Machine Description

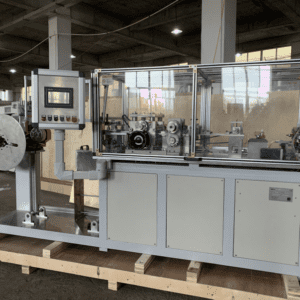

280 Meters/Minute High-Speed Automotive Radiator Fin Making Machine

This high-speed radiator fin making machine is equipped with the following advanced devices:

1. Automatic Decoiler

2. Precision Tensioning Unit

3. Adjustable Micro-Spray Lubrication System

4. Fin Forming Assembly

5. Pitch Control Forming Unit

6. Programmable Counting & Cutting System

7. Strip Demolding Detection Sensor

8. Jam Detection Device

9. Cutting Fault Indicator

10. Fin Forming Unit Overload Protection

11. Malfunction Indicator Light

| Product Name: | Radiator Fin-Making Machine | Coil Number: | 2-coil Type |

| Working Principle: | Rolling Mechanism | Control System: | PLC And HMI |

| Automation Level: | Fully Automatic | Feeding Speed: | 0-280 M/Minute |

| High Light: | Fin-making machine, Fin press machine | ||

Machine Technical Parameters

| Fully automatic High-Speed Fin Making Machine |

| Specification: GS280; |

| Max feeding speed: 280m/min; coil inner diameter: 300mm; double coil tray; |

| Fin cutting frequency: max 80 times/min; |

| DS800 micro-spray precision lubrication system (patent product); |

| Control system: Delta, Taiwan |

| Worker: 1 person; |

Technical Parameters of Fin Forming Roller

| Fin width | according to the customer’s requirement |

| Fin height H | according to the drawing |

| Fin pitch h | according to the drawing |

| Aluminum strip thickness β | 0.08mm |

| Opening width γ | according to the drawing |

| Opening angle α | according to the drawing |

| opening length L | according to the drawing |

| Fin R angle | according to the drawing |

| Fin shape | U shape |

| Aluminum strip material | AA4343/AA3003/AA4343 |

| Fin tooling blade material | cobalt-containing high-speed steel forged parts |

| Fin tooling blade service life | ≥250 million fin convolutions for pure aluminum strip |

Aluminum Fin Machine

The fin machine is controlled by an integrated PLC, AC servo system, and touchscreen HMI interface. Dedicated servo motors independently drive the fin forming unit, pitch forming device, collection system, and fin pulling mechanism. The counting device and cutting device are each powered by separate independent servo motors. This aluminum fin machine is engineered and manufactured by DAG Company in China, delivering exceptional value through cost-effective pricing and complete customization flexibility. We provide comprehensive turnkey solutions backed by professional technical support. With reliable worldwide shipping and dedicated service, we welcome your inquiries for customized manufacturing solutions.

Product SKU: 3

Product Brand: DAG

5

Reviews

There are no reviews yet.