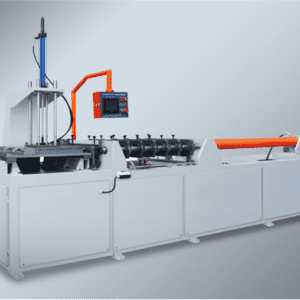

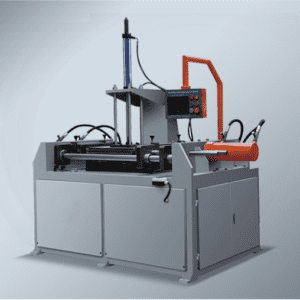

Machine Description

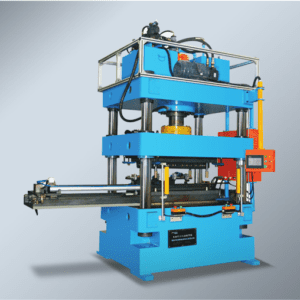

Fully Automatic Manifold Pipe Punching Machine

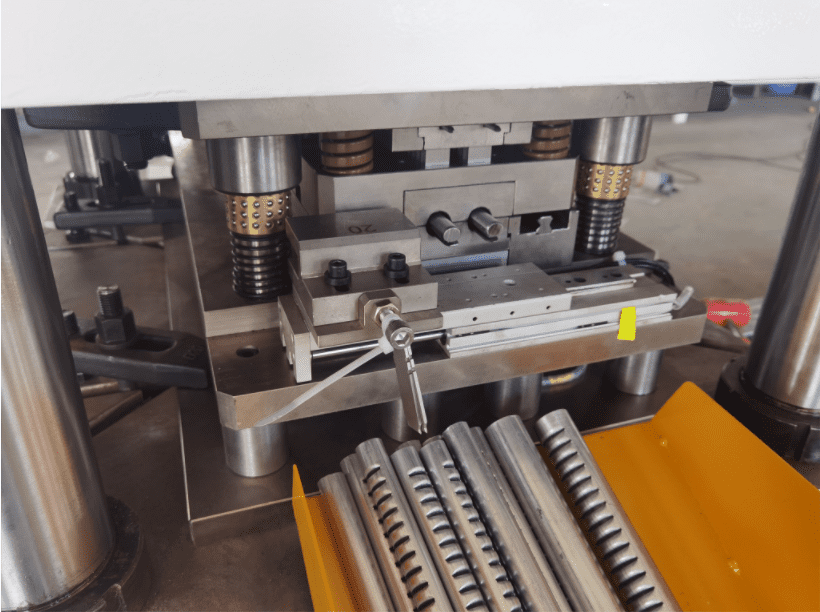

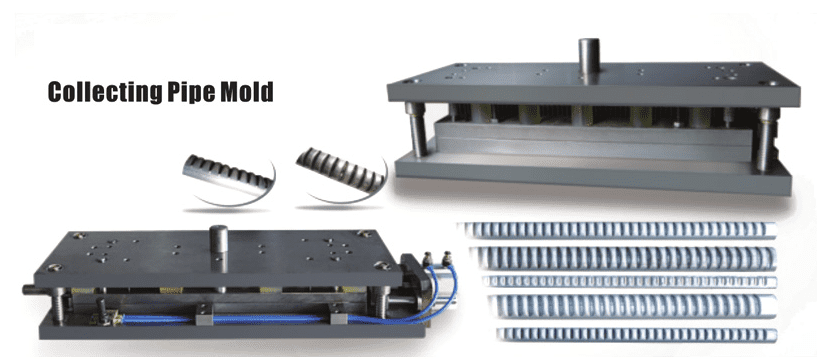

This fully automatic high-speed servo drive system can stably and continuously punch round, oval, and D-shaped aluminum or copper manifolds, 24/7. Quick-change dies accommodate any pipe with an outer diameter of ⌀1–50 mm, ensuring hole position accuracy of ±0.02 mm.

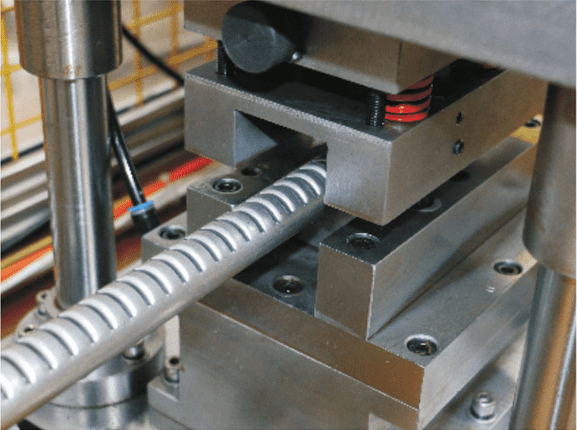

1. CNC Servo Feed: Hole spacing accuracy ±0.02 mm, infinitely programmable patterns

2. Quick-Change Chassis Die: Die changes can be completed within 5 minutes for outer diameters ⌀1–50 mm and wall thicknesses 1–3 mm.

3. High-Speed Steel Powder Metallurgy Punch Blades: 2 million punch life, burr ≤0.05 mm, no need for secondary deburring.

4. Vision Alignment: Real-time pipe rotation correction, achieving precise positioning of ±0.05 mm.

Manufactured by Shenzhen DAG Tech—customizable configurations, highly competitive pricing, worldwide shipping, and free process support.

Machine Technical Parameters

Automatic Manifold Pipe Punching Machine

| Workpiece specification | Diameter:φ1-50mm |

| Tube length:100-1000mm | |

| Flat tube hole Pitch | as per the customer’s requirements |

| Precision tolerance range | as per the customer’s requirements |

| Pipe Processed per time | 1-2 pcs/time |

| Operation method | Manual loading-Auto punching hole-Output |

| Production capacity | Around 60pcs/hour(Calculated with length 1m) |

| Drive mode | Servo+Pneumatic |

| Overall dimension | 2800*700*1800mm |

| Weight | 1.5 T |

Automatic Manifold Pipe Punching Machine

Fully-Automatic Manifold Punching Machine – engineered for rapid, stable and reliable perforation of both round and D-profile manifolds. Interchangeable, size-specific tooling is custom-built for any tube OD within minutes, guaranteeing ±0.02 mm hole pitch and burr-free edges for high-pressure brazing. Designed & manufactured by DAG Shenzhen—cost-effective, globally shipped.

Product SKU: 3

Product Brand: DAG

5

Reviews

There are no reviews yet.