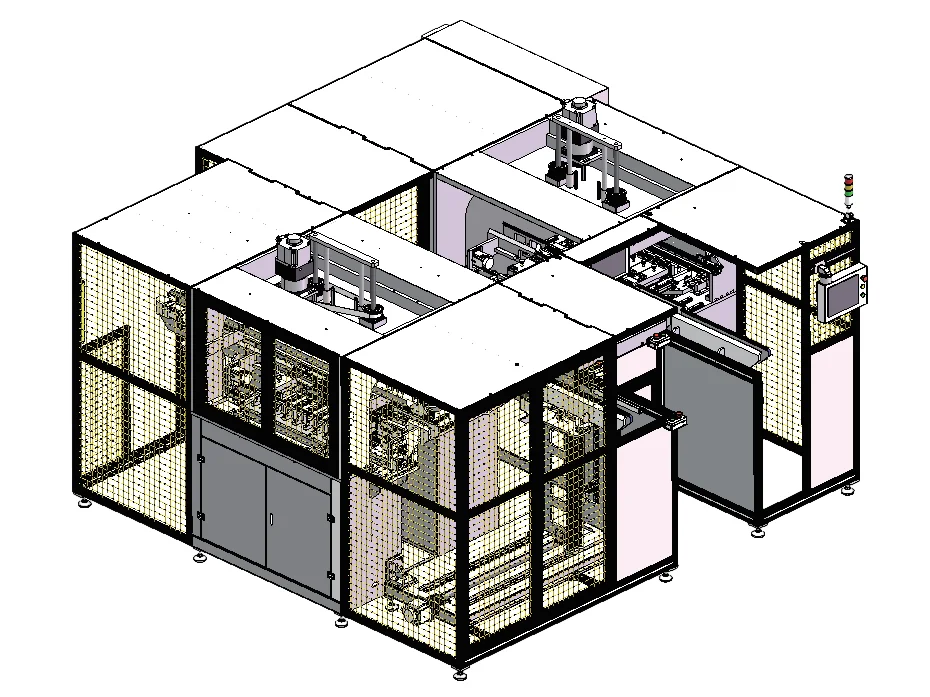

Machine Introduction

The equipment is used for riveting the plastic tank and main board, to synthesise the plastic tank, gasket and main board to form a confined space. The long side buckle adopts a multiple-group integral pressure design, and the buckle manipulator is divided into multiple groups, which can be dislocated or buckled at the same time. The short-edge manipulator is powered by the cylinder. The core flip and transport use the servo motor as the main power, and the cylinder is the auxiliary power. The equipment is simple to operate, the distance between the two stations in the water discharge chamber is short, the movement distance of the operation staff is short, and the benefit is high.

Machine Parameters

| Core height (distance between main boards) | 320mm-800mm |

| Core width (main board length) | 120mm750mm |

| Core thickness (width of main board) | Under 32-80mm |

| Water chamber height | MAX 140mm |

| Compressed air pressure | 0.4mpa--0.7mpa |

| Storage | 500 kinds of water tank parameters,can arbitrary call |

| Power | 380 V、30A |

| Dimension(L×W×H) | 3500× 4000×2300mm |

| Equipment weight | 7(T) |

Reviews

There are no reviews yet.