Machine Description

| Fin Type | Radiator Fin |

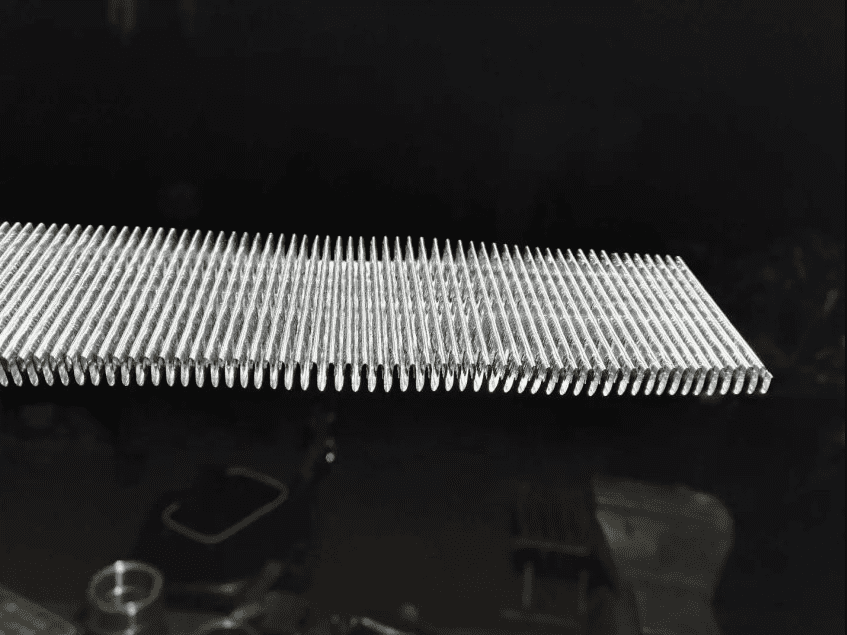

| Fin Height | 8mm |

| Fin Thickness | 0.08mm |

| Weight | 800kg |

| Voltage, Power | 220V/50Hz,2.5kw |

| Blade | Single Or Multi-combined |

| High Light | 0.08mm Thickness Radiator Fin Forming Machine, Radiator Fin making Machine,0.08mm Thickness low fin tube machine |

2mm Tube Wall Thickness Aluminum Radiator Fin Machine

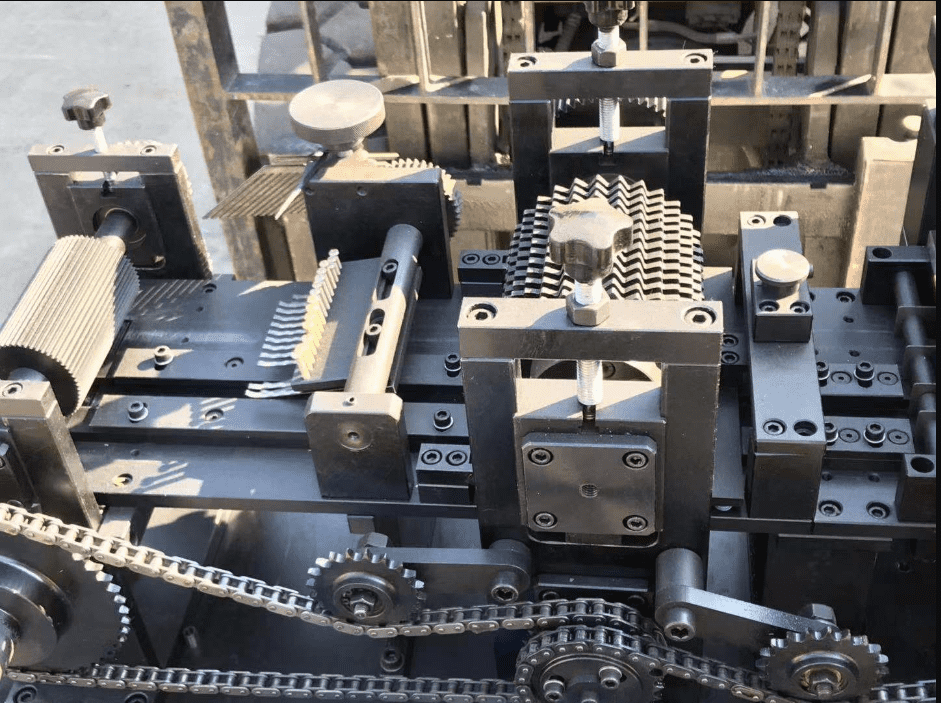

This aluminum fin forming machine employs combined fin forming rollers to produce corrugated heat dissipation fins for radiator applications requiring 2mm tube wall thickness compatibility.

The fin forming machine integrates the following modular devices:

1. Decoiler – Automatic coil uncoiling and material payoff.

2. Tensioning Device – Maintains consistent material tension throughout production.

3. Feeding Device – Precision servo-controlled material advancement.

4. Micro-spray Lubrication System – Applies controlled oil mist for optimal forming.

5. Fin Forming Unit – Combined roller dies for corrugated profile creation.

6. Straightening Device – Ensures final fin flatness and dimensional accuracy.

7. Cutting Device – High-precision shear for clean edge finishing.

Machine Technical Parameters

| Fin Type: | Radiator Fin | production efficiency | 60sec. |

| Workstation | 1 | Number of preset models | Non. |

| Machine weight | 800kg | Programmable | yes |

| warranty | 12 months | shape | unregular |

| mold | can customize | after-sale service | yes |

| Fin Height: | 8mm | brand name | DAG |

| Fin Thickness: | 0.08mm | Speed: | 100 M/min |

| Core Row Number: | 1-4 Rows | Voltage, power | 220V/50Hz,2.5kw |

| design style | can customize | running speed | adjustable |

| Driving mode | Servo pneumatic |

High-performance aluminum fin forming machine for 2mm tube wall thickness radiators. Combined rollers produce corrugated fins with precision. Integrated decoiling, tensioning, lubrication, forming, straightening & cutting.

Car Aluminum Radiator Fin Machine

This aluminum fin forming machine produces wavy fins for heat exchangers using an innovative combined-width fin-forming roller. As the machine's critical component, this adjustable roller design significantly reduces production costs and downtime by eliminating the need for frequent roller changes when manufacturing fins of different widths. Precision fin manufacturing for HVAC and heat exchanger industries. High-performance automotive aluminum radiator fin machines at competitive prices. 100% customizable to your specs. Contact us for a free quote today!

Product SKU: 3

Product Brand: DAG

5

Reviews

There are no reviews yet.