Product Overview

Precision Car Aluminum Radiator Header Plates

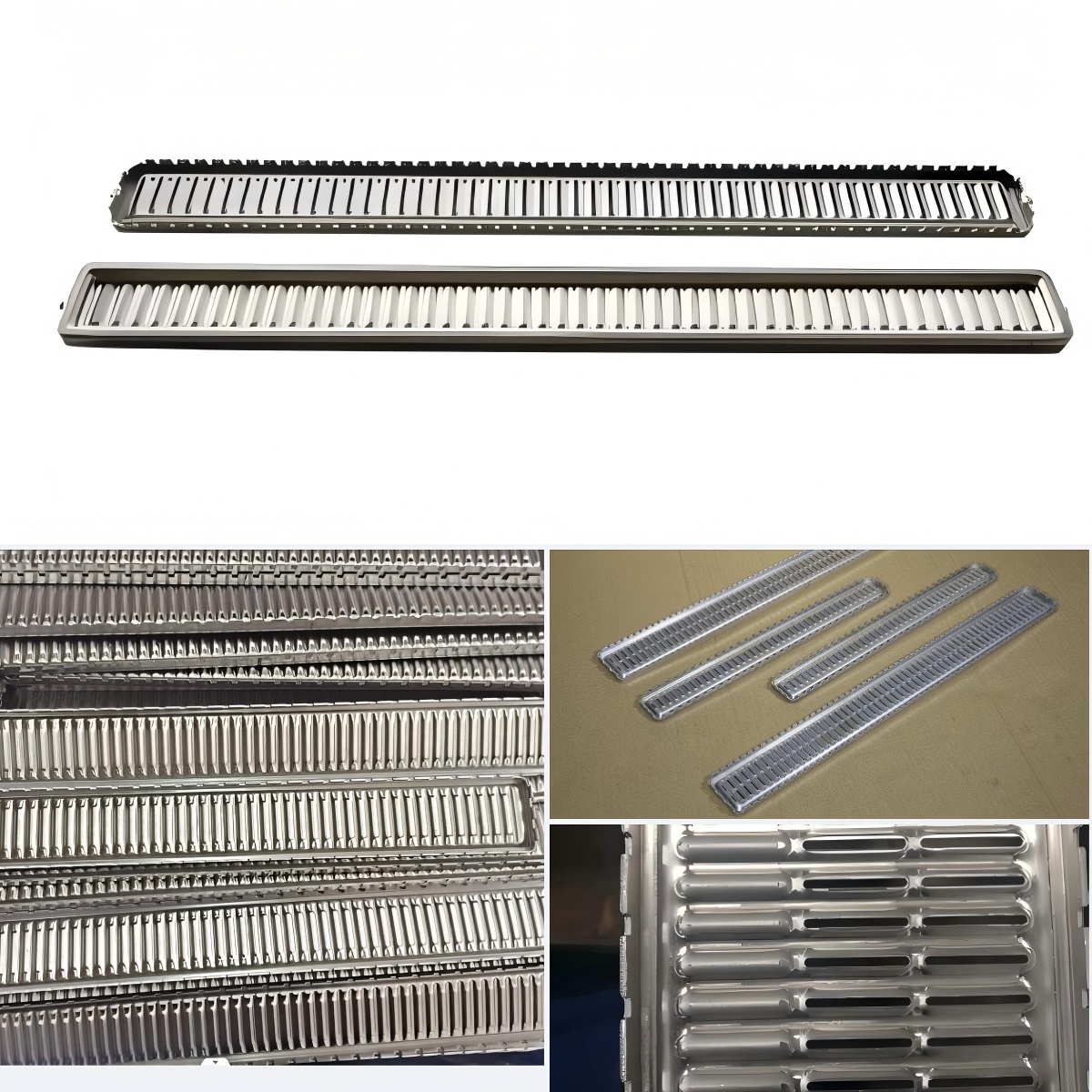

Car Aluminum Radiator Header Plates are critical structural components that serve as the primary sealing interface between radiator core tubes and plastic/aluminum tanks in automotive cooling systems. Manufactured through precision CNC stamping processes, these plates ensure leak-proof performance under high-pressure coolant circulation. Engineered for universal compatibility with 2-row, 3-row, and 4-row radiator configurations, they provide OEM-grade reliability for passenger cars, commercial vehicles, and performance applications.

