin rolling tool | 1 set |

| 3 | Automatic cutting device | 1 set |

| 4 | Inverter | 1 set |

| 5 | Servo motor | 1 set |

| 6 | PLC | 1 set |

| 7 | Touch screen | 1 set |

| 8 | Electrical control system | 1 set |

| 9 | Other electrical components | 1 set |

PLC Car Copper Radiator Fin Forming Machine

This fin forming machine is specifically designed for the high-volume production of copper flat fins used in heat sink assemblies. The precision-engineered dies enable multi-process forming, including louver or convex rib patterns, perforation punching, and edge hemming operations. Integrated servo-driven positioning technology delivers exceptional accuracy, ensuring consistent cutting precision and tight tolerance control throughout the production cycle. High-performance automotive copper radiator fin forming machines at competitive prices. 100% customizable to your specs. Contact us for a free quote today!

Product SKU: 6

Product Brand: DAG

5

Reviews

There are no reviews yet.