Machine Introduction

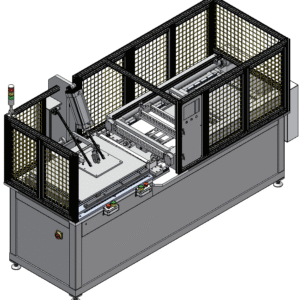

Automatic CNC Tube Bending Machine

This integrated system processes coiled aluminum tubes through a complete automated workflow: decoiling → precision straightening → CNC bending → end necking → high-speed cutting, producing finished bent tube assemblies with consistent dimensional accuracy.The system enables direct program storage and editing for rapid changeover between different tube specifications.

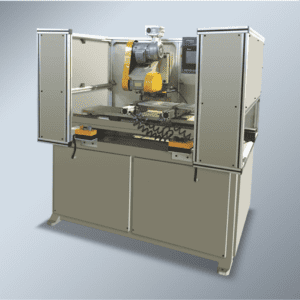

Technical Capabilities

1. Multi-Profile Flexibility: Processes various flat tube profiles using interchangeable quick-change dies

2. Programmable Data Storage: Direct parameter storage and one-touch recall for production efficiency

3. Hybrid Drive Architecture: Combines pneumatic clamping, electrical controls, and high-precision servo-driven bending

4. Continuous Operation: Fully automated sequence control for uninterrupted production cycles

Application Summary

This automatic tube bender is engineered for aluminum flat tube processing in heat exchanger manufacturing, automotive condenser production, and HVAC component fabrication. Featuring servo-controlled precision bending, integrated decoiling-to-cutting workflow, and programmable tooling setups, the machine delivers high-volume production of complex bent tubes with ±0.2mm accuracy. The rapid die changeover system and onboard data storage maximize Overall Equipment Effectiveness (OEE) and production flexibility for harmonica tube, micro-channel tube, and refrigeration line applications.

Machine Technical Parameters

Fully Automatic CNC Tube Bending Machine

| Workpiece specification | As per the customer’s requirements |

| Workpiece size | As per the customer’s requirements |

| Flat tube specification | Thickness: 1-3mm |

| Width: 12-32mm | |

| Max bend quantity | 50 bend |

| Flat tube material plate size | Inner diameter: minimum 400mm |

| Outer diameter: maximum 1200mm | |

| processing quantity | One piece/time |

| Decoil/Feeding/Cutting | Automatic |

| Straightening/Bending | Automatic |

| Lubrication type | Automatic |

| Production speed | Around 230 pcs/shift(as per actual workpiece dimension) |

| dynamics type | Servo+pneumatic |

| Machine overall size | 6000*1300*1700mm |

| Machine weight | 2.5 T |

Automatic CNC Tube Bending Machine for Aluminum Flat Tubes

This automatic tube bender is engineered for aluminum flat tube processing in heat exchanger manufacturing, automotive condenser production, and HVAC component fabrication.Aluminum flat tubes are automatically conveyed through precision roller guides, undergoing an integrated multi-stage process: straightening, precision bending, end necking, and high-speed cutting to produce finished tubular bent components. The system enables direct program storage and editing for rapid changeover between different tube specifications.

Product SKU: 3

Product Brand: DAG

5

Reviews

There are no reviews yet.