Key Features & Benefits

Precision Car Aluminum Radiator Header Plates

Superior Material Properties

1. Material Grade: Premium 3003 aluminum alloy with optional 4343/3003/7072 multi-layer clad composite

2. Hydrophilic & Anti-Corrosion: Specialized alloy composition provides excellent corrosion resistance and superior brazing characteristics

3. Lightweight Design: 40% weight reduction vs. steel alternatives, improving fuel efficiency and handling

4. Surface Treatment: Hard anodized finish (25-30μm) with protective coating for extended service life

Multi-Row Universal Compatibility

1. Single Pattern Design: One header plate accommodates 2-row, 3-row, and 4-row radiator cores

2. Staggered Tube Slots: Precision-engineered geometry ensures proper tube alignment across all row configurations

3. Reinforced Structure: Internal ribbing prevents deflection under high pressure (rated to 4.0 bar)

4. Optimized Flow: Internal channels promote equal coolant distribution for maximum cooling efficiency

Precision Manufacturing

1. CNC Stamping: High-precision dies ensure ±0.05mm dimensional accuracy

2. Burr-Free Finish: Advanced processing eliminates sharp edges, preventing assembly damage and ensuring worker safety

3. Uniform Punching: Consistent hole spacing and TAB heights guarantee seamless core integration

4. Flatness Control: ≤0.2mm per 100mm length for perfect tank sealing

Technical Specifications

Precision Car Aluminum Radiator Header Plates

1. Materia: 3003-H14 Aluminum Alloy (4343/3003/7072 clad optional)

2. Thickness: 1.5mm (custom: 1.4mm, 1.8mm, 2.0mm, 2.5mm)

3. Temper: H14 (O, H12, H16 available)

4. Width Range: 100mm – 1400mm (fixed dimension)

5. Length Range: 100mm – 6000mm

6. Row Compatibility: 2-row, 3-row, 4-row (single pattern)

7. Tube Pitch: 22mm standard (16mm, 26mm customizable)

8. Aperture/Tolerance: 26mm ±0.1mm (customizable)

9. Surface Finish: Mill finish / Hard anodized + hydrophilic coating

10. Operating Pressure: Rated 4.0 bar (burst pressure: 12-15 bar)

11. Temperature Range: -40°C to 180°C continuous

12 Tensile Strength: ≥165 MPa

13. Yield Strength: ≥140 MPa

14. Flatness: ≤0.2mm/100m

Performance Characteristics

1. Corrosion Resistance: 720+ hours salt spray (ASTM B117) – 5+ year service life

2. Pressure Cycling: 100,000 cycles @ 0-4.0 bar – Zero leak failure

3. Thermal Shock: 500 cycles -40°C to 180°C – No cracking or deformation

4. Dimensional Accuracy: ±0.05mm tolerance – Perfect tube-to-plate fit

5. Brazing Quality: 100% brazed joint inspection | Reliable leak-proof seal

6. Hydrophilic Properties: Contact angle <10° – Enhanced condensation drainage

Applications

Precision Car Aluminum Radiator Header Plates

1. Universal Fit: Compatible with all car brands and models when custom fabricating radiator assemblies

2. Common Applications:

– Japanese: Toyota Camry/Corolla, Honda Accord/Civic, Nissan Altima

– American: Ford F-150/Mustang, Chevrolet Silverado, Dodge RAM

– European: VW Passat, BMW 3/5 Series, Mercedes C/E-Class, Audi A4

– Korean: Hyundai Sonata, Kia Optima

Customized Aluminum Radiator Header Plates

This radiator plate is a high-quality aluminum radiator core plate with adjustable dimensions and excellent heat dissipation performance, making it a versatile and reliable choice for your cooling system needs. For custom specifications or technical consultations, please provide your radiator core drawings or sample plates for rapid quotation. Free Samples. Low MOQ. Factory-Direct Pricing. Affordable Price. Request a Quote Today.

Product SKU: 99999

Product Brand: DAG

5