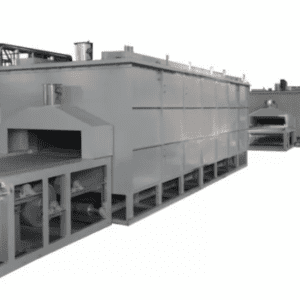

Continuous Aluminum Brazing Furnace For Brazing Radiator Intercooler Condenser

An aluminum brazing furnace system with a controllable atmosphere is mainly used for continuous brazing of aluminum water tanks, oil coolers, intercoolers, warm air, tubular condensers, evaporators, parallel flow condensers, cascade evaporators, air coolers of power stations under nitrogen protection atmosphere.

| Dimension(L*W*H) | Custom Made | Usage | Heat Treatment Furnace |

| Power (kW) | 400 | Conveying Belt Speed | 300~1000mm/min, Inverter Control |

| Total Oven Length | 35.5m | ||

| High Light | Continuous Nitrogen Brazing Furance, Car Aluminum Radiator Brazing Furnace, 400KW Aluminum Radiator Brazing Furnace | ||

Technical Parameters

| Serial number | Name | Length*Width*Height | Material |

| 1 | Spray zone | 7000*1360*250mm | The spray room is made of 304 Stainless steel; The masses are used low-carbon steel for welding |

| 2 | External size of drying furnace | 8000*1850*2000mm | The outside frame is processed and welded from low-carbon steel material |

| 3 | Internal size of drying furnace | 8000*1050*250mm | Internal plate 304 Stainless steel, thickness 2mm |

| 4 | External size of a burning furnace | 10000*2150*1900mm | The outside frame is processed and welded from low-carbon steel material |

| 5 | Internal size of a burning furnace | 1000*1050*250mm | Muffle 316L stainless steel, thickness of 8mm length. Use the whole sheet for bending without splicing |

| 6 | External size of air-cool room | 6000*1360*1900mm | Processed and welded from low-carbon steel material |

| 7 | Mesh belt | Width 1000mm Filament diameter3.2mm | Brazing zone 316L Other parts 304 Stainless Steel |

| 8 | The total length of the equipment | 35.5m |

Reviews

There are no reviews yet.