Product Description

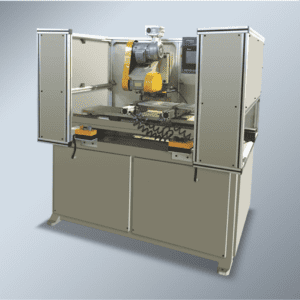

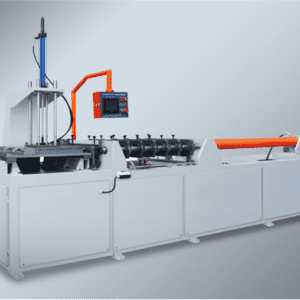

Car Radiator and Condenser Leak Tester

This precision sealing integrity test system is purpose-built for condenser and radiator leak detection applications. Utilizing compressed air pressure as the test medium, the unit executes differential pressure measurements through integrated high-accuracy sensors, real-time digital displays, quick-connect fixture plugs, programmable time relays, and pneumatic solenoid valves. Each automated work cycle completes a comprehensive pressure differential analysis to accurately detect micro-leaks in radiator assemblies.

The dual-station design enables simultaneous testing of two products, delivering exceptional throughput for high-volume production. This high-efficiency solution is extensively deployed in condenser and radiator manufacturing facilities, proven to enhance manufacturing productivity and product quality standards through reliable, repeatable testing performance.

1. 7-Inch High-Resolution Touchscreen HMI – Intuitive graphical interface for seamless operation and real-time monitoring

2. Ultra-High Precision Detection – 1 Pa differential pressure resolution for identifying minute leaks

3. Multi-Channel Programming – 32 parameter sets for rapid product changeover and recipe storage

4. Dual Operating Modes – Manual debugging mode and fully automatic production mode

5. Self-Cleaning Pneumatic Circuit – Automatic purge function prevents contamination and ensures test repeatability

6. Comprehensive Data Export – RS232 serial interface and USB flash drive direct write capabilities

7. Industrial Integration Ready – Abundant remote I/O terminals for seamless PLC connectivity or direct control of external devices (solenoid valves, alarms, marking systems)

8. Extensive Data Logging – 12,000-test memory capacity with date/time stamping for full traceability

9. Universal Compatibility – Configurable for testing multiple radiator core models and sizes

Product Parameters

-Aluminum Condenser and Radiator Leak Tester –

Differential pressure type leakage test

| Essential pressure sensor | Resolution display | 0.1Pa |

| Sensor measuring range | 0~±2000Pa | |

| Sensor tolerated pressure | 13.8MPa | |

| Sensor error | 0.065%FS | |

| Direct pressure sensor | Resolution display | 0.1kPa |

| Measuring range | Qc100 Model:3~100kPa | |

| Qc300 Model:5~300kPa | ||

| Qc600 Model:5~600kPa | ||

| Qc1000 Model 50~1000kPa | ||

| Qc4000 Model:50~4000kPa | ||

| Sensor tolerated pressure | Three times the Pressure if the sensor is in full-scale | |

| Sensor error | ±1%FS | |

| Display unit | Test Pressure | kPa、kg/cm2、PSI、mbar、bar、Torr、mmH2O、mmHg |

| Leakage amount | Pa、Pa/s、mL/s、mL/min |

Direct pressure leakage tester

| Direct pressure sensor | Resolution display | 0.1 kPa |

| Measuring range | 0.0-20MPa | |

| Sensor tolerated pressure | Three times the pressure if the sensor in full scale | |

| Sensor error | ±1%FS | |

| Display unit | Test Pressure | kPa、kg/cm2、PSI、bar、mbar、torr、mmHg、mmH2O |

| Leakage amount | kPa、kg/cm2、PSI、bar、mbar、torr、mmHg、mmH2O、mL/min | |

| Leakage&test pressure upper limit | 20MPa | |

Flow leakage tester

| Flow sensor | Resolution display | 0.001mL/min |

| Display range | 0~999.9999mL/min | |

| Sensor tolerated possum | 0.7MPa | |

| Leakage upper limit | 200.00L/min | |

| Sensor error | ±1%FS | |

| Direct pressure sensor | Resolution display | 0.1kPa |

| Sensor measuring range | 0~600kPa | |

| Sensor tolerated pressure | ±1%FS | |

| Sensor error | Three times the Pressure if the sensor is in full-scale | |

| Display unit | Test Pressure | kPa、kg/cm2、PSI、bar、torr |

| Leakage amount | mL/min、mL/s、sccm、m3/h | |

| Pressure test range | 5~600kPa | |

| Data channel number | 32 groups(0~32) | |

| Display Refresh number | 20Hz | |

| Testing Cycle Time setting | 0~999 seconds, test time 1800 seconds | |

| Power | AC220V±10%,50Hz | |

| Test pressure source | Clean, dry air, pressure between 100kPa and 600kPa | |

| Environment temperature | Working temperature 5~40℃ Storage temperature-20~70℃ | |

Car Radiator and Condenser Leak Tester

This precision sealing integrity test system is purpose-built for condenser and radiator leak detection applications. Utilizing compressed air pressure as the test medium, the unit executes differential pressure measurements through integrated high-accuracy sensors, real-time digital displays, quick-connect fixture plugs, programmable time relays, and pneumatic solenoid valves. Each automated work cycle completes a comprehensive pressure differential analysis to accurately detect micro-leaks in radiator assemblies. Engineered and manufactured by DAG Company, Shenzhen, China. Fully customizable configurations available with detailed process engineering and professional technical support. Factory-direct pricing with reliable worldwide logistics and installation services. Inquire today—receive competitive quotations within 24 hours.

Product SKU: 10

Product Brand: DAG

5

Reviews

There are no reviews yet.