Machine Introduction

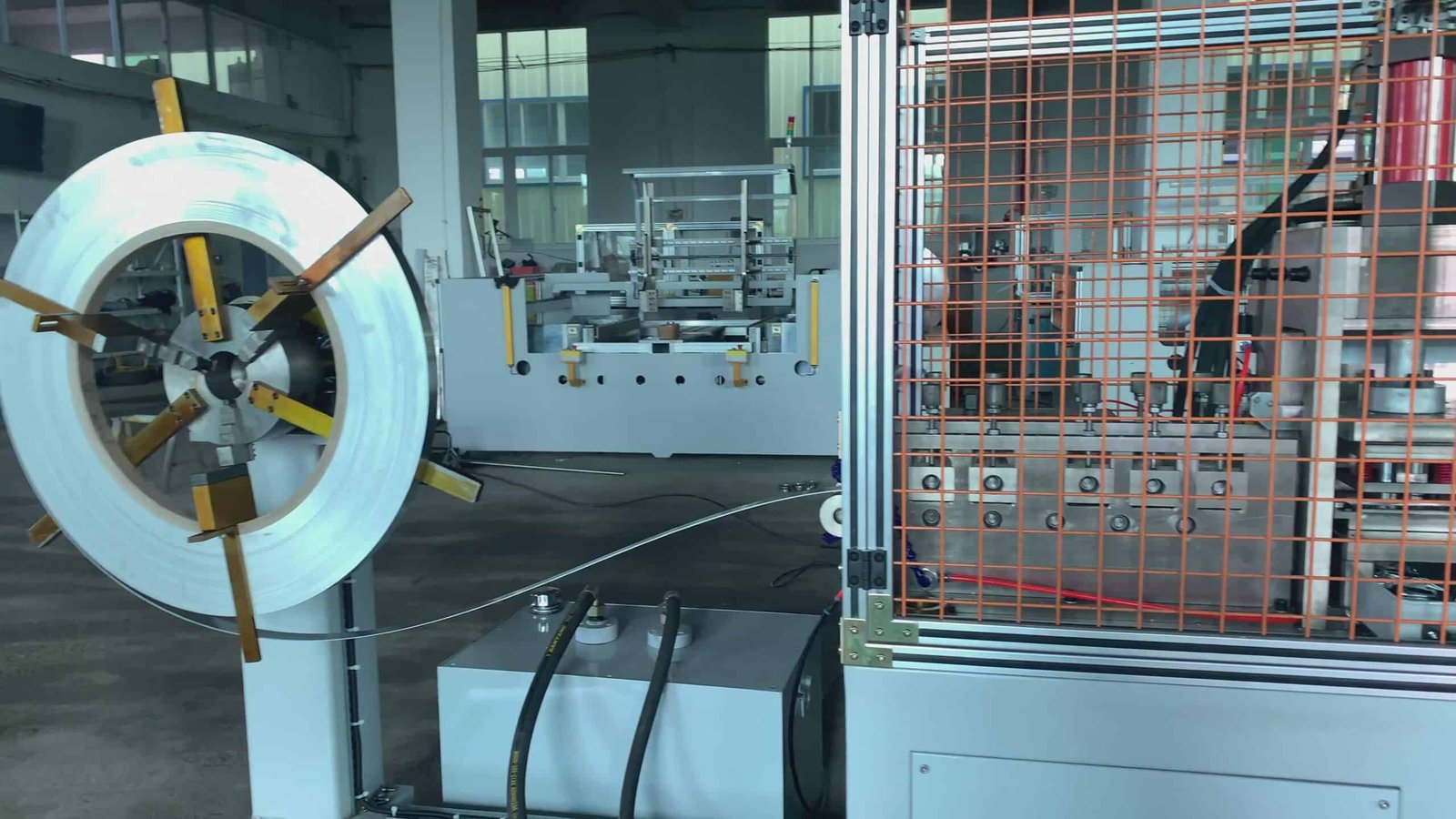

Automatic Aluminum Side Panel Forming Machine

This advanced forming machine automates the complete production cycle for side panels, processing aluminum coils through precision straightening, edge forming, punching, dual-end arc pressing, and automated cut-to-length operations. Tooling versatility enables rapid changeover for diverse panel profiles.

1. Application: Automotive radiator aluminum side panel production

2. Processes: CNC stamping, edge forming, hole punching, arc bending, cut-to-length

3. Material: Aluminum alloy sheets/coils

4. Automation: Fully automatic with PLC control

5. Industry: Auto parts manufacturing, heat exchanger production

Machine Technical Parameters

| Workpiece specification | Punching, Flanging, Uslot forming/Bending, Cutting(as per drawing’s requirement) |

| Workpiece length | 100-1000mm |

| Alu strip width | Per Workpiece unfold size |

| Loading coil dimension | Lnner diameter:min.400mm |

| Outer diameter:max.1200mm | |

| Plate Processed per time | One pc/Time |

| Decoding/Feeding/Straightening | Automatic |

| Lubricating Way | Automatic |

| Production capacity | 180 pcs/hour |

| Drive mode | Servo+Hydraulic+Pneumatic |

| Overall dimension | 5200*1000*1700mm |

| Weight | 3.8 T |

Automotive Radiator Aluminum Side Panel Forming Machine

Specialized forming machine for automotive radiator aluminum side plates. Coil-fed automatic side panel former with integrated straightening, punching, curving & cutting capabilities. Ensures stable, high-quality production for aluminum heat exchanger components.

Product SKU: 3

Product Brand: DAG

5

Reviews

There are no reviews yet.