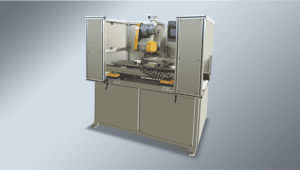

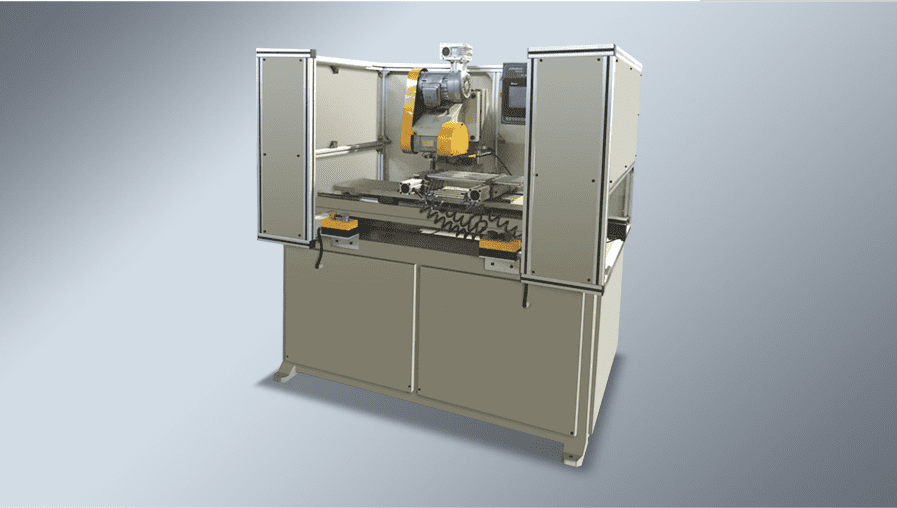

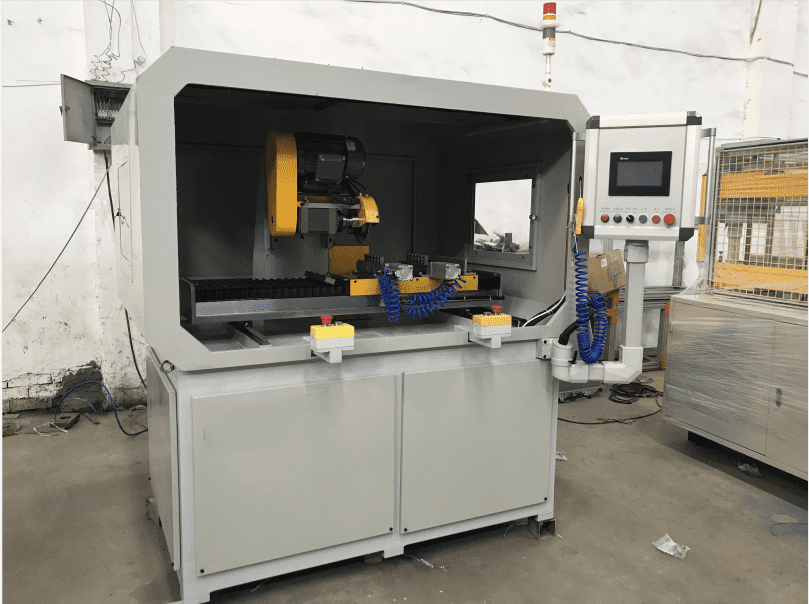

Machine Description

Automatic Header Tube Slotting Machine

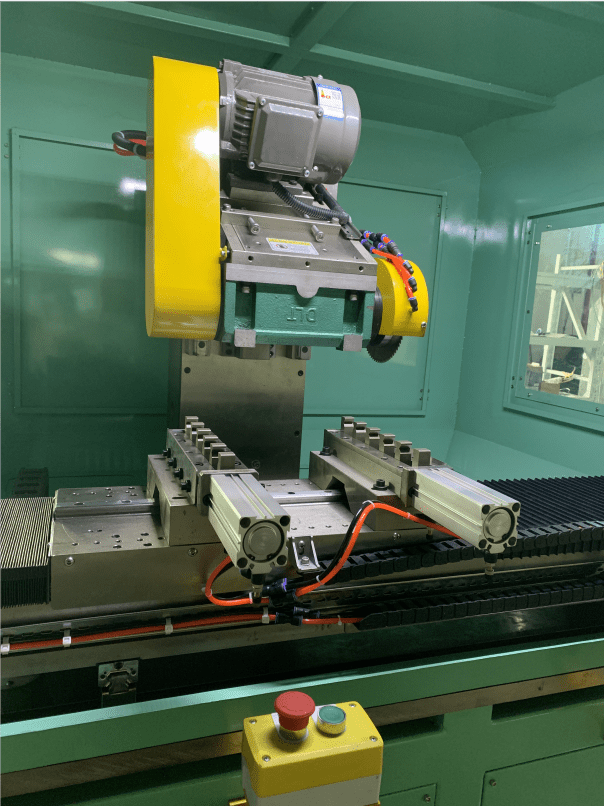

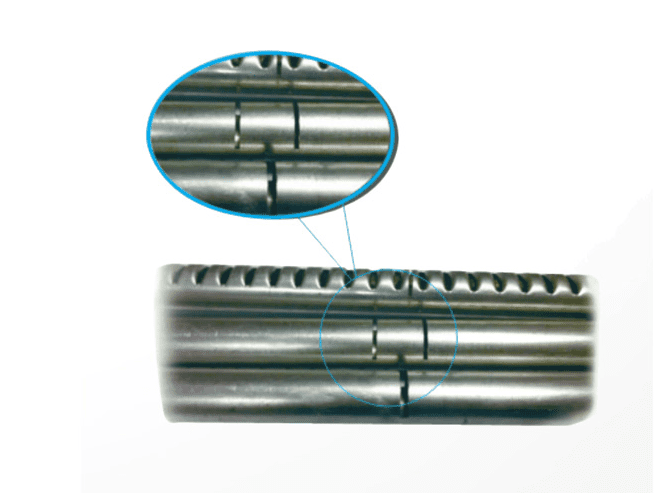

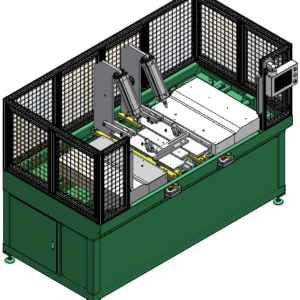

This specialized machine performs automated slotting operations on header tube baffles for heat exchanger manufacturing. The system executes a complete automated cycle: precision clamping via fixed positioning blocks, automated tube feeding, high-speed slotting, and automatic return positioning.

Core Performance Features

1. High-Precision Slotting: Tight tolerance machining with exceptional cut location accuracy

2. Rapid Cycle Times: High-speed cutting boosts production throughput

3. Superior Surface Finish: Produces smooth, burr-free slot surfaces

4. Secure Clamping: Robust positioning blocks firmly lock header tubes during machining

Technical Capabilities

1. Quick-Change Positioning Blocks: Accommodates various tube diameters and slot configurations

2. Dedicated Slotting Process: Engineered specifically for cutting cross-sectional slots in tube baffles

3. CNC Programmable Control: Precise slot positioning and repeatable production quality

Machine Technical Parameters

Header Tube Slotting Machine

| Workpiece specification | D Type/Round Type Manifold Pipe |

| Baffle Hole | as per the customer’s requirements |

| Slot quantity | Customer setting |

| Precision tolerance range | Per customer’s requirements |

| Pipe Processed per time | 1-5 pcs/time |

| Operation method | Manual loading-Auto cutting-Manual unloading |

| Production capacity | Around 600 pcs/Hour |

| Drive mode | Servo/Pneumatic |

| Overall dimension | 1800*1500*1700mm |

| Weight | 1.5 T |

Automatic Header Tube Slotting Machine

This specialized equipment is engineered for precision slotting of tubular components, specifically designed for cutting cross-sectional slots in pipes for heat exchanger and condenser manufacturing. Essential equipment for parallel flow condenser production lines, automotive heat exchanger manufacturing, and HVAC manifold processing.

Product SKU: 6

Product Brand: DAG

5

Reviews

There are no reviews yet.