Machine Description

| Machine Name: | Radiator Core Builder Machine | Working Principle: | Pneumatic System And Servo |

| Radiator Core Width: | 200-680mm | Radiator Core Height: | 350-780mm |

| Time Needed For 1 Core: | 3 Mins | Follow-up Process: | Brazing Furnace |

| High Light: | Core builder machine, core assembly machine | ||

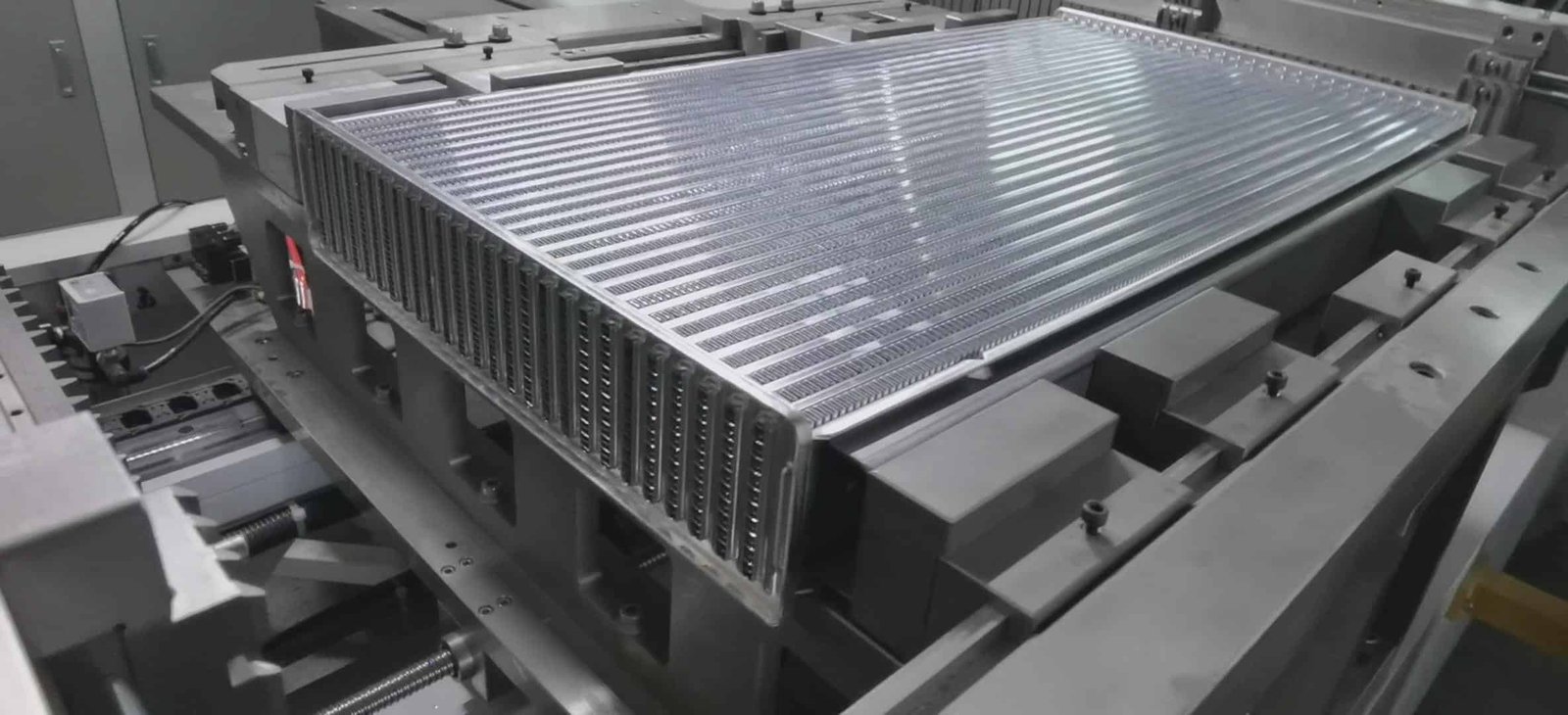

Our Aluminum Radiator Core Builder Machineis engineered for high-precision manufacturing of automotive and industrial cooling system cores. This advanced equipment automatically assembles aluminum flat tubes, aluminum fins, header plates, and side plates into a unified, production-ready radiator core.

Key Features

1. Integrated Header Compression System: Ensures uniform header-to-tube expansion for leak-proof joints and optimal thermal transfer.

2. PLC-Controlled Precision: Servo-driven alignment guarantees consistent core dimensions and fin density.

3. High-Quality Construction: Heavy-duty frame and wear-resistant components ensure 24/7 production reliability.

4. Adjustable Specifications: Quick-change tooling accommodates various core widths, heights, and row configurations (1-6 rows).

5. Automated Material Handling: Optional auto-feed systems for tubes and fins increase throughput by 40%.

Technical Capabilities

1. Core assembly cycle: 45-60 seconds

2. Compatible with tube widths: 16mm, 22mm, 26mm, 32mm

3. Fin pitches: 5-12 FPI (fins per inch)

4. Production capacity: 80-120 cores per hour

Applications

Ideal for manufacturing OEM-quality radiator cores for passenger vehicles, heavy-duty trucks, agricultural equipment, and industrial machinery. This machine delivers the precision and durability required for modern aluminum cooling system production.

Machine Technical Parameters

| Core Dimension | Core height direction:350-780mm |

| Core width direction:200-680mm | |

| Flat Tube Layers | One layer/2layers |

| Tube Laying Mode | Automatic Feed Into Material Silo/ Manual |

| Flat Tube Flaring Mode | Automatic /Manual |

| Fin Laying Mode | By fin tray /Manual |

| Production Capacity | Around 30sets/hour |

| Drive Mode | Servo /Pneumatic |

| Overall Dimension | 2300*2500*1800mm |

| Weight | 2300kg |

Aluminum Radiator Core Builder Machine for Car

Our Aluminum Radiator Core Builder Machineis engineered for high-precision manufacturing of automotive and industrial cooling system cores. This advanced equipment automatically assembles aluminum flat tubes, aluminum fins, header plates, and side plates into a unified, production-ready radiator core. Aluminum Radiator Core Builder Machine (with Upper Compression Function) - Customizable, cost-effective, global shipping. Inquire now!

Product SKU: 5

Product Brand: DAG

5

Reviews

There are no reviews yet.